Abstract:

A good number of Technical Textile Industries are located in Daman, Valsad & Dadra Nagar Haveli (DVD) Area in Gujarat both in Organized as well as Small & Medium Sectors. Technical Textile is a growing area both in Indian and Global Scenarios. Technical Textile is a value added textile with performance and functional properties rather than their aesthetic or decorative characteristics.

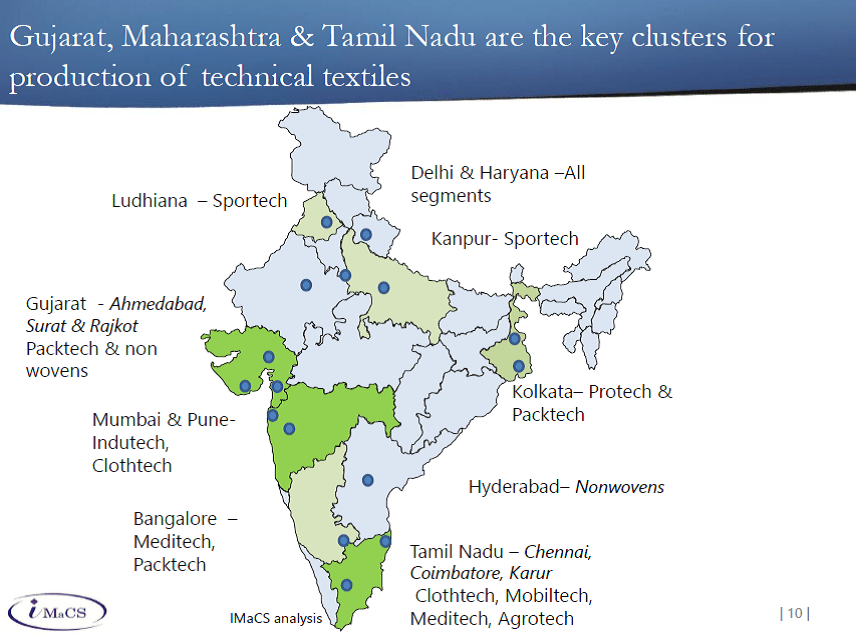

Gujarat, Maharashtra and Tamilnadu have the key clusters for production of Technical Textiles in India. Centres of Excellence (COEs) for Technical Textiles have been established to support the industries and customers.

Due to a variety of end users, the Technical textile manufacturing offers wide scope for development and innovation.

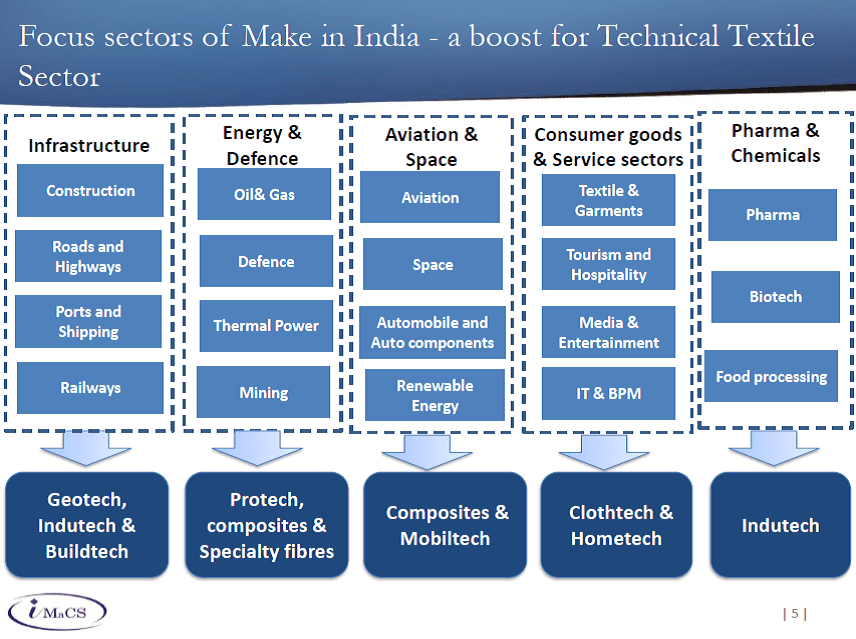

Focus sectors of Make in India Programme gives a boost to Technical Textile Sector which consists of different segments, classified based on end users. Packtech is the leading sector in terms of volume and value .Both Natural and Manmade fibers are used as raw materials for the manufacture of Technical Textiles.

Introduction

DVD represents Daman, Valsad and Dadra Nagar Haveli (DVD). It is welcome & heartening news to note that DVD area has all the Textile industries representing the Textile Value Chain.

