Creation in turning factories in this pinnacle season has remained ended throughout recent days due to a serious emergency of gas for upgrading at the Bibiyana gas field. Following the suspension underway, the mill operators are expecting that the product of article of clothing things will be impacted in light of postponed supply of yarn to the commodity situated article of clothing plants. For all most recent news, follow The Daily Stars Google News channel. Normally, material and turning factories require supplies of a significant measure of gas.

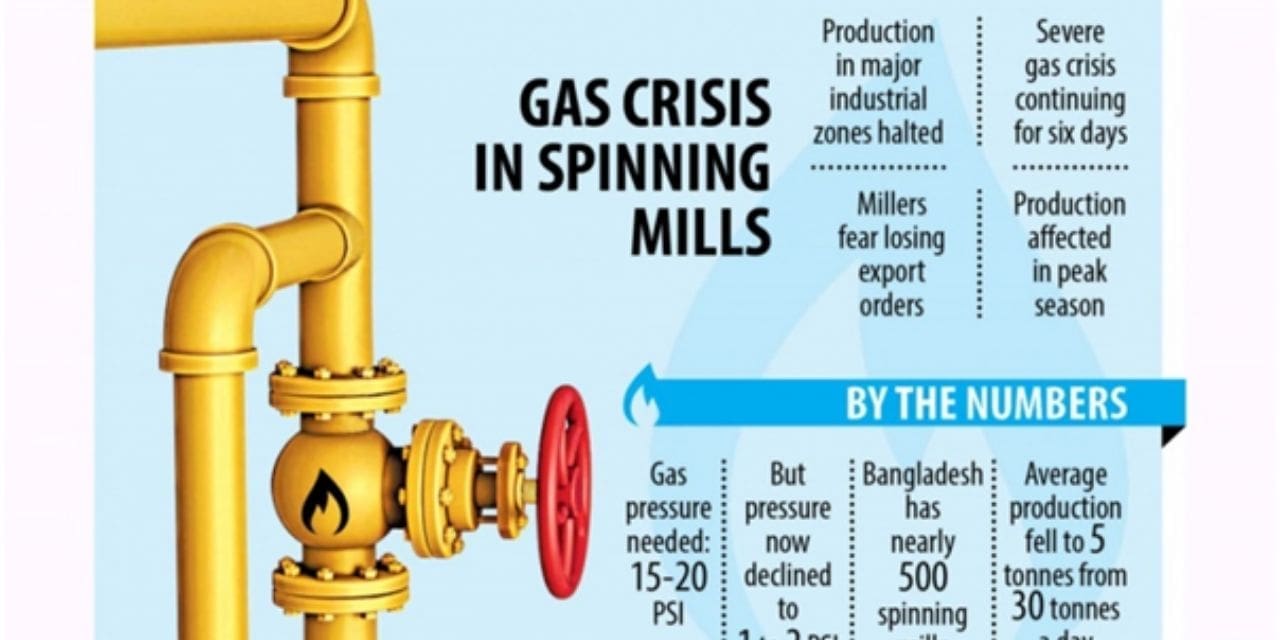

The enduring turning and material factories are in the major modern zones like Gazipur, Savar, Ashulia, Shreepur, Dhaka, Narayanganj, Narsingdi and Bhaluka. The gas pressure boiled down to 1 pound for each square inch (PSI) to 2 PSI though the necessity was 15 PSI to 20 PSI, for which the creation in the plants had remained practically suspended. On a normal day, Md Khorshed Alam, director of Ashulia-based Little Star Spinning Mills, can deliver 12 tons of yarn. Be that as it may, in the course of the most recent five days he is delivering 2.50 huge loads of yarn each day to serve weavers for the creation of article of clothing for the homegrown business sectors.

Principally, he has been causing Tk 40.50 lakh underway misfortunes consistently, Alam told The Daily Star, adding that the gas emergency had been winning for a long while yet deteriorated in the course of the most recent five days. Additionally, Estahak Ahmed, overseeing head of Bhaluka-based Nortex Textile Mills and Basher Spinning Mills, said his creation limit declined to 8 tons to 9 tons rather from 50 tons each day in view of the gas emergency. He supplies yarn to trade arranged piece of clothing processing plants. "On the off chance that we can’t supply unrefined components convenient to the article of clothing industrial facility proprietors, the processing plants will lose the purchasers and work orders in the pinnacle season," Ahmed called attention to. Fazlul Haque, overseeing overseer of Shreepur-based Israq Spinning Mills, said his creation declined to 25 tons in the course of the most recent five days while on a normal day he can deliver 125 tons.

He likewise captures that his purchasers probably won't acknowledge merchandise assuming there is a postponement as the work orders were set for a season. Assuming the season passes, the purchasers won’t have any desire to take the products, he said. Monsoor Ahmed, CEO of Bangladesh Textile Mills Association (BTMA), said consistently individuals were grumbling of misfortunes and stops underway in the factories for the intense deficiency of gas in the plants."We are preparing to evaluate the misfortunes in the plants in the course of the most recent couple of days; he said.