Institut für Textiltechnik of RWTH Aachen University, Aachen, Germany

- Introduction

During demonstrations and riots, more and more fire bombings are carried out with Molotov cocktails. Apart from damage to property such as house or car fires, personal injuries are also caused. Increasingly, police and fire brigade personnel suffer damage from Molotov cocktail explosions. These explosions result in serious injuries, some with fatal consequences. [1–11]

Molotov cocktail attacks (MCA) are counted as “politically motivated crime, especially bodily harm and homicide” [12]. In 2020, the MCA increased by 18.82 % compared to the previous year [13].

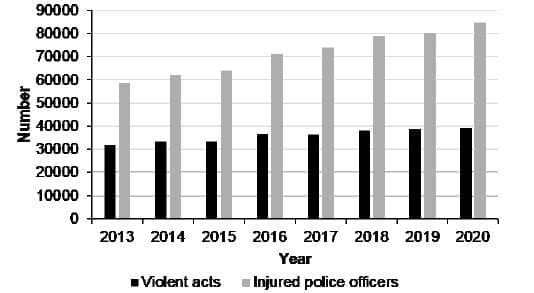

Figure 1 shows the development of the number of violent offences per year in comparison to the number of injured police officers (PVB). It can be seen that the number of injured persons increases more than the number of violent acts carried out [14].

Figure 1: Development of violent attacks on German police officers [14]

The personal protective equipment (PPE) of a police member is mostly made of aramid blend fabric. The melting temperature of aramid is 600 °C [15]. A Molotov cocktail explosion reaches higher temperatures between 800 °C and 1700 °C [16, 17]. When PPE made of aramid is exposed to these temperatures, the material contracts, it shrinks and it begins to decompose. The melting material itself causes severe injuries to the skin [18]. The parts of the body exposed by the shrinkage are defenceless against direct fire.

To improve the protective effect of PPE against MCA, research is being conducted on a new fibre material, new fabric patterns and a new coating [19]. However, this article focuses on the development of new fabric patterns.

The new fabric should offer the police officers at least the same protection as the old fabric and additionally reduce the shrinkage. The current tasks of the PPE include [20]:

– Protection against cold

– Stab resistance

– Wearing comfort

– Impact resistance

– Fire protection

– Freedom of movement

– Wind and rain protection

– Easy care

– Abrasion resistance

Air permeability and tear resistance are determined in order to better assess cold protection, stitch resistance and wearing comfort. The air permeability and tear resistance are determined to compare the new weaves and to find a possible correlation between air permeability and tear resistance. High air permeability increases comfort. The tear strength is needed to assess the tear resistance.

- Experimentation

In the following, the execution of the tests (Determination of tear force of trouser-shaped test specimens according to DIN EN 13937, air permeability according to DIN EN ISO 9237) is explained. First, the new bindings with which the tests are carried out are presented. For each experiment, the experimental design, execution and results are explained.

2.1 New fabric patterns

When PPE is exposed to the high temperatures of a Molotov cocktail explosion, the material shrinks. The shrinkage of the textile causes the material to contract and the garment to fit tightly around the skin. The insulating effect of the air cushion is lost. Areas of the body such as the ankles or wrists are exposed. Direct contact with the fire causes severe injuries to these parts of the body. Textiles used to make fire-retardant clothing are currently made of aramid fabrics with a 3/1 twill weave [15]. Independent of a new material for PPE, three new fabric weaves have been developed. These weaves should have a maximum shrinkage of 1.5 %. The wearing comfort should still be given or improved with the new material [19]. In order to assess the influence of the weave on the properties of the fabric independently of the material, the three new weaves were developed and woven from m-aramid yarn. The weaves were developed by the project partner Sächsisches Textilforschungsinstitut e.V., Chemnitz, Germany (STFI).

Table 1: New types of fabric weaves (black: warp lift, white: warp lowering).

Weave No. 1 consists of a combination of rep elements. The resulting ribs lead to a high thread density. The weave points of the first weave are close together.

