Abstract:

We have all heard about silk obtained from the silkworm, but do you know silk produced from a spider? Yes, you heard right. Mother nature provides us with many biocompatible and biodegradable materials which are yet to be discovered, and spider silk is one of the newest discoveries. Spider silk is as tough as steel and flexible as a string of the guitar. Though spider silk is useful for various applications, it is difficult to produce it on a large scale. We can get spider silk from nature or milking silk from a farm of spiders, but it is not sufficient as each spider can make only a small amount of silk which is not enough even for one dress. Thus, to overcome this problem, researchers and scientists have been recently exploring the new idea of using a marine photosynthetic bacterium as a bio factory. This study will be opening the door to produce materials that are environmentally friendly and sustainable.

What is spider silk?

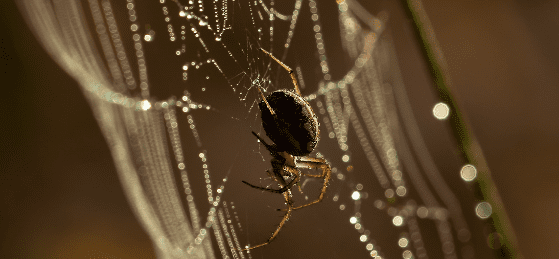

Spider silks are composed of protein fibres that are secreted by glands that are present in the abdominal or rear part of the spiders. The raw material present in the silk is the liquid protein that passes through the silk-spinning organs called spinnerets. This liquid protein becomes dry as it comes out from the spider body and forms a thread.

Female spiders can produce seven types of silk for different functions like major ampullate that is called the dragline silk for escaping from a predator. Minor ampullate for stabling the platform during web construction. Flagelliform silk is the one to capture the spiral of an orb web. Pyriform silk is for attaching all other types of silk. Aggregate silk is produced for preventing the prey from escaping. Cylindriform or tuniliform silk is produced for covering and protecting the eggs. Aciniform silk is produced for the lining of the inside of egg cases, wrapping the prey, and for attaching the pyriform silk.

Spider silk has interesting combination property of high strength and extensibility; thus, this results in its great toughness and flexibility. Also, it can focus light and can shrink as a response to humidity. Spider silk is made of multiple threads and each thread consists of spidroins which is a specific silk protein.

What are spidroins?

Spidroins are simply the proteins that are majorly used to form spider silk fibres. These spidroins are large proteins that have repetitive sequences. This repetitive sequence is the reason for the toughness of the fibres. But different types of silk have different repetitive sequences thus the toughness in them will also vary depending on the sequence type.

How is Spider Silk Produced?

To develop an environmentally friendly factory for spider silk production, researchers took a look closer at a purple-colored marine bacterium. The reason to select this micro-organism as a bio factory is that it requires only seawater, source of sunlight, carbon dioxide, and nitrogen to survive. To research more about the production through marine microorganism, the researchers did a study to synthesize MaSp1 that is one of the main dragline silk spidroins. They introduced the plasmid that was carrying the MaSP1 gene into the purple mom sulphur bacterium and then confirmed the MaSp1 protein. For making this on large scale they selected the largest repeat of MaSp1 and harvested a good quantity of intact silk. This study showed a promising result that by using a microbial cell factory it is possible to produce a biomaterial like a spider silk.

Where is spider silk used?

For many thousand years, native people have been collecting spider silk for making fishing lines, fishnets, headgear, and bags. Though, the potential of spider silk is more than this and yet it has to explore worldwide.

In the textile industry, we have been using mulberry silk, but it has some disadvantages like wrinkling, degradation low wet resiliency, and UV- induced yellowing. In the year 2009, The American Museum of National History revealed a tapestry that is 11 by 4 feet which is entirely made from spider silk. More than one million spiders were used in making this tapestry. It was time-consuming and laborious work as it took 70 people to collect the spiders and 4 years to finish the making of the tapestry.

As spider silk has superior strength, it can overcome some disadvantages of silkworm silk. Though, the textile industry needs more research and innovation to make spider silk production on a large scale.

Silk proteins are also consisting of crystalline and non-crystalline regions. Spider silk is used in super lenses due to its transparency and ability to focus light. One can observe minuscule structures like viruses, germs, or inside cell structures, using super lenses made from spider silk.

Conclusion:

Spider silk is the newest discovery in the textile industry, thus there are many areas yet to be explored. Spider silk has a promising future in the industry therefore, we can expect a new era in the silk sector in the future.

References:

Decoding the secrets of spider silk – by Lucas Eisoldt, Andrew Smith and Thomas Scheibel

Spider Silk – From: Silk (Second Edition), 2019

https://www.sciencedirect.com/topics/engineering/spider-silk

Synthetic spider silk production: Finding the eco-friendly bio factory – by Tyasning Kroemer, Ph. D

Unraveling the mysteries of spider silk – by Katherine Martin