Company’s Vision is to achieve customer satisfaction through innovation and superior quality of our products and services. The Jakob Müller Group is the no. 1 supplier of systems and solutions for the ribbon and narrow fabrics industry, providing everything from warp preparation to the final product on a one-stop-shop basis.

Expansion plan

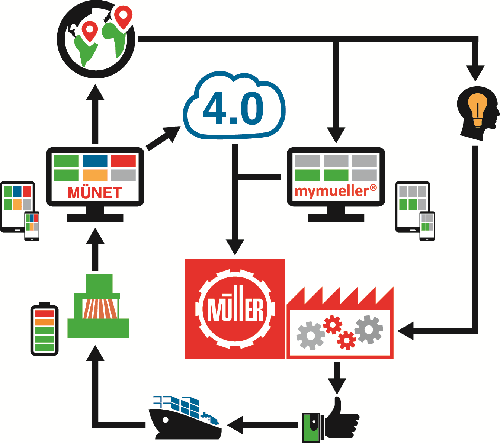

Our development plan, however does not refer to the production process only. At the same time we are working on the digitization of our services. We have recently released our service portal “mymueller®”. Besides ordering spare parts with a real time information about the delivery status, this browser based system enables our customers to download manuals and to scroll the spare parts catalogue. – via desktop, tablet or smartphone.

Our new service portal can be the access point to our production data acquisition MÜNET, a modular software, which includes a lot of tools and functions to monitor and to control the production. Further development steps towards preventive maintenance and production planning have already been launched.

Our portfolio, which we will present at ITMA 2019, will surely underpin our reputation as a world market leader in the narrow fabric industry.

Growth

In general, today’s markets are moving fast. Our customers are confronted with short lead times connected with high requirements in terms of quality and design. Therefore digitization with regard to the production process including our services is one of the main topics, we are working on.

We are strengthening our competitiveness through innovation, which clearly sets us apart from our competition and underpins our position as a market leader in our industry.

We are constantly working on innovative products and technologies. Besides our own development efforts, we are cooperating with universities and institutes. This strategy incorporates a broad and profound expertise to always ensure a state of the art solution.

Future technology

One of the main future topics in our industry will be the digitization of the production process in the context of the Internet of Things (Industry 4.0). We are therefore working in a very close partnership with the Digital Capability Center (DCC) at the University of Aachen in Germany. Together we have built up a model factory “Industry 4.0” mainly based on our machines, where we produce a woven bracelet with an integrated RFID-chip. The process is fully digitized. The finished bracelet enables an individual login at each machine. We are not only gaining a lot of experience out of this project but also offer application-oriented workshop, trainings and events, which can be booked by interested customers for their specialists and management.

Branding Strategies in India and International Market

As a company with worldwide set ups on one side and with globally acting customers on the other side, our branding strategy does not differ from market to market. Our main target is to ensure, that the worldwide perception of the “Müller”-brand is characterized by customer benefits in terms of innovation, quality and service.

We are working on the digitization of our internal processes as much as we do on our products and services and digital marketing is only one part of it. This is an ongoing, challenging process for all people involved, which however offers a lot of opportunities.

ITMA 2019 update

INNOVATING THE WORLD OF NARROW FABRICS – JAKOB MÜLLER GROUP AT ITMA 2019

The Jakob Müller Group presents only new developments, which will be released and exhibited for the first time at ITMA 2019.

A lot of innovative solutions and applications are being shown – among others the MDW technology (Multi Directional Weaving) – a technology, which constitutes a global first!

Based on this technology, Jakob Müller has developed a unique product:

VELVEDGE® – REINVENTING THE LABEL

The new VELVEDGE® selvedges replace hot wire, ultrasonic and laser label slitting systems. Consequently, they are ideally suited to top quality clothing that is worn directly on the skin. VELVEDGE®is therefore particularly attractive to brand manufacturers of articles such as sportswear, as the label remains attached to the clothing in the long-term.

