Ajay Joshi, Tanveer Malik- Faculties

Kajol Jain- Student

Shri Vaishnav Vidyapeeth Vishwavidyalaya, Indore

Abstract

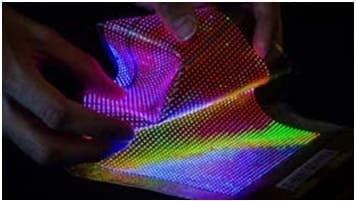

Textiles have been at the heart of human technological progress for thousands of years, with textile developments closely tied to key inventions that have shaped societies. The relatively recent invention of electronic textiles is set to push boundaries again and has already opened the potential for garments relevant to defense, sports, medicine, and health monitoring. The literature shows that electronics can be integrated into textiles, where integration is achieved by either attaching the electronics onto the surface of a textile, adding electronics at the textile manufacturing stage, or incorporating electronics at the yarn stage. Methods of integration can have an influence on the textile’s properties such as the drapability of the textile.

Introduction

The development of textiles reflects the civilization of humans to a certain extent: A variety of leaves were reconnected by our ancestors to form the early models of textiles; natural materials such as silk and cotton were then woven into real textiles that were warmer and more comfortable; nylon and Kevlar, gradually appeared and greatly enhanced our lives over the last century; textiles are now expected to exhibit additional functionalities besides making people warm and comfortable. It is promising or required to make electronic devices into textiles for a more efficient use of electricity in many fields, such as displays and sensing. The fact that electricity dominates our life and is everywhere means that the development of smart electronic textiles is important and has possible practical applications.

‘Electronic textiles also known as smart garments are fabrics that enable digital components such as a battery and a light (including small computers), and electronics to be embedded in them’. The first examples of the modern electronic wearable technologies with considerable sensing and computational abilities emerged in the form of smart phones, smart watches, and smart eyeglasses. In these devices, the electronic functionalities are built into standard and rigid daily life objects already in use.

Electricity-Generating Textiles

Electronic devices are all powered by electricity. We begin this with textiles that can convert other energy source into electric energy. The most accessible forms of energy from the environment include light as well as thermal and mechanical energy. These can be converted into electric energy through photovoltaic, thermoelectric, and piezoelectric effects.

Conversion from light energy

The photovoltaic effect generates electricity in a device upon exposure to light. The electrons in the valence band absorb light energy, become excited, and jump to the conduction band to become free. The excited electrons diffuse to reach a junction where they are transported into different materials by a built-in potential to produce electric currents. Solar cells generally demonstrate the above process. Although a variety of solar cells are planar, third-generation solar cells but typically, the third-generation solar cells are first fabricated onto fibre substrates, and the fibre-shaped solar cells are then woven into photovoltaic textiles.

The sub classifications are:

- Fibre shaped solar cells

- Textile shaped solar cells

Conversion from mechanical energy

The piezoelectric effect has mostly been investigated regarding converting mechanical energy into electric energy. Of decisive importance for the piezoelectric effect is the polarization change in the piezoelectric material under a mechanical stress. The change in polarization appears as a variation in the surface charge density.

They are simply constructed on piezoelectric materials and positive/negative electrodes. Studies showed that, more commonly, alternating current/voltage out- puts are obtained in a cycle consisting of exerting and releasing stress. In 2008, a fibre-shaped piezoelectric Nano generator (PENG) gave a direct output. Thereafter, fibre and textile-shaped PENGs started to attract increasing attention.

The sub classifications are:

- Fibre shaped piezoelectric generators

- Textile shaped piezoelectric generators

Conversion from thermal energy

The thermoelectric effect is generally used to convert thermal energy into electric energy. The most explored thermoelectric devices convert temperature gradients (dT/dx) to electric energy through the See Beck effect, while the less explored pyroelectric effect generates electricity from temperature fluctuations (dT/dt) as result of thermal diffusion. A high temperature gradient or fluctuation is preferred, and thus thermoelectric devices are rarely used in wearable electronics. On the other hand, it would be adventitious if the heat from the human body could be used to generate electricity effectively.

The sub classifications are:

- Thermoelectricity

- Pyroelectricity

Textiles for Electricity Storage

Besides generating electricity, it is also important to store electricity for effective use. Thus, energy-storage textiles are also required for wearable electronics. Lithiumion batteries and super capacitors represent two main formats for storing electricity as a result of their high energy and high-power densities, respectively. In recent years, both have been incorporated into energystorage textiles.

