Transforming common processes – for greater sustainability and strong collaboration, says DMIx website. DMIxlooks at new digital dimensions of global interaction and exchange between brands and suppliers in the fashion and lifestyle industry. The unique DMIx Software-as-Service (SaaS) solution covers all relevant areas – from digital product development to production in a unique colour and appearance-controlled environment.

DMIx enables all stakeholders to interact based on standardised digital colours, raw materials, products, human avatars and real-time master data, including design and PLM solutions.DMIx supports the integrated supply chain from inspiration to mass production of raw materials and fully covers all 3D design development requirements including digital twins.

GerdWillschütz, COO of DMIx by Color Digital and Tal Shogol, CEO of Made2flow reply to some questions from the Textile Value Chainabout DMIx. Excerpts:

Q: What is the concept of DMIx?

A: It is our mission to digitally transform the supply chain to create a better industry: better for brands, suppliers, and the planet.

DMIx is a unique ecosystem offering seamless digital interaction between brands and suppliers in the fashion and lifestyle supply chain. The DMIx platform enables all stakeholders to transform from physical to virtual collection development with real-time digital exchange of designs, using technology that reproduces colours and textures as close to reality as possible. DMIx is based on standardized digital colours, raw materials, products, human avatars, and real-time master data, communicating with design and PLM solutions. Not only does this reduce costs and time for our customers, it also minimises environmental footprint by controlling lab dipping and bulk production, thus reducing the vast number of samples and prototypes traditionally used.

Our solutions encourage full transparency, openness, and collaboration within our unique ecosystem, enabling our customers to forge new relationships between all stakeholders along their extended value chains.

Q: The unique DMIx Software-as-Service (SaaS) offers solutions in which areas?

The innovative Software-as-a-Service solution create new digitized levels of interaction and collaboration between brands and suppliers. Based on the DMIx Digital Twin Technology used within DMIx, we offer:

▪ Colour measurement, colour archiving and cross referencing.

▪ Colour development between brands, T1 and T2 suppliers including tools for lab dipping, bulk control, and digital swatch exchange (cross referencing)

▪ Print design and quality control tools.

▪ 3D library with all tools needed to digitize, analyse, and adjust PRB texture for virtualization.

▪ Full working ecosystem for exchange of master data

▪ Rendering workflow including high end human avatars for photorealistic renderings in exchange with all relevant 3D CAD solutions (CLO, BRowzwear, etc.)

Q: How does the DMIx support the integrated supply chain and contribute towards sustainability?

- Based on high quality digital assets, and with our Digital Twin Technology, we enable brands to validate models without the vast number of samples, prototypes and shipments traditionally used, thus reducing their environmental footprint.

- Our aim is to eliminate physical sampling to the highest degree possible.

- Our open API architecture allows the flow of standardized data for different processes and systems like PLM or ERP.

- How do 3D materials and 3D objects help the customers?

- By standardizing the 3D workflow on material and object level, we enable our clients to build up libraries full of assets, including relevant master data that can be exchanged with their various clients so they can develop a fully working digital pipeline.

Q: How does the human avatar help the customers in getting a real-time experience?

A: The DMIx human avatar is the peak of 3D development: it’s human representation.When working in virtualization where human characters are involved, which is highly relevant to the fashion and lifestyle related industries, the avatar needs to be as realistic as possible.

DMIx offers, for the first time, a standardised high-end rendering solution. Customers can improve their workflow with avatars representing a collection in a fully digital environment.

In test situations with customers, they were not able to tell which images were real photos and which were a full rendering.

Q: Which are some of your partner companies or your clientele?

A: DMIx works with fashion brands including HUGO BOSS, PVH, Marzotto, Amann and Mammut. We also interact with soft- or hardware solutions that are used by our clients. In the 3D area there are CLO, Vidya, Browzwear to name a few. DMIx can also directly connect to hardware from Datacolor or Xrite and is a fully licensed reseller for the digital Pantone Color libraries. We also support various scanning devices for materials including Vizoo.

