Abstract

A versatile material which has created outstanding attention among buyers of apparel, footwear and furniture because of its flexibility and durability4

properties. Excluding the features of leather, the steps is involved in its manufacturing having huge impact on the surroundings. In contrast to the newest leather made from mushroom technology, the usual leather accounts for higher ecological footprints. The emergency of innovative fabrics formed from mycelium of mushrooms is really expected to have huge demand in market in upcoming generation. This context emphasizes about the processing methods involved in designing of mushroom leather, advantages over animal leather and its influence on environment.

1. Introduction

Leather is a well-known material in field of clothing, furniture, accessories, and footwear. On account of its long-lasting, versatility and good comfort it has huge estimation in market with business value of US$ 100 billion per year. Traditionally the raw materials that take part in processing are animal skins which make the leather industry to depend on by-products of dairy and meat industries. Subsequently the leathers are tanned and processed under several conditions which releases toxic chemicals that accounts for carbon emissions and playing a significant role in greenhouse effect. A latest competitor has emerged in the market showcasing the modern technologies by replacing the leather derived from animals with sustainable and environment friendly leather. The innovative product that completely removes usage of chemicals, reduction in carbon emissions, on the other hand having the supremacy such as recyclable, flexible and can able to mimic the standard leather is simply awesome. In this article, discussion is made on the process included in production of alternate leather with its impact on surroundings and benefits over animal leather.

2. Implementation of an exceptional ingredient

Labels such as sustainable, environment friendly, renewable and organic are well suited for the

innovative class of textile “Mushroom Leather”. Apart from the application of fungi in medical science, edibles and bio fertilizers the compound multicellular organisms are utilized in making of an eco-friendly product. Varieties of mushrooms exist in the environment having divergent properties in which some accounts for nourishment and other set of species used for medicinal purpose [7] (Mitchell P, Tien, Chaitali, F, & John , 2017). In this case, mushrooms are primal matter in processing of the sustainable leather as they own the competency to grow mycelium underneath them.

3. Under grown network of hyphae

Mycelium is the largest living structure on the globe occupies nearly 10 Kilometer square in Oregon’s Blue Mountains. Mycelium, the vegetative constituent of fungus incorporated with matrix of filaments. In other way, the term mycelium is defined as root like structure under covering mushroom. The process of developing the network of such delicate white strands requires minimum dissipation of energy and resulted trash can be recycled [2] (J, T, Rames, & Kavitha, 2015).

Figure 1: Network of white threads (Mycelium) (Source: Pixabay – https://pixabay.com/photos/mushroom-mycelium-small-mushroom-3835397/)

4. Construction of an eco-friendly substitute

4.1 Preparation of substrate

During the processing of mushroom leather, the surface on which the mushroom grows should be

dampened. Mushrooms are included with organic wastes such as saw dust, straw and corn. The company named MycoWorks mixing agar along with mushrooms whereas Mycotech uses saw dust. Wet substrate makes easier for the mushroom to append with the organic inclusions and develop. The growing conditions can be tuned to produce composites of varied sizes, shapes and performance of the outcome [3] (Madaria, 2018).

4.2 Development of mycelium

The process of developing mycelium also eliminates the involvement of overpriced and cosmopolitan methods. Following cleaning process, the wastes are mixed with a minute, reproductive unit of mushroom and covered. Mycelium grows at an exponential rate ranges from four to nine days [4] (Mitchell P, Antoni, Sabu, & Alexander, 2020). Other factors also modify the growth of mycelium is variety of mushroom, humidity and temperature [3] (Qua, 2019). The cells ultimately having tightly interlaced mycelium that grows into a bundle of thread-like structures with interconnections which are highly responsible for material strength. Prior to drying and utilization, the final material is compressed to obtain needed size and shape [4] (Mitchell P, Antoni, Sabu, & Alexander, 2020).