It has been corroborated by the fact that

Umergoam has Weaving and Garmenting Industries,

Silvassa has Polyester Drawing Industries,

Daman has Polyester Manufacturing and Garment Industries,

Vapi has Textile Processing Industries as well as

Organized Sector Textile Industries – Welspun, Raymond, Alok, GHCL, Sarla, Sutlez, Walson and Others.

In Technical Textiles area, they are represented by , Alok, Faze Three Limited, Khator Technical Textiles, Kusumgar, Madura Industrial Textile, Sarla Performance Fibers, Savla Laminates, Sheela Foam, Supreme Nonwovens, Yamuna Machineries (Technical Textile Machinery Manufacturers), Welspun and a group of small and medium size Technical Textile Industries.

Key factors for the concentration of Textile Industry including Technical Textiles in DVD Area

- Availability of Skilled manpower from ICT, Mumbai, DKTE, Ichalkaranji, MS University, Vadodara, Surat, Ahmedabad.

- Nearer to Technical Textiles COEs (Central of Excellences) –BTRA, Mumbai, SASMIRA Mumbai, WRA, Mumbai, MANTRA, Surat, ATIRA, Ahmedabad.

- Very good rainfall, Nearer to Mumbai, Surat & Ahmedabad – port & transportation and other infrastructures, Availability of Entrepreneurship, Market, Innovation & Development.

- Assistance both from Central & State Governments. Backing of Active Industrial Associations and their Management Teams.

Technical Textiles

Technical Textiles have a significant part of growth in world textiles .It represents about 31% of the total Textile Production.

Technical textiles are defined as textile materials and products used primarily for their technical performance and functional properties rather than their aesthetic or decorative characteristics.

Other terms used for defining technical textiles include industrial textiles, functional textiles, performance textiles, engineering textiles, invisible textiles and hi-tech textiles.

Technical textiles are used individually or as a component/part of another product. Technical textiles are used individually to satisfy specific functions such as fire retardant fabric for uniforms of firemen and coated fabric to be used as awnings.

As a component or part of another product, they are used to enhance the strength, performance or other functional properties of that product as done by the tyre cord fabrics in tyres and interlining in shirt collars.

They are also used as accessories in processes to manufacture other products like filter fabric in food industry or paper maker felt in paper mills

Growth Drivers – Key factors defining potential opportunités forTechnical Textiles in India

- Growing domestic consumption & Enhanced requirement from institutions

- Promising export potential

- Changing regulations & industry norms

- Re-alignments of Global Supply chain & multi country trade partnerships

- Rising incomes and an increasing standard of living along with advances in medical technology,

- Expanding construction sectors,

- An awareness of safety and environmentalism and

- Increased spending on healthcare.

Technical Textile Industry in DVD Area

- Organized Sector of Technical Textile Industry in DVD Area

1. Alok Industries Ltd, Vapi, www.alok.com

- Vertically Integrated Textile Company both in cotton and Polyester

- Modern manufacturing facilities with Integrated Management System Certification

- More than 25 years of experience and produce a wide range of textile products

Product Range – 20 million Meters per annum (within Apparel fabrics)

Product type on offer (special finishes)

- Flame retardant Treated & Inherent• High visibility •Chemical splash• Oil resistant

- Anti bacterial finish• Mosquito repellant •Teflon coated• Fabric for combat uniforms• Anti static fabric

- UV protective• Moisture management • IRR finish• Army Camouflage and other

Fibre specifications – 100% cotton, polyester/cotton, cotton/nylon, Protex, Teijin Conex, Metaramid (Kermel), Lenzing FR, steel fiber, carbon fiber, polyester/tencel & cotton/tencel

Quality Certifications • Oeko Tex Standard 100• GOTS: Global organic Textile Standards

- OE 100: Organic Exchange certification• Eco Cert• EU Flower• Swan

2. FAZE THREE LIMITED, Vapi (FTL) www.fazethree.com

Faze Three Limited is engaged in the manufacture and export of home textiles, cotton handlooms, furnishing fabrics and textile made-ups.

FTL’s revenue is mostly derived from the International Market. The key export market includes United States, United Kingdom, Canada, Germany, Australia, South Africa & Brazil. The Company has reputed clients like Wal-Mart, ASDA Stores, Marks &Spencer’s, Mother Care, William Sonoma, Dollar General etc.

The company develops products as per customers’ requirements to deliver customized products to its buyers and to meet buyer’s expectations.

Car seat covers, outdoor fabric – Dadra, DNH.

Car seat covers, outdoor fabric -New Delhi.

