ABSTRACT

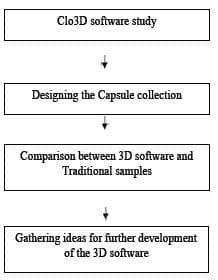

The purpose of this paper is to justify the benefit of using 3D software over traditional sampling method as the traditional method of sample making requires to create number of physical samples without which the bulk production cannot take place. However, creating number of physical samples requires time, manpower and raw materials that adds up to the production costing as well as impact the environment negatively. As a result, to reduce the impact on environment and save costing, digital 3D design software’s can be used.

INTRODUCTION

Clothing is an integral part of human society, and fashion is one of its popular aesthetic expressions. With the development of industrialization, people started adhering to new innovations such as sewing machines, and mass production of clothing started. Manufacturing of clothing involves a number of stages like product design, sampling, bulk sewing, quality control, etc and during each stage, a considerable amount of waste is generated. Also, at various stage of sample development, factories must develop different types of samples such as fit sample, size sample, proto samples etc. Creating these physical samples costs a lot to the garment factory. This sampling is frequently used to create mockups which are then fitted and photographed before being discarded. This samples are then burnt and discard into the landfill. The traditional method of sampling requires considerable amount of time and resources that adds to the negative impact on the environment, due to the different stages of sampling. The environmental impact of our garments is something that most people don’t think about. Textile manufacturing necessitates large quantities of chemicals, water, energy, and other natural resources. Solving this global waste crisis is a crucial and the present time is in dire need of it. The development of technology and increasing prevalence of digital software has made its way into the fashion industry. There are different softwares such as CLO3D, Optitex, Marvelous designer, etc that can be used to determine silhouette, proportion, design elements and colours.

This will bring sustainability into practice in the area of garment industry by saving natural resources and reducing carbon footprint.

REVIEW OF LITERATURE

CLO3D system realizes virtual fitting, including threedimensional body modeling, parametric punching, three-dimensional virtual sewing fitting, fabric texture attribute setting, and dynamic display, which realizes the design and realization of display. The clothing deformation algorithm based on human input posture is used to deform the clothing model, which presents the physical characteristics of virtual clothing more truly. The position of human joints is obtained by feature extraction technology, and the

scaling ratio of the virtual clothes is calculated so that the virtual clothes are closely combined with the real-life image. Compared with similar virtual fitting systems in the industry, the information processing process of this system is more intelligent, the interaction is more natural, and the fitting efefct is more realistic. (Li. H, et al, 2022)

In order to study the software, the researcher took up a course to learn the software from the website www.learn3dfashion.com. This was an intensive course for serious fashion/textile designers, professionals, and illustrators to get personalized and detailed learning from zero to advance. This was an online course where the leaner can get

In order to study the software, the researcher took up a course to learn the software from the website www.learn3dfashion.com. This was an intensive course for serious fashion/textile designers, professionals, and illustrators to get personalized and detailed learning from zero to advance. This was an online course where the leaner can get

knowledge of the software at their own pace. It was two months course that consisted of recorded videos and weekly live classes.

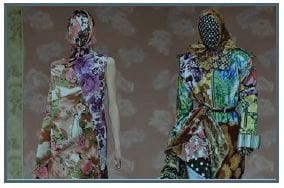

For the study total six garment samples were created. Three samples were created using the clo3D software and three samples were created using the traditional sampling method. From these three, one sample was graded using the software and one sample was given to the factory for manual grading. The researcher wanted to test different material types that includes printed and plain fabric as well as wanted to test the efficiency of grading through clo3d software and hence total six samples were selected to test three of each by traditional sampling method and using clo3D.

For the study total six garment samples were created. Three samples were created using the clo3D software and three samples were created using the traditional sampling method. From these three, one sample was graded using the software and one sample was given to the factory for manual grading. The researcher wanted to test different material types that includes printed and plain fabric as well as wanted to test the efficiency of grading through clo3d software and hence total six samples were selected to test three of each by traditional sampling method and using clo3D.

The 3D design course undertaken by the researcher got completed within the span of two months. Certificate of completion was also felicitated by the course instructor at the end of the course. All the topics within the syllabus mentioned in the previous chapter was covered and precisely completed. The study gave an insight an in-depth knowledge about the software and features that could be proven beneficial within the fashion industry. Any changes to 2D patterns, colours, textures, and finishing details are immediately reproduced, allowing the designer to assess changes in real time. The software allows to improve design quality by assessing silhouette and fit earlier in the development phase, giving samples more time to be refined before finalization. CLO can properly simulate drape-sensitive fabrics with diverse material qualities, such as lightweight wovens and jerseys.

RESULT AND DISCUSSION

The sample was stitched in factory based in Mahim, Mumbai. It took two to three weeks of time to create paper pattern, grading and stitching of six samples. From six samples, three samples were creating using traditional sampling method where the paper pattern and grading was done by the factory manually. 2D pattern and graded pattern generated through clo3d was also given for creating other three samples. The factory was also given a copy of techpack created on illustrator and through closet. From these two, the tech pack created using closet was more convenient and understandable as per the factory coordinators response. To create the samples, it was asked to the factory about the fabric consumption and requirement to follow traditional method process. The measurement detailed through CLO3D and manual measurement was very approximate and close enough and hence the garment result of both the samples was approximately same.

CONCLUSION

This paper aimed to compare and justify the benefits of using 3D software over traditional sampling method to leverage sustainability. Such comparison

was carried out by creating a collection using 3D software and using traditional sampling method. The analysis was done based on the survey conducted and through participant observation. The result indicates that adding 3D software as a tool to create

virtual garment gives accurate measurements that saves the raw material and time to create real life sample. Further findings shows that it is a widely accepting software because of its features and has the scope to create a new job opportunity for designers that can be considered as one of its kind to promote sustainable practice in the fashion industry.