The very same technology can be applied on a narrow fabric needle loom and is shown based on a

NFM® 53 2/84 MDW® NARROW FABRIC NEEDLE LOOM WITH SPECIAL LAYERING DEVICE

On this machine, Jakob Müller is showing a special tape with a conductive thread, which finally goes into aMammut® outdoor hiking boot with a heated insole fitted with a temperature sensor, electronic control and temperature regulation, as well as a switch for Bluetooth linkage with a smart phone. The related app not only allows the heating to be switched on and off, and the pre-selection of four warmth levels, but also shows the battery charging status. Nonetheless, what does the walker do when the battery is flat? Luckily, the boot contains components for inductive charging and a USB plug via which the battery can be provided with the required energy via a cable

A lot of innovation has been done in the field of needle weaving. Jakob Müller is showing the latest developments on the booth at ITMA 2019

NFM® 53 4/66 HIGH-PERFORMANCE NARROW FABRIC NEEDLE LOOM

The high-performance NFM® 53 4/66 narrow fabric needle loom is the latest product from the Jakob Müller company and has been designed for the production of light to medium-weight elastic and non-elastic tapes. The “M” in the machine designation stands for the word “modular” and for customers, means simplified modification and enlargement possibilities, increased efficiency and higher productivity.

NFMJ 80 6/66 HIGH-PERFORMANCE NARROW FABRIC NEEDLE LOOM WITH JACQUARD DEVICE

The high-performance NFMJ 80 6/66 narrow fabric needle loom is the world’s largest machine of its type and is naturally designed and built by the Jakob Müller company. The SPE3 jacquard unit has 1,536 functions and thus enables the weaving of elastic and non-elastic tapes with very fine threads. The jacquard narrow fabric needle loom on display at the fair operates using the high-middle-low principle and 768 functions are available for actual patterning.

MD 4/85 NARROW FABRIC NEEDLE LOOM FOR MEDIUM-WEIGHT TAPES AND BELTS

The MD 4/85 narrow fabric loom is a new product from the Jakob Müller Group and is designed for the production of medium-weight tapes and belts. The demand for this type of lifting and load securing product has steadily increased during recent years and in general the machines available on the market for the manufacture of such items have two weaving heads only. However, in order to create a more favourable ratio between the machine footprint and production output, Jakob Müller decided to equip a machine with four weaving heads. As a result, at a speed of 800 rpm and (theoretical) efficiency of 100%, production amounts to roughly 480 meter of tape per hour!

Another milestone has been reached with the development of the new rapier machine for the production of labels:

MÜGRIP® MBJ8 – THE NEW RAPIER MACHINE FOR LABEL PRODUCTION

Jakob Müller AG will unveil its new MÜGRIP® MBJ8 rapier loom for the manufacture of labels. With a production speed of 680 rpm and a maximum reed width of 1,380 mm, the machine offers the efficient output of labels, images and technical narrow fabrics with slit selvedges. The machine will be shown with a lot of new and innovative features making it the most efficient one in the market.

The group’s brand COMEZ will show their latest innovations in crochet and warp knitting:

DNB/EL-32-12B ELECTRONICALLY CONTROLLED WARP KNITTING MACHINE WITH DOUBLE NEEDLE BED

Electronically controlled warp knitting machine with double needle bed for the production of articles for technical and medical uses as well as garment textiles.

The machine is available now with 12 electronically controlled guide bars for development and production of advanced technical fabrics.

800 ACO/EL CROCHET KNITTING MACHINE

Crochet knitting machine with compound needles,electronically controlled yarn tension device and stitch density regulation, for the production of a wide range of technical textiles, with lock-stitch structure, both elastic and rigid.

The compound needle machine is available now with 800 mm working width. It is equipped with 8 weft bars controlled by chain links with involute profile.

A lot of innovation has also been done in the field of dyeing and finishing. Jakob Müller shows a development, that meets the increasing requirements in terms of ecology:

NEW ECO WASH TANK

Jakob Müller launches a new type of wash tank for the continuous dyeing of narrow fabrics.

This wash tank module is part of the MFR dye lines.It combines highest efficiency in washing process for best colour fastness with significant lower demand on water, chemicals and energy to save resources and costs.