Weave No. 2 is a combination of the plain weave and its simplest variants, the rep and the panama weave. The plain and rep elements give the fabric structure and stability. The larger Panama weave elements create a float as the weave points are further apart.

Weave No. 3 combines two twill weaves. A twill with a Z degree is interrupted by a twill with an S degree. Untypical for the twill weave is that there are the same number of warp and weft threads on each side. The side of the fabric does not influence the property profile.

2.2 Determination of the tear strength

For the initial assessment of the new weaves, only small amounts of fabric are woven (an area of 600×1000 mm per weave). The leg tear test is carried out in accordance to the DIN EN ISO 13937 standard.

Samples with dimensions of 50 mm x 200 mm are taken from the fabrics. Two sets of five samples per fabric are taken. One set of samples in warp direction and one in weft direction. According to the standard, in one set of samples no two samples should contain the same warp or weft threads. Due to the small size of the woven fabrics, the arrangement of the samples cannot be done according to the standard. To determine the tear strength across the warp, only four instead of five samples can be taken from weave No. 3. The tests are carried out in a standard climate at 20.7 °C and a relative humidity of 66 %. [21]

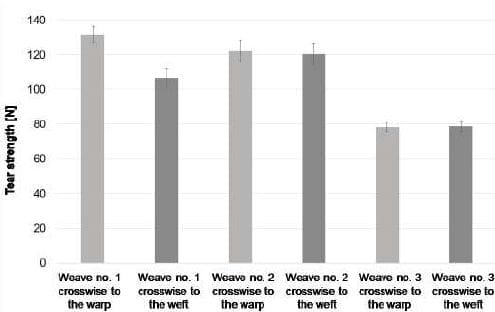

Weave No. 1 achieves the highest tear strength crosswise to the warp (131 N). The thread density is very high due to the interlocked rep weaves. The characteristic ribs form a tight weave with many, closely spaced weave points. The visible difference in tear strength across the warp and across the weft is due to the different orientation of the ribs in the fabric.

Weave No. 2 (120-122 N) and weave No. 3 (78 N) have almost the same tear strength in both directions. The reason for this is the symmetrical construction of the weave cartridges. Weave No. 2 consists partly of the plain weave and the Panama weave, which have the same properties in both warp and weft directions. In weave no. 3, the symmetry of the fabric results from the combination of the Z and S degrees, as well as the even distribution of the warp and weft threads. In Figure 2 the tear strength of the different fabric is shown.

Figure 2: Tear strength per weave and direction

2.3 Determination of air permeability

The testing device offers sufficient space to test the fabrics non-destructively. After each test, the fabric is moved alternately by 20 cm in the warp and weft directions. This means that the test preparation and the determination of the air permeability are carried out as per the standard. The tests take place in a standard climate at 20.7°C and a relative humidity of 66%. The fabric is clamped into the 20 cm2 test area for each test. Care is taken to ensure that there are no folds and that the edge seals the test surface from the environment. A differential pressure of 200 Pa is applied to the sealed sample and the air permeability is determined. For each fabric, a reference measurement is taken with a rubber plate to determine the leakage rate. The leakage rate is a measure of how much air escapes through the seal. This value is subtracted from the measured values to determine the actual air permeability. [22]

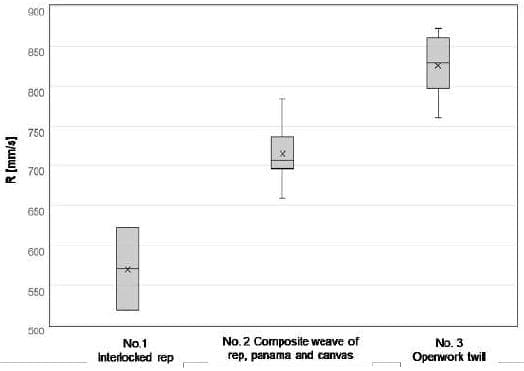

Figure 3 below shows the results of the tests to determine the air permeability for each of the new fabric weaves.

