One of the fastest growing sectors in textile industry is technical textile Considerable attention is taken away, using of fibres, yarns isn’t a new phenomenon now. Nor is it exclusively linked to the emergence of recent artificial fibres and textiles. What is relatively new may be a growing recognition of the economic and strategic potential of such textiles to the fibre and fabric manufacturing and processing industries of commercial and industrialising countries alike In a number of the foremost developed markets, technical products (broadly defined) already account for the maximum amount as 50% of all textile manufacturing activity and output.

The technical textiles supply chain may be a long and sophisticated one, stretching from the manufacturers of polymers for technical fibres, coating and speciality membranes through to the converters and fabricators who incorporate technical textiles into finished products or use them as a crucial a neighbourhood of their industrial operations. The scope of technical textile exceeds far beyond textile

industry and has an impact on social and individual human aspects too.

The current technical textile provides range of niche solutions to markets with use of IT, science and some unique materials. Adaption of new plans and ideas is now a new strategy for current textile industries. At a competitive cost there is use of new innovative advanced textiles with structure, appearance, aesthetics, functions etc.

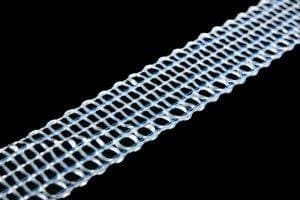

E-WEBBINGS

This are woven narrow fabrics, thin which acts as a conductor for transmission of electric signals and data that can be light, heat, vibrations and energy which may be stored. These special conductive fibres may be in conjunction, woven with other fibres, there uses embedded sensors in integral technology and wearables, with internet.

Advanced conducting and sensing technology is currently in development. Which composes of sophisticated processes for weaving and with high performance the combination of fibre optic filaments and structural materials. Structured outputs are the optical carriers in weaving here. In assemblies of eventual construction, it is serving as a component part. This part transmits and capture the information to downstream the computing technology.

Corrective majors and actions are being taken by the optical tech. The monitoring capacity is improved acts as assistant assisting the optimization and manufacturing processes and integration of non-destructive inspection tools.

These advanced textiles developed by BRM, can be used in safety harnesses, chemically resistant webbing parachutes and personal protective equipment (PPE). These are developed by multiple style class 8 looms, that is shuttle, needle, jacquard, rapier. From prototype to full scale production can be scaled by BRM.

References:

- https://advancedtextilessource.com

- textileworld.com

- https://www.solarfabric.com/category/advanced-textiles/page/3/

- Featured image source: textileworld.com

Author:

NIDHI THAKRE

Intern, Textile Value Chain