Q: What is the concept behind ‘ Made2Flow’?

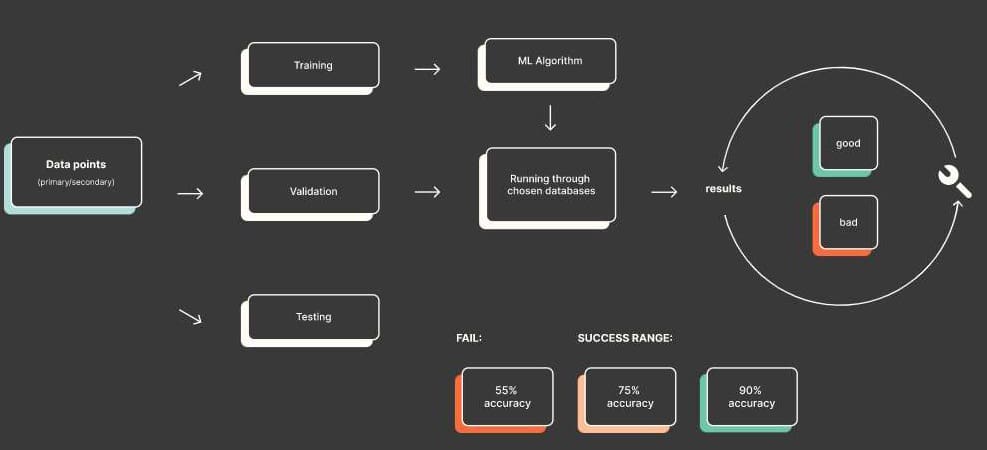

A: Made2Flow is a data company specializing in data gathering & data validation across supply chains in the fashion industry for the purpose of environmental impact measurement. Its goal is to enable fashion brands to bridge the gap between supply chain expertise & environmental science to accelerate impact reduction.

Made2flow was formed by an experienced team of fashion supply chain experts, environmental specialists & tech wizards with the understanding that impact measurement solutions need to be seamless, scalable, and most importantly transparent.

Q:How is Made2Flow different from most of the other brands and how is it a leading name in the industry?

A: Made2flow has developed proprietary technology & different automations ranging from data gathering across tiers 1-4 through data validation and impact measurement at scale to be able to personalize calculations and ensure credible measurement results. Results can be aggregated for internal reporting and ensuring targets are met in time or as a variety of consumer facing solutions. Furthermore, Made2flow offers complete data transparency allowing brands to overcome public scrutiny and share results with confidence.

Over the last 3 years, Made2Flow has measured thousands of supply chains globally (tiers 1-4), serving leading fashion corporates and brands and developed multiple partnerships with data providers across the supply chain, exactly like this exciting collaboration with DMIx to streamline granular, environmental data flow regarding fabrics, trims and more that brands are so eager to have.

We are the only digital ecosystem that offers seamless digital interaction in all relevant areas in the fashion and lifestyle industry. By connecting and interacting with all stakeholders within the supply chain, we generate savings in cost, time and the environmental.

Q: What are your plans for expansion? Or going global?

A: We are already working on a global scale with more than 500 connected suppliers and brands. We are building service centres or partner with existing player to cover all needs in terms of training and service. In general, the solution is easy to use. Furthermore, we take great care that DMIx is well connected to the local internet infrastructure across the globe, by setting up strategic access points in various regions.

Q: Do you have any specific strategy for expansion in countries like Bangladesh or Vietnam?

A: We see a lot of potential and huge willingness to use digital tools in these countries. I think there we can find close contact between people who not only design and simulate with digital tools but also connect to the needs of industrial production – which is exactly what we have to offer. There are some major things in the development pipeline, but it is too early to speak about this. Especially in material scanning we believe there is still room for improvement for the never-ending desire for perfection.

AUTHORS:

GERD WILLSCHUTZ – COO OF DMIX BY COLOR DIGITAL

GERD WILLSCHUTZ – COO OF DMIX BY COLOR DIGITAL

TAL SHOGOL- CEO OF MADE2FLOW