India’s weaving industry is one of the largest in the world, with approximately 5 million weaving looms installed nationwide. However, despite its vast capacity, the industry struggles with low productivity and efficiency due to a heavy reliance on outdated machinery. To remain competitive in the global textile market, Indian weavers must transition towards modern weaving technologies such as shuttleless looms, including air-jet and rapier looms.

Current State of India’s Weaving Industry

- India houses about 2.3 million handlooms, 2.52 million power looms, and only 0.13 million shuttle-less looms.

- While India dominates the global handloom sector, its productivity per loom is significantly lower than that of mature textile economies like China, Indonesia, and Turkey.

- Approximately 45% of the world’s shuttle looms (power looms) are installed in India, yet the country lags in technological advancements and efficiency.

- The Surat textile industry alone contributes 65% of India’s total man-made textile production and operates 700,000 looms, yet less than 1% of these are shuttle-less looms.

The Need for Technological Upgradation

- India’s weaving sector is heavily dependent on obsolete power looms, leading to high labour costs, inconsistent fabric quality, and excessive energy consumption.

- The adoption of modern shuttle-less looms, including air-jet, rapier, and water-jet looms, is critical for improving productivity and fabric quality.

- Government support through schemes like TUFS (Technology Upgradation Fund Scheme) makes modernisation more accessible for weavers.

Comparison of Modern Weaving Technologies

|

Feature |

Air-Jet Loom |

Water-Jet Loom |

|

Energy Consumption |

Higher than water-jet but optimised for efficiency |

Lower than air-jet |

|

Water Consumption |

No water required |

Requires large amounts of water |

|

Environmental Impact |

Eco-friendly |

Contributes to water pollution |

|

Fabric Versatility |

Suitable for spun and filament yarns |

Limited to synthetic filaments |

|

Maintenance & Operating Cost |

Medium |

Low, but additional water treatment costs |

Why Choose Air-Jet Over Water-Jet Looms?

- Environmental Sustainability: Air-jet looms do not consume water, whereas water-jet looms require significant amounts, contributing to water shortages and pollution.

- Versatility: Air-jet looms can weave both spun and filament yarns, allowing a wider variety of fabrics.

- Higher Speed & Efficiency: Air-jet looms operate at speeds of up to 800 rpm, increasing fabric production.

- Reduced Regulatory Compliance: Water-jet looms require wastewater treatment facilities, whereas air-jet looms have minimal regulatory concerns.