Figure 2: Tightly interlaced pack of mycelium (Source: Network of Deutsche Welle)

5. Contrasting characteristics of mushroom leather

5.1 During processing

In the premature stage of process, modification of substrates and alteration of growing conditions is possible [1] (Haneef, Luca, Cloudia, Jose, & Athanassia, 2017). The material can be grown in vertically stacked layers results in better use of space. Polyvinyl chloride or PVC leather [3] (Qua, 2019) is produced by chemical alteration of vinyl polymer whereas the mycelium based leather eliminates the usage of chemicals during processing. The process implements minimum usage of water less than one tenth of water used in typical leather production. Mycelium fabrics have ability to form the resultant fabric with different textures, sizes, finishes and complex shapes to acquire desired characteristics.

5.2 Advantages of mushroom leather over typical leather

The time required in latest manufacturing technology is very less compared to typical process. Growing cattle for skin (raw material) may take three years to produce fragment of leather while the growth of mushrooms is rapid. Hence raising livestock is not involved in fungi-derived leather [3] (Qua, 2019). Less carbon emissions and processing with minimum amount of chemicals are the added advantage. It helps in controlling properties such as texture, strength, elongation, orientation and unmatched finishes [6] (Madaria, 2018).

Figure 4: Brown Natural leather (Source: Myco Works Inc. – https://www.madewithreishi.com/products)

Mycelium has the potential to construct large-scale structured (macro structured) fabrics which are robust and pleasant to breathe. Contribution of animal agriculture in greenhouse gas emissions is more considering mycelium has a soft connection to the environment from initial to final stage. The watch straps of mushroom leather can prevent skin annoyance due to eczema. The light mycelium based leather also has more absorbency compared to its competitor [4] (Mitchell P, Antoni, Sabu, & Alexander, 2020).

Table 1: Properties of mushroom based leather compared to cowhide leather

(Source: https://www.madewithreishi.com/stories/performance-results-q120)

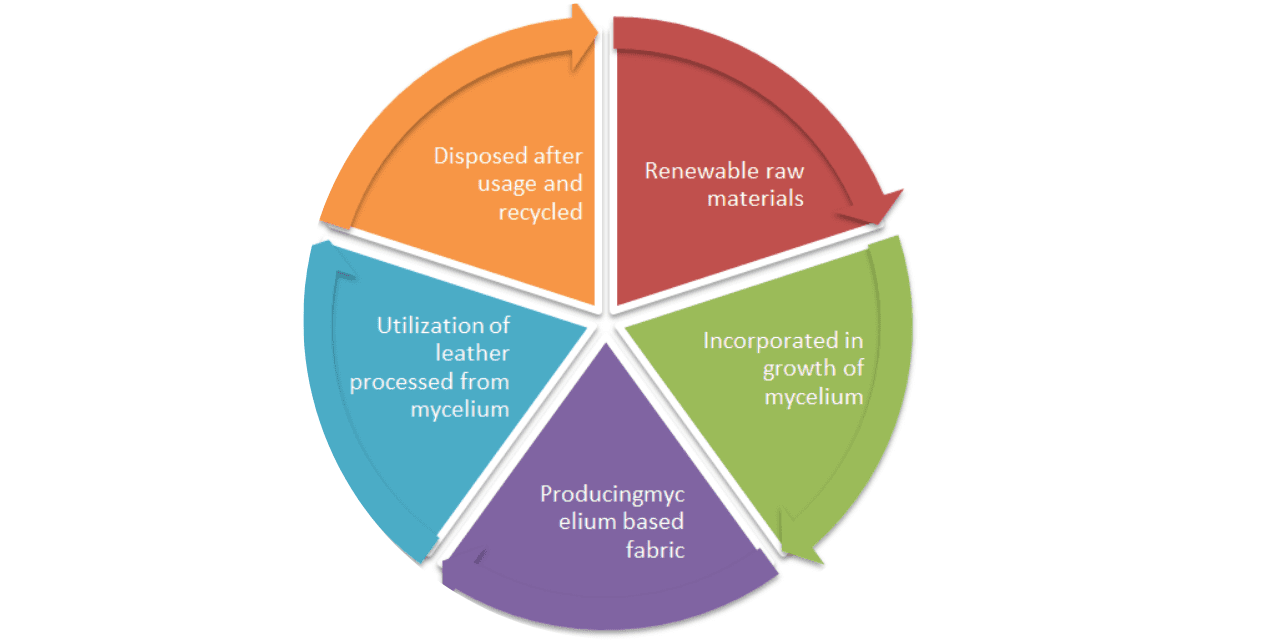

6. Environmental impact of mushroom technology

The whole process of fabricating the mushroom leather happens in a closed loop manner. The term closed loop means that the raw materials employed in the process acquired from post-consumer waste and made into recycle and adapted to use into a variety of products [3] (Madaria, 2018). Growth substrates incorporated such as saw dust, corn and straw are usually by-products of agriculture which facilitates creative re-use. The effective growth of mycelium is achieved by organic process that makes up the leather like composite with low impact on the environment [6] (Qua, 2019).