Showroom and factory for bathmats, hand woven accent rugs and cushions- Panipat.

Blankets shower curtains, bedspreads mattresses, duvet covers and cushions -Silvassa.

Latex bathmats, kitchen mats, area rugs –Dadra, DNH.

Dyeing and processing of products- Vapi.

3. Khator Technical Textiles Pvt. Ltd, Naroli, Silvassa, DNH (KTTL). www.khator.com

Khator is one of the latest manufacturers of specialty technical textiles with the most sophisticated equipment and processes in India, manufacturing high-quality needle-punched technical non-woven fabrics for a wide range of applications.

Highlights – Fully Automated Manufacturing Facilities, Extensive Experience, Professional management Team, Adherence to Global Quality Standards, Enhanced Cost Competitiveness and Wide Range of Custom Made Products.

Applications – ROAD CONSTRUCTION PROJECTS, WATER-RELATED PROJECTS, RAIL CONSTRUCTION PROJECTS, FLOOD MANAGEMENT PROJECTS, LAND-RELATED PROJECTS, WASTE MANAGEMENT SYSTEM.

4. Kusumgar Corporates, Vapi www.kusumgar.com

A leading ISO 9001: 2008 certified Indian icon in the Technical Textiles and Specialty Textiles.

Product Range consists of Armed Forces Fabrics, Industrial Fabrics, Geo Synthetics, Sports and Recreational Fabrics, Custom Fabrics & Technical Textile Consulting.

Excellent infrastructure for Weaving, Processing & Finishing including sophisticated R& D as well as testing facilities.

5. Madura Industrial Textiles (MITL), Sarigam & Silvassa www.maduratex.com

Established over a hundred years ago, Madura Industrial Textiles (MITL) is a trust inspiring name offering

Industrial fabrics for tires, conveyor belts and mechanical rubber goods industry. MITL was formerly a division of Madura Coats Limited which was acquired by the flourishing Kalra Group of Companies in 2003.

MITL also produces its own Nylon 6 Polymer & Nylon 6 Yarns to support its own production.

Highlights

- Sustained Expertise, Technical Upgradadtion with Consistent Support,

- State of Art Production Facilities, Diverse Customer Base Covering Multiple Industries,

- Rich History, Experienced Leadership & Culture of Excellence,

- Commitment of Mutual Growth with Business Partners.

Products Range

- Nylon 6 chips, Yarns, Nylon Tire Cord, Polyester tire cord, Dipped Nylon Polyester,

- Tire cords to Tire Fabrics, Liners & Leaders Fabrics,

- Conveyor Belting Fabric, Tire Fabrics, Tire Cords, Tire Chafers, Liners & Leaders

- Specialty Fabrics – Diaphragm Fabrics, Synthetic Tape Fabrics, Hose Fabrics, Fabrics for Defense, Filter Fabrics

6. Sarla Performance Fibers Limited, Vapi. www.sarlafibers.com

An ISO 9001:2008 Certified Company, Sarla Performance Fibers Limited (formerly known as

Sarla Polyester Limited) is a 100% EOU engaged in the manufacturing and export of polyester and nylon textured, twisted and dyed yarns, covered yarns, high tenacity yarns and sewing thread.

Nylon 6 & Nylon 66 find application in Parachutes, Shoes, Seat Belts and Car Airbags

High Tenacity Nylon & Polyester find application in Fishing Nets, Twines, Filter Fabrics & Industrial Applications

Sarla Performance Fibers Limited is the only company in India to manufacture Nylon 66. Nylon 66 is high tenacity and lower shrinkage yarn product.

Product applications: Parachutes, Shoes, Seat Belts & Car Airbags, Specialized Sewing Applications in Automotive, Shoes, Leather, Industrial Filters, Hoses.

Both High Tenacity Nylon & Polyester form raw materials for the manufacture Technical Textiles mentioned above

7. Savla Laminates Limited, Vapi www. savlalaminates.com

Savla Laminates Limited is one of the leading manufacturers of LAMINATED PVC man made fabrics and cotton coated fabrics in India.

Product Portfolio -PVC Laminated Fabrics, Luggage Material, Seat Covers Material, School Bag Material, Jeep Hood Material, Canopy Material ,Tarpoline Materials, Inflatables Material and Luggage Bag Fabrics.

Very good infrastructure for Manufacturing, R&D, Quality Assurance and committed work force.

Has the state of the art in house fabrication facility. Some of the regular types of fabrication works carried out are: Tarpaulin, Truck cover, Fumigation cover, Flexible water tank and Tensile covers

8. SHEELA FOAM LIMITED www.pufoammanufacturers.com www.sheelafoam.com

Established in the year 1972, Sheela Foam Limited an ISO 9001:2008 certified company

is the pioneer in manufacturing, exporting & wholesaling of PU foam in India.