This paper focused on solving the problem of garment waste generated at the stage of sampling making. To reduce the negative effects of production on the environment, brands must consider alternatives to traditional sampling methods. Making modifications to a sample used to require restarting the production process, but doing so with 3D sampling is significantly easier and give similar result. Using 3D digital software such as CLO3D, Optitex, Marvelous Designer can be used to solve the stated problem and leverage sustainability.

REFERENCES

Bibliography

1] Cline, E. L. (2019). The conscious closet: The revolutionary guide to looking good while doing good. Plume, an imprint of Penguin Random House LLC. ISBN-10 : 1524744301

2] Mike Easey (2009), Fashion marketing planning, 3rd ed. West Sussex, UK: John Wiley and Sons ltd. ISBN 9781405139533 pg. 21-28

3] Tony.H (2001): Reconstructing the challenge of consumer complexity: 1st ed : Oxford UK:E liseier ltd. ISBN-139780750668972 pg no. 54-56

Webliography

1] Almond, K. (2010, January 1). [PDF] insufficient allure: The luxurious art and cost of creative pattern cutting: Semantic scholar. researchgate. net. Retrieved January 18, 2022, from https://www.semanticscholar.org/paper/Insufficientallure% 3A-the-luxurious-art-and-cost-of- Almond/ a0d09d450cb0f7a474bda9c598f3f18b8c55f80e

2] Bae, S.-J., & Jung, J.-W. (2013). A comparative analysis of street fashion colors between Beijing and Seoul: The case of summer 2012*. Journal of Distribution Science, 11(11), 13–18. https://doi. org/10.13106/jds.2013.vol11.no11.13.

3] Boldt1, R., & Carvalho1, M. (2018, December 1). IOPscience. IOP Conference Series: Materials Science and Engineering. Retrieved February 17, 2022, from https://iopscience.iop.org/ article/10.1088/1757-899X/460/1/012040

4] Carrico, M. R. (2022, January 23). Grading zero-waste garments. Sustainability in Fashion -. Retrieved January 17, 2022, from https://www. academia.edu/69277533/Grading_zero_waste_ garments

5] Chen, T., Yang, E. K., & Lee, Y. (2021). Development of virtual upcycling fashion design based on 3-dimensional digital clothing technology. The Research Journal of the Costume Culture,29(3), 374–387. https://doi.org/10.29049/ rjcc.2021.29.3.374

6] Chen, T., Yang, E. K., & Lee, Y. (2021). Development of virtual upcycling fashion design based on 3-dimensional digital clothing technology. The Research Journal of the Costume Culture, 29(3), 374–387. https://doi.org/10.29049/ rjcc.2021.29.3.374

7] Chittaro, L., & Corvaglia, D. (2003). 3D virtual clothing. Proceeding of the Eighth International Conference on 3D Web Technology – Web3D ‘03. https://doi.org/10.1145/636593.636605

8] Cichocka, A., Bruniaux, P., & Frydrych, I. (2014, January 1). Figure 3 from 3D garment modelling – creation of a virtual mannequin of the human body: Semantic scholar. researchgate. net. Retrieved February 21, 2022, from https:// www.semanticscholar.org/paper/3D- Garment-Modelling-Creation-of-a-Virtual-of-the-Cichockaia10278800a11b0af40d2a4bf690131892f7da857/ figure/2

9] CLO3D-based 3D virtual fitting technology of down jacket … (n.d.). Retrieved January 26, 2022, from https://www.researchgate.net/publication/358724242_CLO3D- Based_3D_ Virtual_Fitting_Technology_of_Down_Jacket_and_

Simulation_Research_on_Dyna mic_Effect_of_Cloth

10] Cobb, K. (2020). Comparing physical to virtual: Fit and appearance of multi-layered cultural garments. Journal of Textile Engineering & Fashion Technology, 6(2). https://doi.org/10.15406/ jteft.2020.06.00226

11] Connell, K. Y., & Kozar, J. M. (2014). Environmentally sustainable clothing consumption: Knowledge, attitudes, and behavior. Textile Science and Clothing Technology, 41–61. https://doi.org/10.1007/978-981-287-110-7_2

12] Dai, L., & Zhou, J. (2009). The application of 3D digital technology to Fashion Design. Asian Social Science, 4(6). https://doi.org/10.5539/ass. 13] Data Management Planning. (2017).The Data Book, 67–81. https://doi. org/10.1201/9781315151694-4

14] The development of design ideas in the early apparel design process: A … tandfonline. (n.d.). Retrieved January 19, 2022, from https://www.

tandfonline.com/doi/pdf/10.1080/17543266.2015. 1026411

15] Digital 3D design as a tool for augmenting zerowaste … researchgate.net. (n.d.). Retrieved February 29, 2022, from https://iom3.tandfonline.com/doi/pd f/10.1080/17543266.2020.1737248 E, P., & N, B. (2017). 3D Virtual Prototyping traces new avenues for fashion design and product development: A qualitative study. Journal of Textile Science & Engineering, 07(02). https://doi.org/10.4172/2165-

8064.1000297

16] E, P., & N, B. (2017). 3D Virtual Prototyping traces new avenues for fashion design and product development: A qualitative study. Journal of Textile Science & Engineering, 07(02). https://doi. org/10.4172/2165-8064.1000297

17] Gardetti, M. Á. (2016). Sustainability in the textile and Fashion Industries: Animal Ethics and welfare. Textile Science and Clothing Technology, 47–73. https://doi.org/10.1007/978-981-10- 2182-4_2

18] Guidelines for Engineering Design for Process Safety, 2nd edition (2012). (2012). Process Safety Progress, 31(3), 320–321. https://doi.org/10.1002/ prs.11501