Technological advancement in Viscose fibre

By – Sushil Hada , TRADC, Birla Cellulose.

Clothing is the penultimate necessity for mankind after food & shelter. Majority of this clothing requirement is currently been fulfilled by cotton fibres. However, with the increasing consumer affluence, there has been a demand for better quality , high fashion and environment friendly products.

Recently, textile industry has noticed several breakthroughs in cellulosic and synthetic fibres backed by advanced technology and innovations. Viscose fibres have come across as a viable solution to cater to the clothing needs of the evolved customer.

According to the FIbre Organon, widely read publication on the fibre industry, global fibre consumption has grown at CAGR of 2.7% during 2007 -2013 where as viscose alone has grown at 8.4% CAGR. Which indicates that Viscose is becoming the preferred choice of evolved consumer. Birla Cellulose is the pioneer and leader in producing viscose fibre. Towards meeting the customer and consumer demand for better quality, & new application development , Birla Cellulose TRADC (Textile Research And Development Centre) has constantly innovated and advanced its offerings. Below article provides the details:

Advancement in regenerated fibre –

The major reason for growth of VSF (Viscose Staple Fibre) is investments in R&D in viscose fibre & its version (regenerated cellulose fibre) which has been complemented by technological upgradation and advancements in value chain as well. In yarn making unit, waste %, product yield/fresh packing and ability to produce variety yarn are focus areas and expecting raw material to support to achieve best in these areas. Similarly downstream processing expectation is in the same trend but looking beyond further in term of new application development, functional property advantage and uniqueness in product.

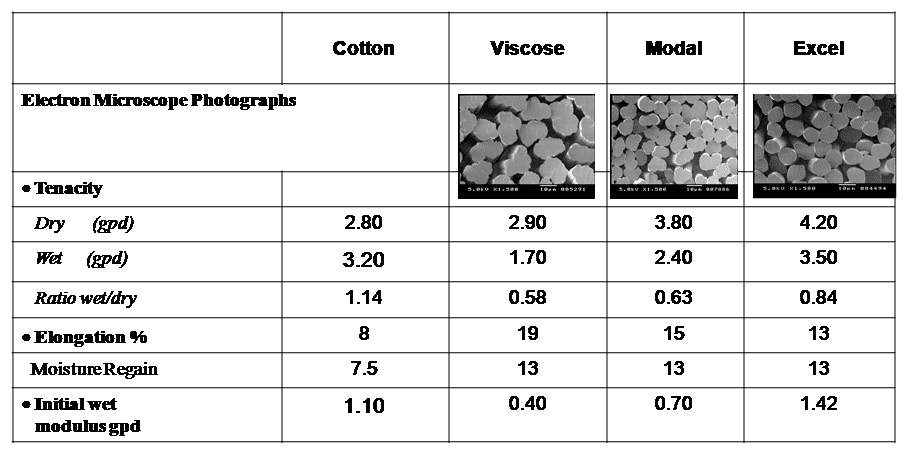

Following table depicts comparative properties of cellulose fibre-

Viscose is amongst the most viable cellulose fibre which compliments & supplements cotton and is also blend friendly with almost all fibres. Viscose is not only bio-degradable and eco-friendly but also the most pure form of cellulose.

Birla Cellulose, one of the pioneers in the fibre industry is leading this Viscose revolution. Birla Modal offers excellent fabric feel while Birla Excel is the green fibre with highest tenacity.

Advancement in generics of Manmade Cellulose fibre-

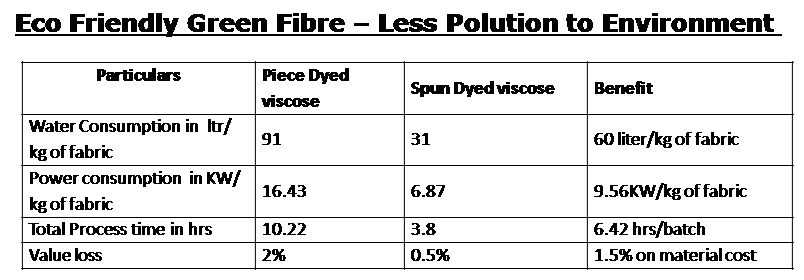

Birla Spunshades – are dope dyed viscose fibre where pigments dyes are impregnate into the dope prior to regeneration the fibre . Birla cellulose is the pioneer for this kind of fibre , having about 300 shades producing more than 300 KTPA . Birla Spunshades are not just known for their colour, which not just stays true and bright for years but is eco-friendly as well. Its available in 1.2D to 12 denier fineness & cut length 38 mm to 120 mm range.

Birla Spunshades are green fibres, which come with a minimum effluent discharge and significant cost reduction, benefiting the entire value chain.

Its accompanied with excellent all-fastness like washing, rubbing, perspiration etc. and is most suitable for uniform fabric , non woven, mélange shade development etc.

Below table indicating cost comparison of spun dyed VSF against piece dyeing

Birla Modal fibre – Usually referred as 2nd generation fibre, has been confirmed as high wet modulus (HMV) fibre which satisfies a minimum value of tenacity in the wet stage of 5% elongation, by the Bureau of International Standard Fibre Association (BISFA).

Bean shaped cross section, high wet modulus, and better fibre tenacity, allows Birla Modal fibre to render excellent softness , shade brilliancy and dimensional stability especially for ladies wear, night wear, undergarment and bed sheet for high class for a fashion product in 100% modal & blend with cotton etc. These superior physical properties make the fabric last longer with and enduring look and feel

Birla Excel fibre – With the generic name of Lyocell, this is the 3rd generation fibre produced from solvent spinning process. Solvent is used to dissolve pulp with almost negligible impact on environment. -High wet and dry strength, brilliant lusture & absorbency with a natural source, Birla Excel has it all

Birla Excel is most suitable for wash look effect product, home textile, ladies tops and is blend friendly with cotton, linen etc.

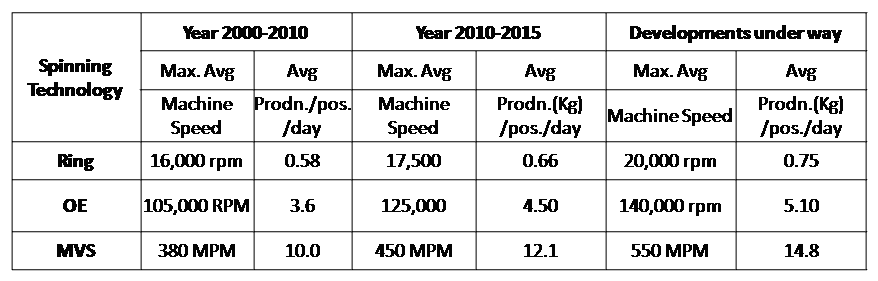

Advancement in yarn making technology –

Spinners always thrive to maximize production while keeping the costs low. Advancement in spinning technology such as open-end spin technology & air jet technology are getting popular amongst the spinners

Below table depicts the production pattern for different spin technology.

Consumer expectations of improved pilling and clean surface in knit fabric are addressed by the air jet technology

Advancement in viscose fabric processing

New dyeing technology support to reduced pilling formation

Air flow dyeing technique

Low ML ratio , reduced cost , less effluent, uniform dyeing specially for knit .

E –control dyeing technique

Very less water requirement, (10-15% of conventional) , less effluent, highly uniform dyeing technique

Keeping in mind these advancements in fibre spin technology and wet processing, there is lot of scope for textile entrepreneurs , fashion designers, fabricators, etc to enhance business by creating various innovative and new application based products for different segments in home textile, apparel, technical textile, medical textile etc.