Shuchi Shrivastava* Navin Carpenter#

* Shuchi Shrivastava, Lecturer, Department of Textile Technology, Shri Vaishnav Polytechnic College,

Indore (M.P.)

#Navin Carpenter, Student, Department of Textile Technology, Shri Vaishnav Polytechnic College,

Indore(M.P.)

ABSTACT

A brilliant that can occur with an global environment is a natural fiber, which is a natural fiber, which can be considered a potential candidate for most modern popular products that are seriously threatened to our environment. The area of Jute (and the jute to achieve the work of Jute, is the growth market of natural fibers to the industrial application provided by Jute products and can satisfy stringent quality specifications, and quality / production has been improved. Lighters and the best jute organization. At the same time, we need to apply new technologies to use new technologies to use jute in technical fibers, composite materials and other industrial applications to create new technologies. Diversified fiber and adaptation are the latest products with better standards You can develop a new market to meet your requirements. This requires product development and market development with trust, depending on strict quality standards and technical characteristics. Work on new products and technologies should focus on suitable and cost-effective solutions with a full understanding of the inherent strength and function of jute fibers. In addition to research and development for new products and better technologies, it is necessary to continuously improve the design and quality of products and to maintain and expand the existing market share in order to respond to the ever-changing market.

Keyword: Technical Textiles, Natural Fibers, Jute, Advance Spinning

INTRODUCTION

Jute is the common name given to fibers obtained from the bark of two cultivars of the genus Co chorus. Jute is grown in the alluvial plains of tropical and subtropical regions of South Asia. India alone accounts for about 50% of global jute and related textile production.

Jute grows to a height of 2.5 to 3.5 m when mature. Jute fibers are extracted from the stems of plants through a microbiological process known as retting. Soaking jute in normally running water can also be done chemically. A typical fiber yield based on the stem derived is about 6% by weight.

PHSICO-CHEMICAL PROPERTIES OF JUTE

Physical Properties of Jute:

1. Microscopic appearance: jute is a multi cellular fiber. Individual fibers show knots and cross marks in the longitudinal section and polygonal shapes in the cross section. The lumen is wider than the cell wall and there is a marked constriction (non-uniform thickness) in the cell wall. The lumen expands at the ends of the fibers, making the cell wall very thin. On the outside, the fibers are smooth and shiny.

2. Density: Fiber density 1481.50 g/cm3.

3. Elasticity: Jute has low elasticity due to its stiffness and stiffness. The advantage of using jute as a packaging material is that it retains its shape during loading.

4. Length and Diameter. One jute fiber has an average length of 0.1 inches and an average diameter of 12

microns. The average ratio of length to width is about 90.

5. Moisture recovery: Jute is inherently highly hygroscopic. Moisture recovery is 1214% under standard conditions.

6. Composition: Jute fiber contains cellulose (55-63%), hemicellulose (20-24%) and lignin (12-14%).

7. Elongation: Jute does not stretch noticeably when stretched. The elongation at break is 11.2% under normal atmospheric conditions.

8. Strength: The strength of jute varies from 3.57 g/denier.

9. Conductivity: It is a very good insulator of heat and electricity.

10. Color: Varies from yellow to brown to gray depending on growth and loss conditions. Chemical

Properties of Jute Fiber:

1. Exposure to sunlight: When jute is exposed to sunlight, it gradually acquires a yellow color. This is due to the color change within the fiber associated with the lignin molecule.

2. Microbial action: Jute is more resistant to microbial attack than gray cotton or linen. Slightly cleaning the protection effect of lignin is perfectly resisted. Sometimes the jute fabric treated with a Dubmamonium solution and then dried to make the film of green color as a more rotting material.

3. Action Alkali: Strong alkali deteriorates their power. Jute loses weight when boiling with diluted eating soda. The loss is mainly related to hemicellulose removal.

4. Exposure to Heat: Jute, like other textile fibers, does not decompose when exposed to heat. However, with prolonged heating, the fiber quality deteriorates.

5. Action of Acids: Organic acids such as oxalic acid and formic acid, and inorganic acids such as sulfuric acid and hydrochloric acid do not react in dilute form under normal or low temperature conditions. In the case of strong acids, when boiling, hydrocellulose is formed.

