‘Customisation’ and ‘quick delivery’ are the current imperatives across all business sectors, and more so for apparel, home, and technical textile products. To meet these requirements, textile mills require machines featuring greater flexibility for customization and rapid production of small and irregular lots.

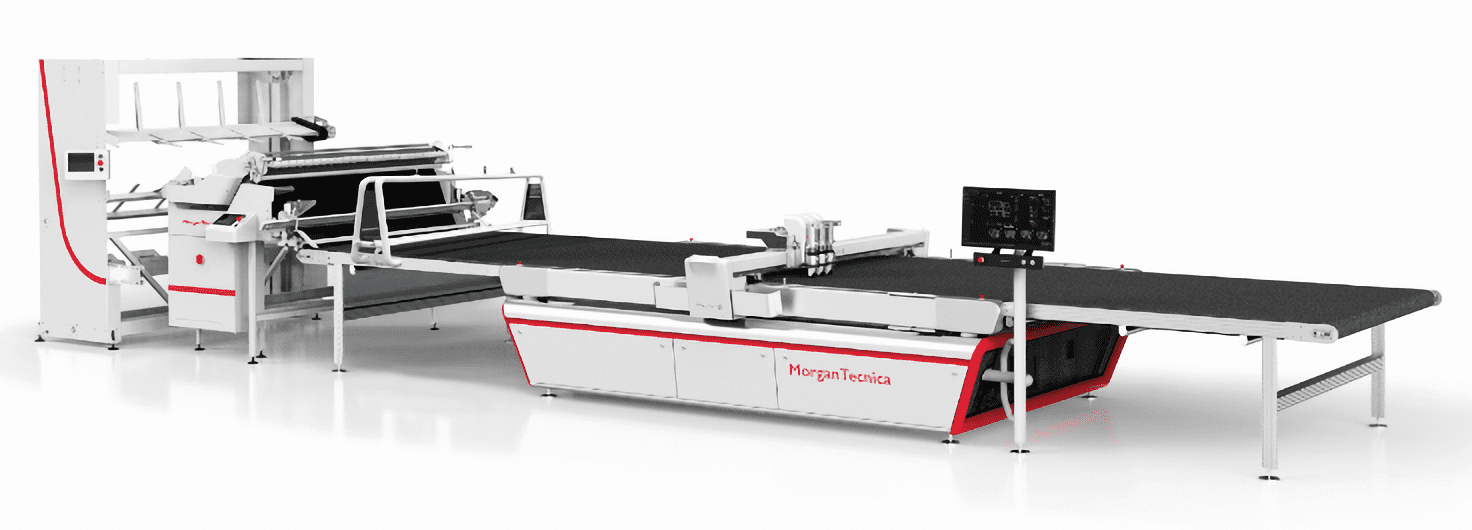

PLY1, the single-ply cutting system from Morgan Tecnica, Italy, is designed to meet the demands of the industry. This breakthrough technology, a high-performance single-ply cutting system is equipped with linear motors that offer high accuracy coupled with low running costs. The PLY1 features multiple cutting heads that can cut both soft as well as hard textile materials, PLY1 can handle all types of textiles including carpet fabric, and even special materials of different compositions and dimensions including thicknesses up to 60 mm – with great precision and high speed.

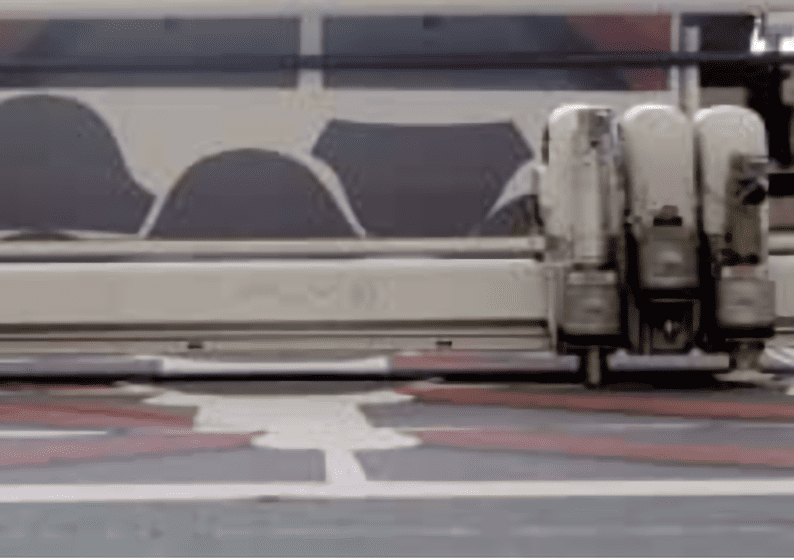

PLY1 works with different cutting windows and conveyor extensions to manage any type of material and meet every production requirement. It can be equipped with Morgan Tecnica’s VisionScan system, a fully automatic solution to monitor, scan and manage the detection and proper matching of stripes, plaids, and repeated prints. With the VisionScan system the material is preliminarily scanned before cutting, and the information is then processed by different software applications. The system then automatically shifts, rotates or even distorts (if needed) the pieces in the marker, in order to obtain proper matching, optimize the cutting time, and reduce waste.

PLY1 lines are fully customizable through different optional modules, such as the automatic fabric roll feeding, loading, unrolling cradles for fabric feeding, labelling, and collection systems for cut piece picking and sorting. This helps to meet the specific needs of each customer and industry application optimally.

PLY1 line customizable according to the customers’ needs

Printed marks matching

Cutting systems suitable for the needs of different industries.