Have developed 10 manufacturing facilities in India and 5 manufacturing facilities in Australia. These manufacturing facilities are well equipped with sophisticated machinery and latest technology to ensure optimum quality production.

Key Customers – Addidas Limited, Steel Bird, Liberty Shoes, Nike Shoes.

Major Markets – India, East Asia, Middle East, South East Asia, Indian Subcontinent.

Products comprises of:

- Hard Foam – Sole of Shoes, Foam for Automobile parts, Shoe upper foam

- UV Stable white foam – Foam for clothing, sports shoes, inner wears and ladies undergarments

- Reticulated Foam – Reticulated Foam, Foam for Air Filters and Oil Filters

- Visco foam – Mattress overlay foam, Medical Mattress foam

- High Resilience Foam – High quality bedding foam, Furniture Foam

- Acoustic Absorption Foam – Acoustic Absorption Foam, DG set canopy foam, Engine testing room foam, Sound Insulation foam

- Polyester Foam .8. Other Products – Mattresses, Pillows, bolsters & back cushions, Ready to use furniture, Cushioning for furniture, Polyether foams, Polyester foams, Special Foams

Range of products are excessively used in Acoustic insulation, Air conditioning, Apparels, Automobiles, Aviation, Bedding, Electronics, Packaging, Thermal Insulation and several other applications.

9.Supreme Nonwoven Industries www.supremegroup.co.in

The largest and most diversified Nonwovens Company in India

A team of over 2000 members based at 11 world class manufacturing facilities

Product Range

- Automotive components (Trims, NVH components etc.)

- Filtration (Industrial filtration media for Air, Water, Oil filtration etc.)

- Garment Interlining / Shoe Insole ,• Geo-Textile Applications,

- Other Industrial Application.

10. Welspun India Ltd, Vapi/Anjar www.welspunindia.com

![]()

Welspun India Ltd, a leading home textiles manufacturer, has established a new Rs 150 crore state-of-the-art needle entangled advanced textile plant in Anjar, Gujarat, to further advance its Technical Textile Business capabilities.

They are entering into an exciting phase of business through these new offerings in technical textiles.

This facility will have unique capabilities of spunlace and needle punch lines, which can manufacture multilayer composites for various applications.

This advanced and innovative technology will provide nonwoven solutions for high-end industrial applications such as filtration, acoustics, automotive, fire safety, thermal insulation, vibration control, noise control, aerospace, defence and mass transportation.

The initial capacity of the manufacturing unit will be 2,400 MT per annum. Welspun has also invested in a wide range of finishing technologies, which include coating, laminating, dyeing, and printing, to provide innovative solutions; all under one roof.

11. Yamuna Machine Works Limited www.yamunamachine.com

Yamuna is one the leading manufacturers of machinery for textile processing, finishing and associated branches of industries including for Technical Textiles.

YAMUNA started with sole aim – To design and deliver equipments for processing and finishing which will enhance the productivity of the system as a whole to produce quality textiles and reduce the energy costs.

Product Range

- Stenters, Hydraulic Jiggers, Singeing Machine (with Bejimac), Denim Finishing Plants (wet finishing, foam finishing, deszie-mercerise ranges, coating with stenter),

- Drying Ranges, Relax Dryers, Cold Pad Batch Dyeing,

- Coating and Laminating Plants for technical textiles, Dipping Line, Thermo Bonding Line Finishing Machines for Non-Wovens- Thermo Bonding Lines& Hot Calender for Non- Wovens, Drum Dyer for Non-WovensCuring Machine – Polymerizer

- Carpet Backing Lines, and Pre/Post Treatment machines for Digital printed fabric

Technical Textile Industry in DVD Area

Small and Medium Sectors of Technical Textile Industry in DVD Area

| 12.List of Companies Engaged in Manufacturing of Agrotech Products |

| Name, Location, Products |

| ARD Polymer, Silvassa ,Crop Protection Net |

| Fiberweb India Ltd, Silvassa, Woven and nonwoven crop covers |

| Globe Cast, Umbergaon, Fishing net and fishline |

| Jayshree Marine nets, Nani Daman ,Fishing net and fishline |

| Rishi Packer, Silvassa ,Crop Protection Net |

| Unimin, Silvassa, Shade Net/fabrics |

| 13.List of Companies Engaged in Manufacturing of Agrotech Products |

| Name Location Products |

| Balaji Polynets, Vapi, Gujarat, Shade nets |

| Br Agri Factors, Daman, Shade nets and monofilament nets |

| Flora Agrotech, Vapi Gujarat, Shade nets, monofilament nets |

| Fortune Agro nets Vapi, Gujarat Shade nets, poly sacks |

| Hari Om Polysacks Vapi, Gujarat Shade nets, polysacks |

| Rajvi Plastotech Pvt. Ltd. Vapi, Gujarat Shade nets |

| R. R. Polynets, Valsad, Gujarat, Shade nets, insect nets, bird protection net, pond liners |

| Venkatesh Agro shde nets, Vapi, Gujarat Shade nets |

Overall, market drivers of Global Technical Textiles include:

