The newest SAVIO automatic winder Proxima Smartconer® will be presented soon to the Indian market at INDIA ITME exhibition, taking place in New Delhi from 2022 Dec. 8-13th.

Italy, October 2022 – Savio is launching the newest SAVIO automatic winder Proxima Smartconer® in a roadmap that will start in India in Dec. 2022 and will land in ITMA MILAN in June 2023.

Proxima Smartconer® is the result of the commitment of Savio R&D team in the last 3 years. It testifies Savio’s dedication to innovation technology and strong partnerships across the industry.

TEXTILE SOLUTIONS TOGETHER

Savio has always acted as technological leader and innovative player in the textile machinery industry. Innovation technology and customer centricity are Savio drivers for developing new products. Our innovations aim to impact on the customer’s value chain; we want to be together as partners and offer not only innovative products, but also our expertise and solutions able to satisfy customer needs. TEXTILE SOLUTIONS TOGETHER is our philosophy and summarizes our customer-oriented approach.

NEXT DESTINATION: PROXIMA Smartconer

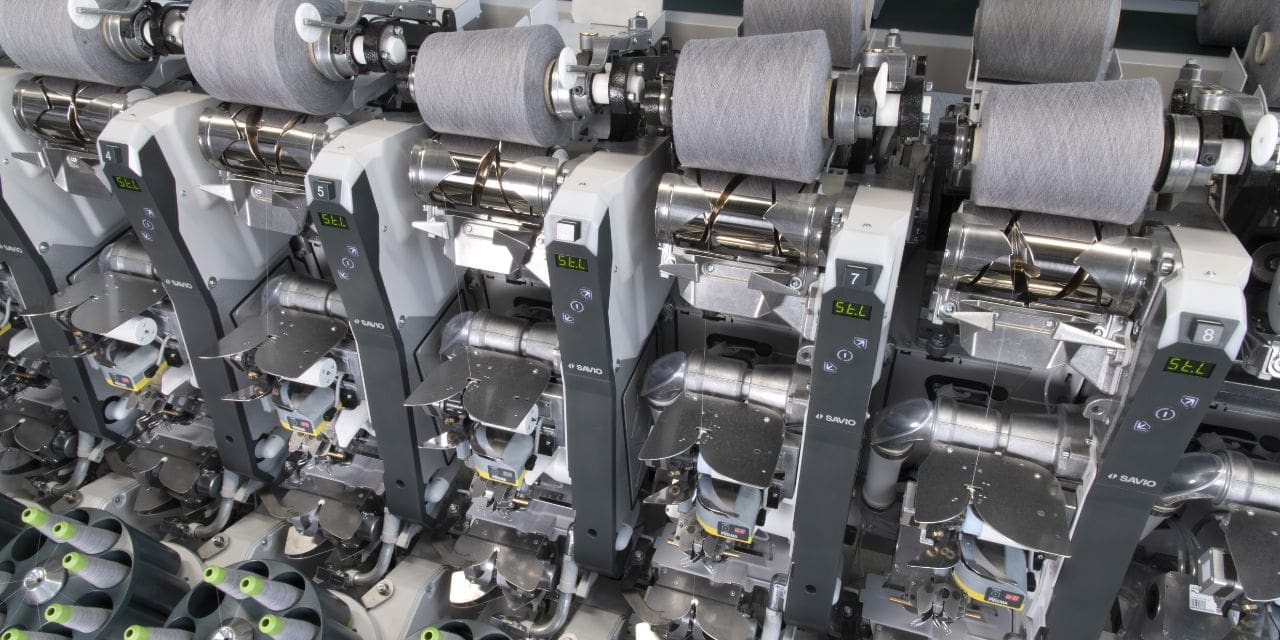

The new winding machine Proxima Smartconer is setting the benchmark in Savio automatic winding.

We have combined the name Proxima with Smartconer: it stands for a high-tech winding machine, capable of perfectly adapting to demands of Connectivity, Industry 4.0 and Industrial Internet of Things.

