AAS Tech is at the forefront of weaving innovation, driven by Swiss engineering principles and precision manufacturing. The company is committed to enhancing efficiency, durability, and cost-effectiveness in textile production while prioritising sustainability. With a deep understanding of industry challenges, AAS Tech develops high-performance weaving components that redefine productivity and reliability.

At the heart of AAS Tech’s innovations is Nirav Ashok Shah, a techpreneur, scientist, and visionary leader, along with the support of his parents, Ashok and Asha Shah. Their vision is to enhance productivity, minimise downtime, and establish new benchmarks in the weaving industry.

Engineering Excellence and Sustainability

AAS Tech’s advanced manufacturing processes set new industry standards, incorporating:

- Precision Engineering: Products developed using Swiss technology for unparalleled accuracy.

- Extended Product Lifespan: Healds and components come with a 3-year warranty.

- Sustainable Manufacturing: Operating India’s largest building-integrated vertical solar plant to minimise its carbon footprint.

Innovations in Heald Technology

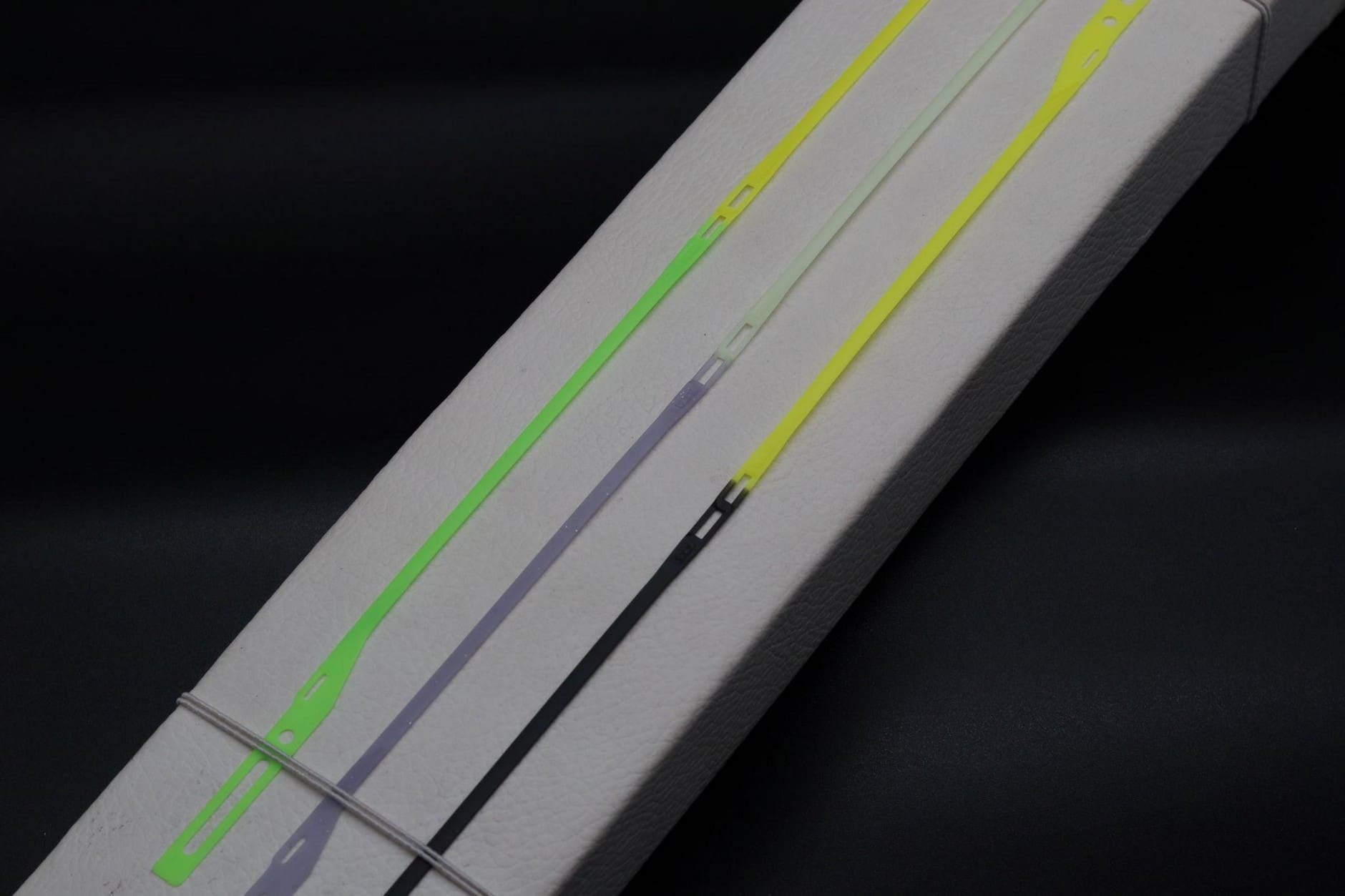

Version 3.0 Wire Healds: The thinnest and slimmest AAS healds yet, suitable for wider applications, including satin weaves. Key benefits include:

- Dual-Eye Configuration: Reduces material wastage by 40%.

- Optimised Visibility: A dual-color design enhances precision.

- Two-Material Composite: Boosts tensile strength and wear resistance.

- Reduced Downtime: Engineered for longevity.

Advanced Textile Components

AAS Tech expands beyond heald technology with specialised components:

- Advanced Tubes: Featuring a multi-coloured spiral design with Thread Detection Technology, increasing weaving accuracy by 25% and improving yarn control.

- High-Performance Leg Pins: Engineered with Shape Retention Technology to withstand extreme tension, ensuring superior thread fitment and enhanced fabric quality.

- Premium-Grade Springs: Crafted from superior SS304 and SS316 stainless steel for consistent elasticity, preventing iron oxide deposits and ensuring smoother operation.

S Flat Healds: A Revolutionary Design

AAS Tech’s S Flat Healds are the only flat-eye healds in the world, enhancing yarn guidance, reducing friction, and ensuring precise weaving movements.

Key Features & Advantages:

- Flat Eye Design: Provides an optimised entry and exit angle, reducing rubbing and ensuring superior yarn handling.

- S-Loop for Friction Control: Guides the yarn efficiently, preventing unnecessary movement and minimising rubbing.

- Elliptical Shape: Allows for the least resistance at the eye entry and exit points, ensuring smooth operation with minimal friction.

- Two-Material Composite Construction: Enhances durability, reduces wear, and improves overall weaving performance.

Commitment to Technological Advancement

AAS Tech believes in continuous evolution through research and development, empowering manufacturers with tools that enhance productivity, optimise costs, and push the boundaries of textile engineering.

Why Choose AAS Tech?

- Swiss-engineered precision with in-house manufacturing

- Proven track record of increasing weaving efficiency and reducing downtime

- Commitment to sustainability and eco-friendly production processes

- A dedicated R&D team focused on textile innovation

- Trusted by leading weaving units and textile manufacturers worldwide

For inquiries, contact +91 87995 99296, visit www.healds.tech, or get in touch with the AAS Tech team.