Global population growth, Replacement of conventional building materials, increasing complexity of industrial production, Expansion of healthcare, Growth in vehicle production, Growth in expenditure on sport and leisure products and Permanent opening up of new areas of application.

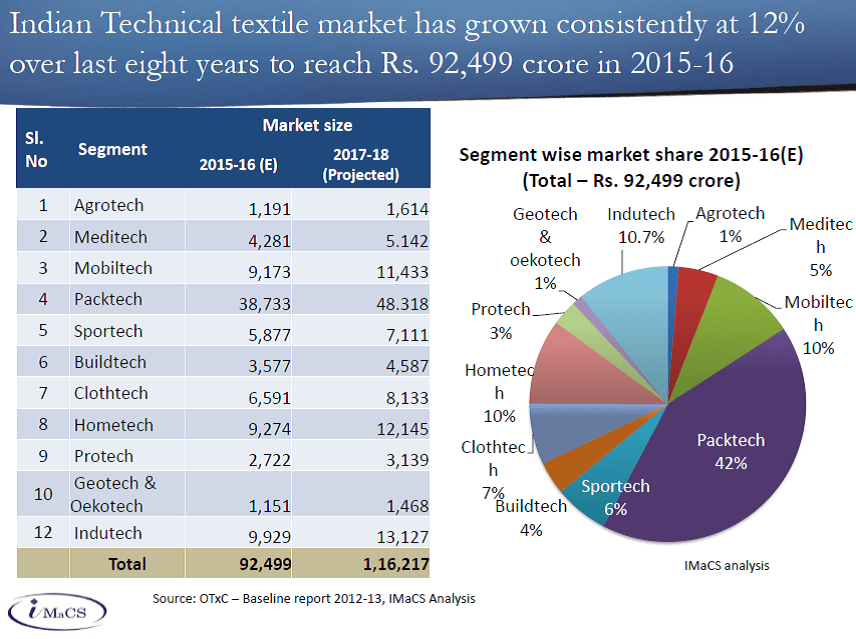

Table – 1& 2, Source: Indian Technical Textile Industry: Current Scenario & Opportunities, Techtextil, India Symposium 08, September, 2016 by ICRA Management Consulting Services Limited.

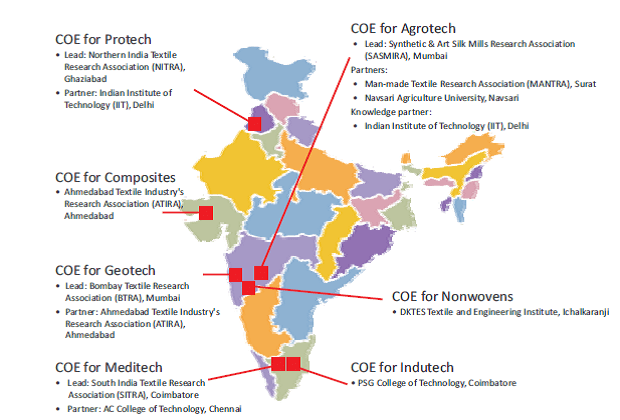

Details of Centers of Excellence

Product Focused Centers of Excellence

- The Bombay Textile Research Association (BTRA), Mumbai – Geotextiles & Oekotech

- Synthetic & Art Silk Mills Research Association (SASMIRA), Mumbai – Agrotextile & Packtech

- Northern India Textile Research Association (NITRA), Ghaziabad – Protective Textiles & Mobiltech

- South India Textile Research Association (SITRA), Coimbatore – Medical Textiles

- PSG College of Technology, Coimbatore – Industrial Textiles & Hometech

- Wool Research Association (WRA),Thane- Sports Textiles

Process Focused Centers of Excellence

- D K T E’s Textile & Engineering Institute, Ichalkaranji, Kolhapur – Non-Wovens & Clothtech

- Ahmedabad Textile Industry’s Research Association (ATIRA), Ahmedabad-Composites & Buildtech