Figure 3: Results of the air permeability tests

Weave No. 1 achieves the lowest air permeability (518-631 mm/s). The combination of the rep elements results in a high thread density with closely spaced weave points. This makes the fabric strong and has a higher air resistance.

Weave No. 2 is a mixture of a plain weave and rep weave, with a high thread density and a Panama weave with slight floatation. The result is a fabric with medium air permeability (660-785 mm/s).

The highest air permeability is achieved by weave no. 3 (760-873 mm/s). The third weave has the lowest number of weaving points as a combination of two twill weaves with Z and S degrees. The unbound thread length is not very long compared to the atlas weave. The uniform geometry of the Z- and S-grades creates large areas of unbound warp and weft threads, which increase air permeability.

- Summary

PPE for riot police in Germany consists of an aramid blend fabric. The melting temperature of aramid is about 200 °C to 600 °C below the temperature reached by a Molotov cocktail explosion. The protective effect of PPE against Molotov cocktail attacks (MCA) is to be improved through research and development of new materials and fabric weaves. The basic properties of PPE are to be retained. The basic properties include comfort, protection against cold and stab resistance. In order to assess these properties, the air permeability and tear resistance are determined for three newly developed fabric weaves. The fabric weaves are combinations of the three basic weaves. The tear strength is determined across the warp and across the weft. The highest tear strength across the warp is achieved by weave No. 1, the lowest by weave no. 3. Across the weft, weave No. 2 achieves the highest tear strength, the lowest strength achieves weave No. 3. In order to fulfil the requirement for PPE for tear resistance, the tear strength across the weft must be at least 45 N and across the warp 45 N. Overall, the lowest tear resistance in both directions is 78 N. Thus, the requirement is fulfilled for all three weaves.

The highest air permeability is achieved in weave No. 3 and the lowest in weave no. 1. A direct correlation between air permeability and tear strength cannot be determined. Weave No. 3 has the highest air permeability and the lowest tear strength transverse to the warp and weft direction. The high air permeability of the three weaves of over 550 mm ⁄s increases the wearing comfort. The air cushions created during wear have an insulating effect. The air cushions store body heat and thus protect against cold. In case of contact with fire, they transmit heat more slowly than without air cushions.

- Outlook

To redesign a PPE that protects against MCA, the influence of the weaves on the shrinkage of the tissue must be determined. Due to shrinkage, the fabric of the current PPE contracts sufficiently to expose body parts. These unprotected parts of the body, such as the wrists or ankles, are then burnt by the fire of the explosion. In addition, a material must be developed that can withstand the heat of a Molotov cocktail explosion. Resistance to the heat can be achieved either by a higher melting temperature or by lower shrinkage and good insulation through air cushioning. Lower shrinkage means that no parts of the body come into direct contact with fire. The air cushions conduct the heat more slowly. A higher melting temperature means that the material does not decompose as quickly. This means that the other protective measures against fire remain intact.

Acknowledgement

The Institut für Textiltechnik of RWTH Aachen University would like to thank the AiF Projekt GmbH, Berlin for having the Project “Schutzmaterial für Einsatzkräfte – Molotowcocktailschutz” (No. 20599 BG) on behalf of the Forschungskuratorium Textil e. V., funded by the Federal Ministry of Economic Affairs and Climate Action (BMWK) of Germany on the basis of a decision by the German Bundestag

References

[1] Jager J.; Klatt T.; Bliesener T. NRW-Studie zur „Gewalt gegen Polizeibeamtinnen und Polizeibeamte. Die subjektive Sichtweise zur Be-treuung und Fürsorge, Aus- und Fortbildung, Einsatznachbereitung, Belastung und Ausstattung: Kiel, 2013.