Figure 5: Illustration of eco-friendly nature of mushroom leather

7. Conclusion

The process of making leather from mushrooms that too inclusive of renewable ingredients and customization technology is really unprecedented. With the constantly evolving technologies, the leather alternative is expected to have an extraordinary market in future. In addition to enormous benefits, the mycelium based materials have least impact on the environment that making it superior over typical leather. The mushroom leather has been produced in small scale now; when it starts to be manufactured in extensive volumes then customers will highly get attracted to such sustainable fashion.

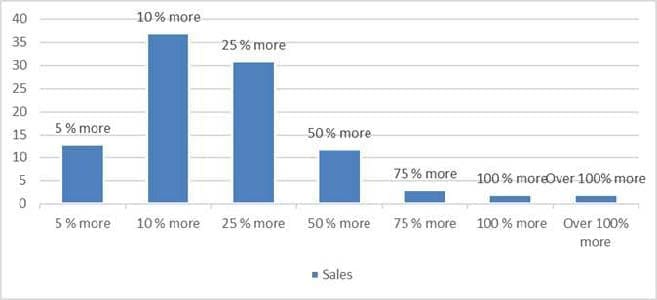

Figure 5: Percentage more people ready to pay for sustainable fashion (Source: Survey on global perspective by KPMG)

Also we can state that money is the big concern in switching to sustainable fashion, if there is reduction in cost, hope the leather can draw much attention from buyers [13]. Every individual should aware about the term “Eco-conscious”. Once they started to show concern on the environment then green could be the incredible trend in the world.

References

- Haneef, M., Luca, C., Cloudia, C., Jose, H.-G., & Athanassia, A. (2017, 01 24). Advanced Materials From Fungal Mycelium: Fabrication and Tuning of Physical Properties. Scientific Reports, 7. doi:10.1038/srep41292

- J, K., T, S., Rames, P., & Kavitha, S. (2015, 02 15). Eco-friendly waste management strategies for greener environment towards sustainable development in leather industry: A comprehensive review. Journal of cleaner production. doi:10.1016/j.jclepro.2014.11.013

- Madaria, D. (2018). I search paper: Mushroom Leather.

- Mitchell P, J., Antoni, G., Sabu, J., & Alexander, B. (2020, 09 07). Leather like material biofabrication using fungi. Natural sustainability. doi:10.1038/s41893-020-00606-1

- Mitchell P, J., Tien, H., Chaitali, D., F, D., & John , S. (2017). Mycelium Composites: A Review of Engineering Characteristics and Growth Kinetics. Journal of Bio nanoscience.

- Qua, F. (2019). Qualitative study on sustainable materials for design through a comparative review of leather and its modern alternatives.

- Stamets, P. (2005). Mycelium Running: How mushrooms can save the world. NewYork: Ten speed press.

- “Bolt Threads – Mylo.” Bolt Threads, Bolt Threads Inc., http://www.boltthreads.com

- Reishi™: https://www.madewithreishi.com/products

- Myco Works https://www.mycoworks.com/our-products#an-advanced-materials-platform

- Mushroom Leather is more than a sustainable alternative to animal skin by Katherine Saxon https://wtvox.com/fashion/mushroom-leather

- Eco vative design: https://ecovativedesign.com/

- Sustainable fashion, a survey on global perspectives by KPMG, FASHION SUMMIT.

Author:

LOGA SUBRAMANI A. A. RAYBAGI (B. Tech T.T.)

A. RAYBAGI (Tech T.T. Assistant Professor in Textiles)

DKTE’S Textile & Engineering Institute, Ichalkaranji