Lithiumion batteries

A lithium-ion battery consists of a negative electrode, a positive electrode, and an electrolyte. For a typical working process, lithium ions move from the negative electrode to the positive electrode during discharging and in the reverse direction during charging. The electrolyte allows ionic transport between the negative and positive electrodes. Both electrodes are composed of active material, conductive additive, and binder. Active materials in the positive electrode typically include lithium salts, such as LiCoO2, LiMn2O4 and LiFePO4. Active materials in the negative electrode are classified into carbonaceous materials, metals/alloys, and oxides/sulfides (e.g.,Li4Ti5O12).The binder is made of thermoplastic polymers, and conductive additives are made of carbonaceous materials such as carbon black, CNTs, and graphene. To prepare an electrode, slurry of active material, binder, and conductive additive is formed first and then cast onto a current collector (usually Cu for the negative electrode and Al for the positive electrode).

Lithiumion batteries are classified as:

- Fiber shaped lithiumion batteries

- Textile shaped lithiumion batteries

Super capacitors

In contrast to batteries with high energy densities, super capacitors have been widely investigated regarding high power densities. Like lithium-ion batteries, super capacitors have structure with the electrolyte sandwiched between two electrodes. According to energy storage, they are categorized as double layer capacitor and pseudo capacitor. An electrostatic double layer capacitor is typically made from carbon electrodes and realises charge separation at the interface between the electrode and electrolyte. A pseudo capacitor is generally fabricated from metal oxide or conducting polymer electrodes and uses redox reactions to store energy.

Super capacitors are classified as:

- Fibre shaped super capacitors

- Textile shaped super capacitors

Multifunctional Electronic Textiles

Electronic textiles with a single function cannot meet the requirements for electronics. Increasing attention has thus been paid to realise the functional integration among the generation, storage, and utilisation of electricity.

Integration of Generation, Storage, and Utilisation electricity

- Generation and storage of electricity

- Electric storage and utilization Integration with Sensing Functionality

- Strain and pressure sensors

- Resistive sensors

- Capacitive sensors

- Temperature sensors

- Chemical sensors

- Humidity sensors

- Self-powering sensors

Challenges

From a viewpoint of practical application, some critical challenges remain that need to be addressed. Firstly, it is difficult to fabricate highly efficient fibre and textile-shaped electronic devices on a large scale, as their performances greatly decrease, as their lengths are increased from centimeters to meters or even longer. Secondly, it is challenging to connect a bunch of fibre electrodes after the fibre-shaped electronic devices are woven into textiles. Thirdly, is the question of whether to seal the electronic textiles. They become less stable and even soon fail without sealing, but they cannot effectively display the advantages of the textile structure after sealing.

“Firstly, it is difficult to fabricate highly efficient fibre- and textile-shaped electronic devices on a large scale, as their performances greatly decrease, as their lengths are increased from centimeters to meters or even longer. Secondly, it is challenging to connect a bunch of fibre electrodes after the fibre-shaped electronic devices are woven into textiles. Thirdly, is the question of whether to seal the electronic textiles.”

Fourthly, washing the electronic textiles is problematic as they may stop working after contact with water. In summary, although a lot of studies are required to optimise the structures and enhance the properties of these smart electronic textiles, they have been demonstrated to be promising for a variety of applications. It is proposed that they may bring a technical revolution to our life soon.

Conclusion

Electronic textiles are the most exciting innovation in the field of textile engineering. The development of smart textiles reaches far beyond imagination; some stories may seem science fiction. The economic value and impact of smart textiles is gigantic. The advent of smart textiles makes it possible to being the traditional textile sector to a level of high-technological industry. Moreover, it appears that this is only possible by intense co-operation between people from various backgrounds and disciplines such as microelectronics, computer science, material science, polymer science, biotechnology, etc. Also, more research is needed to make it more convenient in our practical life.

References:

- Review on smart textiles, Wei Weng, Peining Chen, Sisi He, Xuemei Sun, Huisheng Peng Angewandte Chemie International Edition 55(2016)

- Review on wearable textiles by Joanna Berzowska Textile 3 (1), 58-75, 2005

- Electronic textiles charge ahead by Robert F Ser- vice Science 301 (5635), 909-911, 2003

- Historical review of smart e textiles, Theodore Hughes-Riley, Tilak Dias, Colin Cork Fibers 6 (2), 34, 2018

- Electronic textiles as disruptive, Kristin Searle Har- vard Educational Review 84 (4), 532-556, 2014

- Sungmee Park, Sundaresan Jayaraman MRS bulle- tin 28 (8), 585-591, 2003

- Wearble electronics and smart textiles, Matteo Stoppa, Alessandro Chiolerio sensors 14 (7), 11957- 11992, 2014

- Review on Wearable electronics, Mozhdeh Ghahre- mani Honarvar, Masoud Latifi The Journal of The Textile Institute 108 (4), 631-652, 2017

- Flexible interconnects for electronic textiles, Tal- ha Agcayazi, Kony Chatterjee, Alper Bozkurt, and Tushar Ghosh*,2017