This study is about the effect of some mechanical properties on PC-Cotton fabric produced by keeping cotton as constant warp & having cotton and PC blend in weft with different pick ratio. It is observed that fabric having PC: cotton 1:1 ratio in weft shows highest value in mechanical properties among all. It can be said that in fabric properties, anatomical difference has terrific part.

Keywords: Polyester Cotton blend, Fabric, Mechanical property.

Introduction

In Indian market, PC blends have obtained substantial vogue. Remarkable cost limiting by reduction of polyester content in PC fabrics is achievable without affecting consumer interest.1 Fiber type, crimp, blend type, contraction, yarn structure etc affects fabric frictional properties.2 In polyester-viscose blend, by increasing polyester content breaking strength and extensibility can be increased.3

Fabric breaking strength is also known as tearing strength. It point out as the supreme tensile force when material is extended to smash. And it is used to assess the potential of fabric to withstand to tensile harm.

Elongation at break or fracture strain, it explains the between changed length and initial length after breakage of the test specimen. Force is applied to material until it breaks.

Abrasion resistance of fabric can be explained as, the potential of fabric to hold out against surface wear created by rubbing touch with another specimen.

Methods and Materials

Materials: Fabric is produced by using Polyester cotton blend in weft having blend ratio 65:35, of 34s count in which polyester fiber has 1.2 denier and, 38 mm staple fiber where as cotton is having micronaire value 4. Yarn has blend ratio polyester to cotton 65:35. And cotton in warp.

Total 5 samples were made with cotton in warp, and cotton and PC in weft at different pick ratio and plain as weave. In sequence sample 1 has cotton : PC ratio1:1, sample 2 is made by taking cotton both in warp as well as in weft, sample 3 has cotton in warp and PC in weft, sample 4 has cotton : PC ratio 1:2 and sample 5 has cotton : PC ratio 2:1.

Methods: Testing is done by standard test methods and at 27º C and 67% RH.

Total 3 mechanical tests were examined. Breaking strength and elongation at break were examined by ASTM D: 5035 and abrasion resistance was examined by ASTM D 3884.

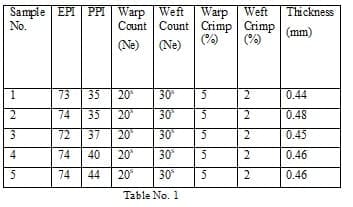

Basic data of samples are given in table no. 1

Results

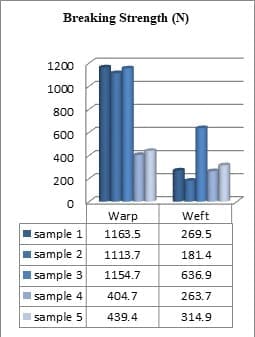

BREKING STRENGTH: Sample 1 shows greatest breaking strength warp wise, whereas sample 4 shows lowest breaking strength whereas in weft sample 3 has highest value and sample 2 has lowest.

Chart No. 1 shows complete data of breaking strength.

Chart No. 1

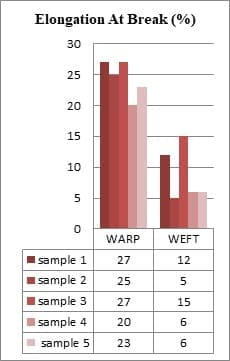

ELONGATION AT BREAK: Sample 1 and 3 has same highest value of elongation at break in warp wise whereas sample 4 has least value. And in weft wise sample 3 has highest value and sample 4 and 5 has same least value.

Chart No. 2 shows complete data of elongation at break.

Chart No. 2

ABRASION RESISTANCE: Sample 1, 2, & 3 has same values that are highest too and sample 4 has least value among all. Data is given in following table.

Table No. 2

Conclusion

Fabric having cotton as warp and PC as weft shows better values of mechanical properties among others. And fabric having pick ratio 1:2 and 2:1 has poor performance in relatively all properties.

References

- G V Sarma, Surinder Singh, B C Verma & Anu Sakhuja, “Influence of Blend Composition and Weave on Some Mechanical Properties of Polyester-Cotton Blends”, Indian Journal of Textile Research, 5, December 1980, 114-121.

- A Das, V K Kothari & V Nagaraju, “Frictional Characteristic of Woven Suiting & Shirting Fabrics”, Indian Journal of Fiber & Textile Research, 32, September 2007, 337-343.

- G S Bhargava & R K Yadav, “Effect of Blend Composition & Fabric Set on Some Characteristics of Polyester-Viscose Fabrics”, Indian Journal of Textile Research, Indian Journal of Textile Research, 8, December 1983, 115-120.

Shuchi Shrivastava# , Tanveer Malik*

#M.Tech Student, Shri Vaishnav Institute of Textile Technology, SVVV, Indore

*Assistant Professor, Shri Vaishnav Institute of Textile Technology, SVVV Indore