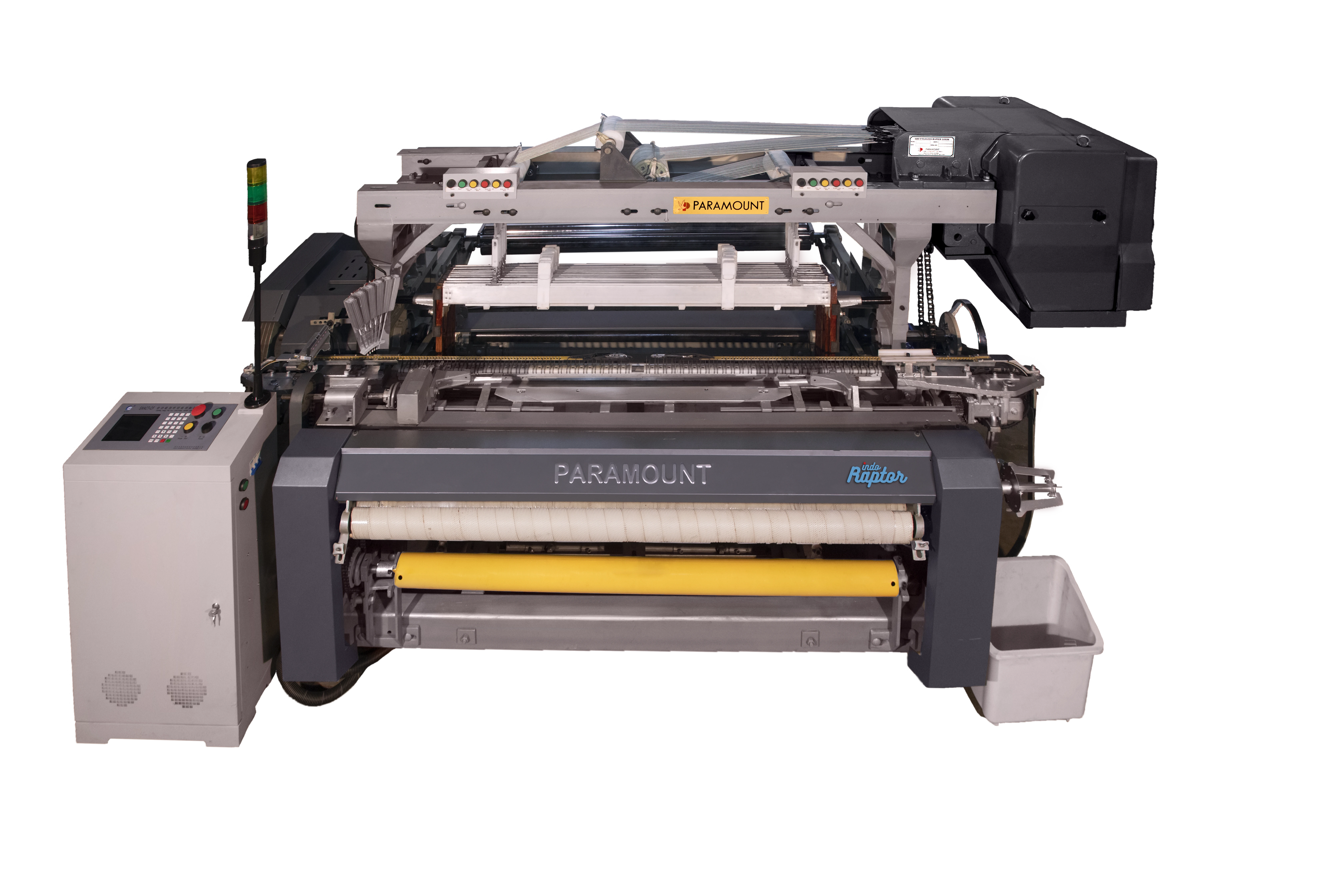

Rapier Looms: The Future of Value-Added Fabric Production

- Rapier looms provide the highest versatility, enabling the weaving of high-value fabrics such as brocades, Zari fabrics, and jacquard designs.

- Capable of handling multiple weft colours, making them ideal for fashion and home furnishing textiles.

- Lower investment cost than air-jet looms, making them a cost-effective option for small and medium-scale weavers.

Advantages of Adopting Shuttle-less Loom

- Increased Productivity – Shuttle-less looms are 3–5 times more productive than conventional power looms.

- Better Fabric Quality – Eliminates defects caused by mechanical wear in power looms.

- Lower Labor Costs – Requires fewer operators per machine, reducing overall production costs.

- Space Optimisation – More looms can be installed per unit area, increasing manufacturing efficiency.

- Access to Premium Markets – Modern fabrics produced with shuttle-less looms cater to global fashion and home textile brands.

- Faster Payback on Investment – With government subsidies and increased efficiency, most shuttle-less looms achieve ROI within 1.5 to 3 years.

Conclusion: The Way Forward

The Indian weaving industry stands at a crossroads. While traditional weaving practices remain a significant part of the sector, modernisation is essential to sustain long-term growth. Air-jet and rapier looms offer the best options for weavers looking to enhance efficiency, fabric quality, and market reach. With increasing global demand for high-quality textiles and the government’s push for technological adoption, investing in modern weaving technologies is the key to India’s future in the global textile industry.