Centre of Excellence in Technical Textiles in India

Table -3

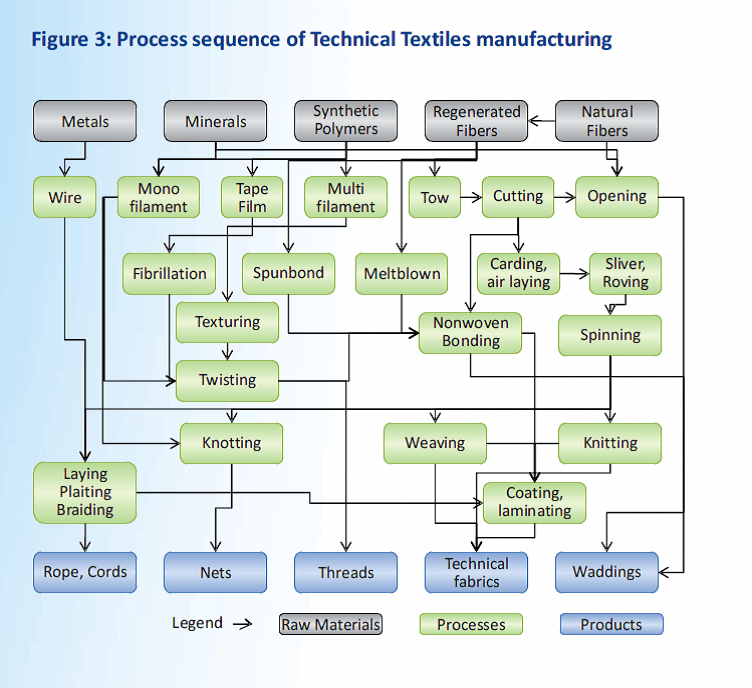

Details of raw-materials for technical textiles

Technical Textiles are manufactured from a variety of fibres/filaments based on the desired properties of the end product. The fibres/filaments used can be broadly classified as Natural and Man Made.

Natural Fibers – Cotton, Jute, Silk, Coir

Man – made Fibers- Polyester, Nylon, Acrylic, Modacrylic, Polypropylene, HDPE, LDPE, LLDPE

Table-4

Table – 4, Source: OTxC – Baseline report 2012-13, IMaCS Analysis, Indian Technical Textile Industry: Current Scenario & Opportunities, Techtextil, India Symposium 08, September, 2016 by ICRA Management Consulting Services Limited

Technical Textiles –Market

| India: Technical Textile Scenario 2007-2017 Table – 5 | |||

| Year | 2007-08 | 2012-13 | 2016-17 |

| Value in US $ Bn | 7 | 15.2 | 26.33 |

| 2007-08 to 2012-13, annual growth rate of 11%registered. 2012-13 to 2016-17, annual growth rate of 20% expected. |

|||

Table – 5 Sources: Seshadri Ramkumar, TexSnips, July 3, 2013, Technical Textiles Creating Value for Spunbond Nonwovens, Presented at: THE SOUHTERN GUJARAT CHAMBER OF COMMERCE & INDUSTRY, SURAT, INDIA MARCH 24, 2014

| Worldwide: Demand for Technical Textiles Table- 6 | ||||

| Year | 2010 | 2011 | 2012 | 2018 |

| Value in US $ Bn | 122 | 126 | 133.93 | 160.38 |

| Asia Pacific Region – Real Power Engine for Global Technical Textiles Market. | ||||

Asia’s Influence on the Global Technical Textiles Market

Asian Technical Textiles Market Share in Global Technical Textiles Market In 2011, 45% in 2018, 61% (expected).

Key markets – China, India, South Korea, and Taiwan. Key Sectors – Automotive, Infrastructure Agriculture, Protective Textiles, Health & Medicare.

Table -6 Sources: IFAI Specialty Fabrics Review, February 2012 and Transparency Market Research, USA, July 5, 2013, Technical Textiles Creating Value for Spunbond Nonwovens, Presented at: THE SOUHTERN GUJARAT CHAMBER OF COMMERCE & INDUSTRY, SURAT, INDIA MARCH 24, 2014

A large part of future growth in world textiles is going to come from Technical

Textiles. World Textile Production in 2014 – 89 Million Tons, Conventional Textile -69% and Technical Textiles – 31%.