Thanks to the innovations, spinners will get a machine featuring high-tech capabilities, thanks to a design with a strong focus on the main benefits for customer’s competitive advantage: high productivity, low energy consumption, premium yarn quality, automation, and data connectivity.

Proxima Smartconer has been designed with the foremost attention to the customer’s needs in the optimal utilization of a winding machine.

Investing in equipment that enables to work faster and reduces manual and repetitive tasks, can increase both efficiencies and overall productivity. The same applies to a new equipment that does more of what is needed, faster, safer, with better quality but with less waste, less maintenance and less resource usage.

The team at Savio is steadfast to provide textile solutions for spinning business growth with unsurpassed customer service, response time, and technical expertise.

THE MAIN BENEFITS OF PROXIMA SMARTCONER® FOR COMPETITIVE VALUE:

- HIGH PRODUCTIVITY: Thanks to the new Smart Booster, to a shorter bobbin change cycle, to a faster splicing

- LOW ENERGY CONSUMPTION: through the usage of the latest and most efficient self-regulating independent motors and frequency inverters.

- PREMIUM PACKAGE QUALITY: Thanks to the new splicer and new tension

- USER EXPERIENCE: Easy use and settings thanks to the new HMI – Human Machine

- AUTOMATION: Efficient bobbin flow in the automated models.

- SERVICE FRIENDLY: Easy maintenance and accessibility to components.

- CONNECTIVITY: Smartconer® means a winder with many Smart functions, for a more connected, increasingly efficient, and flexible machine. Smart monitoring of the winding process is possible thanks to the IIoT (Industrial Internet of Things) digital solutions.

BOOST THE PRODUCTIVITY OF YOUR BUSINESS

Investing in new equipment as Proxima Smartconer, as well as in Savio’s leading-edge technologies, enables spinners to be more agile and responsive as business needs change. It’s important to note that those gains in productivity and efficiencies while producing fault free packages, can generate significant cost savings.

You can benefit from huge returns in terms of productivity with Proxima Smartconer®.

The high productivity of the machine is obtained thanks to multiple factors that help optimizing the performances. More kgs of yarn produced, high productivity thanks to:

- Smart Booster, new device for bobbin unwinding that increases the winding speed and reduces yarn tension

- Fast bobbin change cycle plus 1 extra bobbin in

- Less power consumed per Kg of yarn produced

- New yarn tensioner and shorter splicing

USER-FRIENDLY HMI TO FACE THE PROBLEM OF STAFF USAGE

Savio goal was to create an easy and intuitive HMI that gives back to those who use it the same familiarity and simplicity they experience when handling a smartphone. From this point of view, the HMI has been completely revised to facilitate an intuitive approach.

An HMI (human-machine interface) is a device or software that allows an operator to be able to “communicate” with a machine or a production plant. In fact, it converts a huge amount of complex data into information that any operator can understand. Even more so if this type of interface, as in the specific case, makes use of graphic elements such as icons: this further helps the less experienced operator to move easily around the system. An important aspect concerns the declination in a 4.0 key. There is, in fact, the possibility of accessing the system remotely, with significant advantages also in terms of maintenance. In fact, timely contextual information is provided, with remote accessibility for technical assistance and the possibility of remote control of the interface on mobile devices and PCs for assistance and maintenance also by the customer. And the 4.0 predisposition can be interfaced with management systems.

CUSTOMER SERVICE![]()

A user-friendly machine allows spinners to respond quickly to changes or manufacturing challenges, to increase the ease of use and management of the machine, thereby improving efficiency and reducing machinery downtimes. PROXIMA Smartconer has been designed to be easy to use, both for the setting of machine functions and for maintenance.

The newly designed user-friendly interface with touch screen functionality allows to easily setup working parameters. The interface of PROXIMA Smartconer® allows to monitor machine even remotely and to display dashboards, with the aim of simplifying processes and factory operations. Operators can also use machine PC interface to quickly display KPIs and manage alarms. The ability to make the necessary adjustments from the screen makes this process quick and easy.