Clothing has become a fashion statement reflecting the wearer’s personality and the image a person wants to convey. However, as the fashion industry has expanded, so have concerns about the impact that clothing has on the environment, from how the fibres – the basic raw material for textiles and clothing – are sourced to what happens to the clothing when the useful life of a clothing item is over.

All the stakeholders are now more concerned and are expecting the industry to take responsibility for better management of the complete value chain. Since the value chain starts with fibre suppliers, a lot of the onus falls on them to supply sustainable raw materials. This is where eco-friendly fibres have gained attention from the value chain and now also an increased share of the market.

Man-made Cellulosic Fibres (MMCF) such as viscose, modal, and lyocell fill that gap and have been increasingly seen as one of the best sustainable raw materials for the fashion industry. MMCF can be responsibly produced by using a closed-loop manufacturing process, which reduces the impact on natural resources. At the end of its life cycle, MMCF is biodegradable and compostable.

Birla Cellulose

India-based Birla Cellulose is one of the leading producers of MMCF globally. Birla Cellulose has strong backward integration and operates 11 pulp & fibre manufacturing sites across 6 countries and 5 R&D centres. As a global leader in the MMCF industry, Birla Cellulose takes pride in playing a major role in the transformational journey of the global fashion industry in taking a sustainable growth path.

The wood-based fibres are fully renewable and come from sustainably managed forests. Birla Cellulose is a market leader in the use of sustainable forestry practises and closed-loop environmentally efficient technologies that recycle raw materials and conserve natural resources.The responsibly produced fibres provide extensive and unmatched sustainability benefits that fulfil the growing demand for sustainably designed fashion products.

Responsible Sourcing

Birla Cellulose is a leader in sustainable sourcing – # 1 in the Hot Button Report 2020 – and has achieved a “dark green shirt” ranking, confirming that there is a low risk of sourcing wood from ancient and endangered forests when consumers are using Birla Cellulose fibres.

Responsible Manufacturing

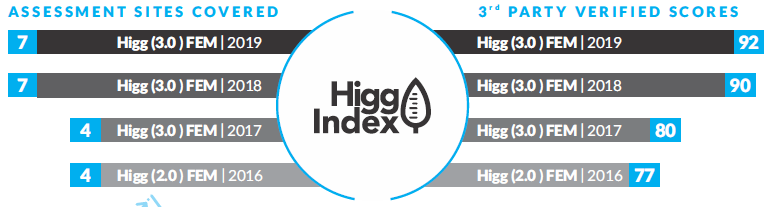

Globally benchmarked Higg FEM Scores –The Higg Facility Environmental Module (Higg FEM) is a sustainability assessment tool that standardizes how facilities measure and evaluate their environmental performance, year over year.

Birla Cellulose has implemented ZDHC wastewater guidelines at all the fibre manufacturing sites. With concentrated efforts, all sites exceeded the Suppliers to Zero Progressive and Aspirational Level for more than 90% of the parameters. The data from all the sites is available on the ZDHC Gateway. While all sites already meet the ZDHC MMCF wastewater standard and all the parameters specified on consumption norms in the ZDHC Responsible MMCF standards, many of the sites are already meeting the ZDHC MMCF air emission standard, while other sites continue to work towards it.

Sustainable Fibres

With a strong focus on innovation, Birla Cellulose has come up with eco-enhanced products along with other MMCF offerings. Livaeco by Birla Cellulose™& Liva Reviva are the latest innovative products with a host of benefits for the value chain and the overall fashion industry.

Livaeco by Birla Cellulose™ is the latest fibre from Birla Cellulose with a host of sustainability features while retaining the fashion quotient of the brand. Key features of Livaeco are:

- Sourced from 100% sustainable forestry – Birla Cellulose sources wood from certified forests with complete ‘chain-of-custody’

- Responsible Manufacturing – manufactured in best environmentally sensitive facilities with EU BAT certification and lower non-renewable energy use

- Transparency & traceability – Sustainability conscious consumers through scan of QR code can verify source through in-house developed blockchain based platform GreenTrack™

- Lower emissions – Livaeco has 75% lower water consumption and 65% lower GHG emissions as compared to generic viscose based on Higg MSI provided by SAC.

Value Chain Transparency

GreenTrack™ Platform – Through its pioneering platform GreenTrack™ based on blockchain technology, Birla Cellulose, along with its value chain partners, provides complete transparency for the entire journey of eco-enhanced fibres like Livaeco, Liva Reviva and other eco-enhanced fibres from a certified forest up to the consumer’s hands on a ‘live’ basis. Consumers, through a simple scan of a QR code, are able to see the entire journey of the garment.

For more details, please visithttps://www.birlacellulose.com/