Technical Textile Production – 28.1 Million Tons which consists of the followings

- Knitted, Woven, Braided and Yarn Type – 15.65 Million Tons

- Non Wovens – 8.55 Million Tons

- Composites (Textile share without matrix) – 3.9 Million Tons

Source: Technical Textiles & Nonwovens a global market – a global market overview by Messe Frankfurt Exhibition GmbH, www.techtextil.com

India’s positioning in global industry

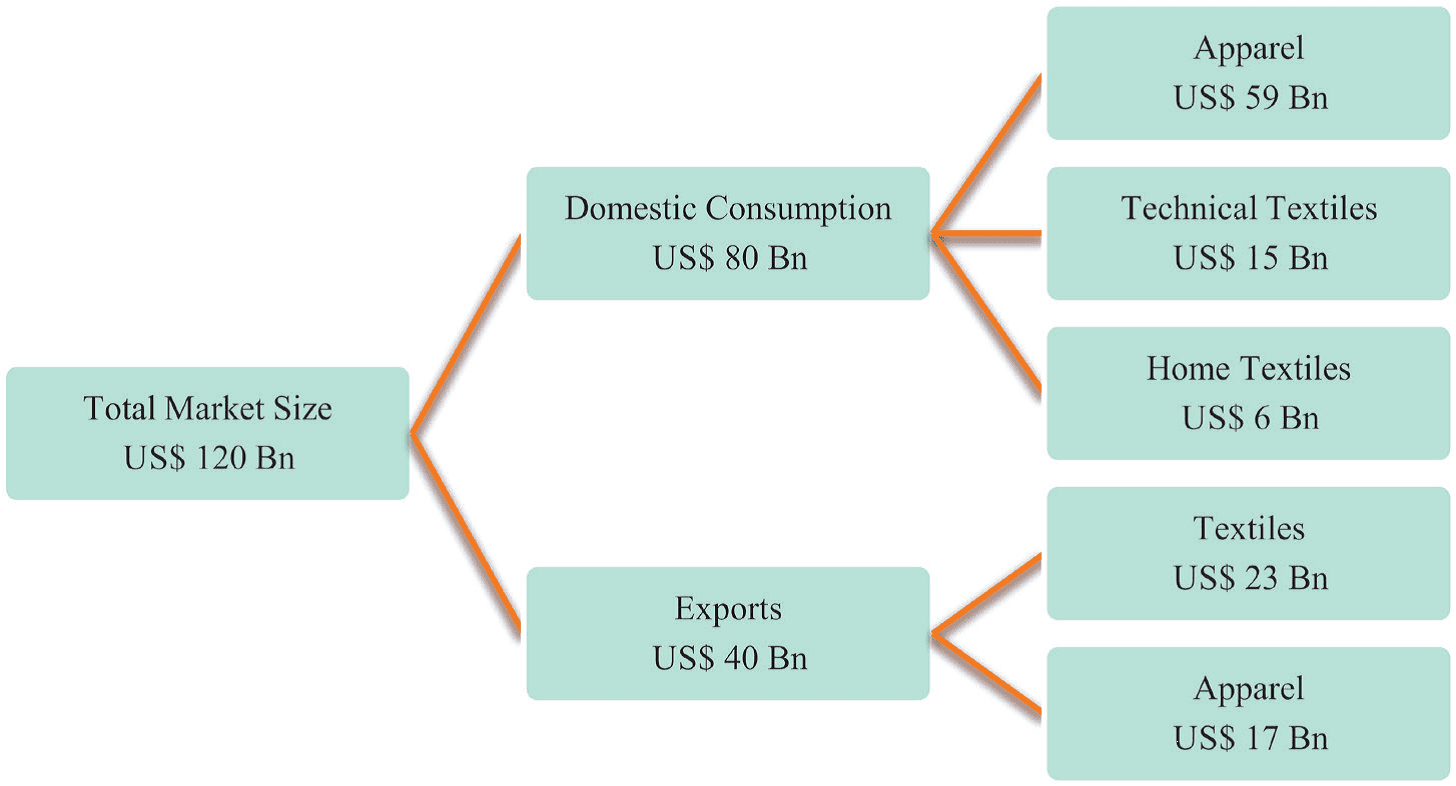

India is the second largest manufacturer of textile and apparel in the world, next to China. Indian

Textile and apparel market is estimated at US$ 120 Bn. The domestic consumption of textiles and apparel constitutes 65% of the total market size while exports constitute the rest 35%.

India’s Textile and Apparel Market Break-up

Table-7 (Source: DGCI&S and Wazir Analysis)

Table -7, Source -Wazir Advisors -Texcon 2016 – Theme Paper

Global Competitiveness& Trade Growth Paradigms for Indian Textile & Apparel Sector,13&14, October,2016, New Delhi, Wazir Advisors & Confederation of Indian Industries

Domestic Market Overview

The domestic consumption of US$ 80 bn. constitutes of Apparel (US$ 59 bn.), Technical Textiles (US$15 bn.) and Home Textiles (US$ 6 bn.). From 2000 to 2015, the overall consumption has grown at a healthy 11% CAGR.