6. Action of Oxidizing Agents: Normal oxidizing agents do not act on jute.

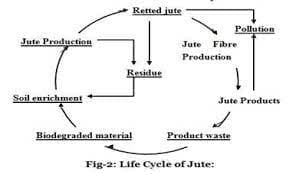

LIFE CYCLE OF JUTE

Jute’s lifecycle analysis has not yet been analyzed as sufficient experimental data tested at the international level of an authorized laboratory. It is not a standardized international level as a detailed scientific data supported by true experiments after the standard protocol of standard protocols that can assess credit value. As a result, other questions and doubts remain still, but there are some available data, which indicates that biodegradability and environmentally friendly, and show positive criteria for carbon at many stages. However, built-in studies should be acceptable at the international level.

The picture is obviously partially organic, environmentally friendly in nature, soil and biodegradability, but sufficient scientific data and evidence assistance must be made for international adoption. Jute fibers can be considered as fibrous composites with anisotropic cellulose microfibrils acting as carrier elements in an isotropic lignin matrix, and hemicellulose acting as a binder between them. Cellulose is a linear condensation polymer in which D anhydroglucopyranose units are linked by 1. 4 glycosidic bond. The degree of cellulose polymerization of jute is considered to be the lowest among plant fibers, about 1100-1150.

SALIENT FEATURES OF JUTE

Jute is a lingo cellulosic natural fiber. It is organically decomposed into eco-friendly fibers and can be

disposed of in landfills, and can be easily and safely incinerated without leaving toxic gases or residues. Textiles are reusable and disposable. It is an annual renewable natural product, so it does not require the world’s scarce energy resources. The fibers are strong and durable. The products are aesthetic, versatile and nature-friendly. Jute fiber has high strength and modulus, low elongation, remarkable water capacity of almost all types of dyes, good heat resistance and uneven surface morphology.

APPLICATION OF JUTE IN TECHNICAL TEXTILES

1. Home Textile

Unique natural color, special handmade appearance, heavy and delicate appearance, high strength and

modulus, medium to good drape, good hygroscopicity, good bleaching property, good dyeability and printability with various dye grades, low cost, solubility, agricultural reproducibility, eco-friendly friendly .

Uses: Multi-coloured/bleached, dyed, printed and processed jute or jute/cotton upholstery and upholstery fabrics, tapestry, wall coverings, floor coverings, floor mats, soft suitcases, aprons, hats, gloves, folder covers, shoes, tablecloths, fashion accessories Lace, patchwork and weaving, gift boxes and various handicrafts made from jute fibers, yarns and fabrics. Environmentally friendly jute upholstery fabrics and tarpaulins made from jute or mixtures.

2. Geo Textiles

High strength and modulus, good dimensional stability and ability to withstand the initial stresses of road structures, heavy and substantial thickness, good drape quality, rigid body, prevention of uneven settlement in the ground, high dielectric constant and transferability, uneven surface morphology, prevention Lateral and rotational sliding, high absorbency, suitable for soil filtration, drainage and strengthening (caking), soil affinity and addition of nutrients to the soil after decomposition, environmental friendliness, vegetation support, easy access, low cost and ability to regenerate agriculture.

Uses: Jute Geotextile (JGT) is applied in surface soil erosion control on slopes and plains, embankment stability, subsoil reinforcement of roads, river and waterway embankment protection, underground drainage, soft ground reinforcement, etc. Thus, the JGT bears the load. In the construction phase, it prevents the mixing of different soil layers, acts as a separator, performs a filtering function, and controls cross-scattering, subsidence and landslides.

The JGT performs five main functions: segregation, filtration and drainage, initial reinforcement, surface soil and vegetation segregation control, or biotechnology support.

3. Agro Textiles

High strength and good dimensional stability, good drape quality, easy dispersion of kinetic energy of raindrops, good water absorption and wind damping, improved microclimatic conditions (i.e. temperature and humidity), increased organic matter and nutrient levels in soil. , uneven surface morphology to prevent lateral and rotational slip, high dielectric constant and air and water permeability, support for vegetation and biotechnology, environmental friendliness and soil friendliness, easy accessibility, low cost and agricultural renewable potential.

Uses: Jute fabrics are currently used as sunscreens, plant nets, windscreens, harvest nets, field nets for crop protection from birds, weed control, seed mulch, soil conservation, forest development in semi-arid

areas, nursery pots, etc. network, etc.

CONCLUSION

The growth strategy therefore aims to diversify and launch value-added jute, textile and non-woven products for a variety of applications. Product development and market development will effectively promote the widespread use of jute, along with ensuring the highest quality and increasing consumer awareness of the benefits of jute worldwide.

Meeting the needs of this sector requires the development of a much wider range of jute yarns and fabrics using different technologies.