[2] Schwetje, S. Ausschreitungen im nordirischen Londonderry. https://www.n-tv.de/ticker/Ausschreitungen-im-nordiri-schen-Londonderry-article21263687.html (Accessed April 19, 2022).

[3] Otruba, F. POL-Pforzheim: (FDS) Horb – Glücklicherweise nur geringer Schaden nach Wurf mit Molotow-Cocktail in Richtung Polizeigebäude. https://www.presseportal.de/blau-licht/pm/137462/4585984 (Accessed April 19, 2022).

[4] Mladek, J. Brandanschlag auf Polizeirevier in Greifswald. https://www.nordkurier.de/mecklenburg-vorpommern/brandanschlag-auf-polizeirevier-in-greifswald-0839626006.html (Accessed April 19, 2022).

[5] Kramper, G. Unruhen nach dem Tod von George Floyd. https://www.stern.de/panorama/stern-crime/new-york–junge-frau-schleudert-molotowcocktail-auf-polizeiwagen-9283384.html (Accessed April 19, 2022).

[6] Spilker, I. Freund oder Feind? https://www.torial.com/isabell.spilker/portfolio/376848.

[7] N.N. Verfassungsschutzbericht Bayern 2016: München, April 2017.

[8] N.N. Politisch motivierte Konfrontationsgewalt – Auseinandersetzungen zwischen links- und rechtsorientierten Akteuren in den Jahren 2011 – 2012 / Auszüge aus dem Abschlussbericht, 2016.

[9] N.N. Straftaten gegen Polizeibeamte – Lagebericht 2012: Dresden, April 2013.

[10]N.N. Straftaten gegen Polizeibeamte – Lagebericht 2011: Dresden, Mai 2011.

[11] N.N. Straftaten gegen Polizeibeamte – Lagebericht 2010: Dresden, Februar 2011.

[12] Waffengesetz (WaffG) Anlage 2 (zu § 2 Abs. 2 bis 4) Waffenliste, 2002.

[13] N.N. 1 Politisch motivierte Kriminalität im Jahr 2020: Bundesweite Fallzahlen, May 04, 2021.

[14] Gewalt gegen Polizeivollzugsbeamtinnen und Polizeivollzugsbeamte: Bundeslagebild 2020, 2020.

[15] N.N. Technische Lieferbedingungen Polizei des Landes Nordrhein-Westfalen: TLP Nr. 9004, 03.2019.

[16] Schröter, T. Bilddatengestützte Erkennung von Deflagrationen: Hamburg, 2016.

[17] Grabski, R.; Brein, D.; Pasch, U.; Neske, M.; Kunkelmann, J. Brandschutzforschung der Bundesländer,: Karlsruhe, 2010.

[18] Lier, A. Bei der Berliner Polizei brennt die Uniform durch. https://www.bz-berlin.de/berlin/bei-der-berliner-polizei-brennt-die-uniform-durch.

[19] Krause, R.; Bell, E. Schutzkleidungsmaterial für Einsatzkräfte – Molotowcocktailschutz. https://www.ita.rwth-aachen.de/global/show_document.asp?id=aaaaaaaaaxtkqff (Accessed July 6, 2022).

[20] Technische Richtlinie (TR) Körperschu, 2009.

[21] DIN EN ISO 13937-2:2000-06, Textilien_- Weiterreißeigenschaften von textilen Flächengebilden_- Teil_2: Bestimmung der Weiterreißkraft mit dem Schenkel-Weiterreißversuch (einfacher Weiterreißversuch) (ISO_13937-2:2000); Deutsche Fassung EN_ISO_13937-2:2000; Beuth Verlag GmbH: Berlin.

[22] DIN EN ISO 9237:1995-12, Textilien_- Bestimmung der Luftdurchlässigkeit von textilen Flächengebilden (ISO_9237:1995); Deutsche Fassung EN_ISO_9237:1995; Beuth Verlag GmbH: Berlin.

AUTHORS:

RAHEL KRAUSE JUSTIN KUHN THOMAS GRIES