Table -8, Source: Technotex 2011, Mumbai, India – Knowledge Paper, Enabling Framework for accelerating growth and investments in Technical Textiles in India

Technical Textiles with Application for Defence

Project concept

To setup a manufacturing unit of technical textile – Defencetech/ Protechproducts and its application in defence sector, based on the growing demand and easy availability of raw materials, infrastructure, and established supply chain setup in Gujarat.

What is technical textile for Defence?

Technical textiles that are used in the defence sector are called ‘Defencetech’. These are speciality textiles that provide safety to the wearer during high-risk engagements like protection from bullets and explosions, and also from extreme atmospheric conditions

‘Defencetech’ primarily forms a part of Protech (protective clothing) and also consists of some products of Sportech (technical textiles used for sports purposes) and Buildtech (construction textile components and fabrics used in building and construction industry).

The Ministry of Defence (Government of India) is one of the major consumers of Defencetech for the use of armed forces.

What comprises Defencetech?

Bullet proof jackets, High altitude clothing, Tarpaulins, Tents, Nuclear Biological & Chemical suits, Sleeping bags.

Source: Technical Textiles with Application for Defence, Textiles, Government of Gujarat, Vibrant Gujarat, 2017.

The Vision for Indian Technical Textiles

- To increase our Technical Textile manufacturing to Rs. 5.2 lakh crore by 2025

- Target exports of Rs. 1.3 lakh crore by 2025

- Become the preferred global Technical Textile manufacturing destination with focus on export oriented manufacturing specializing in high value added Technical Textile manufacturing, targeting the industrial and end user consumer segments

Key requirements

- Focus on increasing manufacturing capabilities – both capacity & Technology

- Focus on higher value add & product quality

- Ensuring skilled labour for high efficiency & quality

- Promoting exports

- Increasing the domestic retail & institutional consumer base

Source: Indian Technical Textile Industry: Current Scenario & Opportunities Sep 2016, Mumbai, iMacs, Techtextil, India

Conclusions

There is a bright future both Indian and Global Technical Textile Industry. Government of Gujarat is also focusing Technical Textiles with Application for Defence. It is a very positive opportunity for Technical Textile Industry in Daman, Valsad & Dadra Nagar Haveli (DVD).

Overall, market drivers of Technical Textiles include -Global population growth, Replacement of conventional building materials, increasing complexity of industrial production, Expansion of healthcare,

Growth in vehicle production, Growth in expenditure on sport and leisure products and Permanent opening up of new areas of application.

Centers of Excellence set up by Ministry of Textiles on Technical Textiles and Government’s Initiatives in Technical Textiles would give support research and development as well as innovations.

In the Textile Manufacture, the share of Technical Textiles would continue to grow.

Focus sectors of Make in India – Infrastructure, Energy & Defence Aviation & Space

Consumer goods & Service sectors as well as Pharma & Chemicals would give a boost for Technical Textile Sector.

References

- Indian Technical Textile Industry: Current Scenario & Opportunities, Techtextil, India Symposium 08, September, 2016 by ICRA Management Consulting Services Limited (Table – 1& 2).

- Centre of Excellence in Technical Textiles in India (Table -3).

- Table – 4, Source: OTxC – Baseline report 2012-13, IMaCS Analysis, Indian Technical Textile Industry: Current Scenario & Opportunities, Techtextil, India Symposium 08, September, 2016 by ICRA Management Consulting Services Limited (Table -4).

- Seshadri Ramkumar, TexSnips, July 3, 2013, Technical Textiles Creating Value for Spunbond Nonwovens, Presented at: THE SOUHTERN GUJARAT CHAMBER OF COMMERCE & INDUSTRY, SURAT, INDIA MARCH 24, 2014(Table -5).

- IFAI Specialty Fabrics Review, February 2012 and Transparency Market Research, USA, July 5, 2013, Technical Textiles Creating Value for Spunbond Nonwovens, Presented at: THE SOUHTERN GUJARAT CHAMBER OF COMMERCE & INDUSTRY, SURAT, INDIA MARCH 24, 2014(Table -6).

- Wazir Advisors -Texcon 2016 – Theme Paper ,Global Competitiveness& Trade Growth Paradigms for Indian Textile & Apparel Sector,13&14, October,2016, New Delhi, Wazir Advisors & Confederation of Indian Industries (Table -7).

- Technotex 2011, Mumbai, India – Knowledge Paper, Enabling Framework for accelerating growth and investments in Technical Textiles in India (Table -8).