Introduction:

The textile industry is the one of the largest industries in world in terms of output, production and employee. Mostly the textile industry is consisting of fibers, yarn, cloths, various chemicals. The raw material used in textile industry be natural, or synthetic using products of the chemical industry. The textile manufacturing process is characterised by the high consumption of various resources like water, fuel, and variety of chemicals used in long process sequence that generates a significant amount of waste. the issues are in terms of the environment or they may be in terms of the sustainability. The main environmental problem associating with textile industry is with water and emission of the air like, notably volatile organic compounds (voc)’s and excessive noise and odour also workspace safety.so the textile industries are facing various issues.

Issues in Textile Industry:

- High Noise level:

Noise has been accepted to the major threat to workers or employees in textile industry. Noise is the unwanted sound which interfere in the various functions of the textile industry. Noise is the disturbing sound irrespective of its duration and intensity. The humans are able to hear the sound up to 130 decibels. The sounds are mainly cause by machine gearings. So, there should be low noise level is required in textile industry.

The air suction and the compression are the primary reason of the noise pollution. The gearing of the machines i.e. Transmission of the motion creates the high noise level in the textile industry. In carding due higher speed of the licker in causes high noise levels. In draw frame due to high speed, drafting system, can change mechanism creates high noise. In conventional speed frame due to differential motion, building mechanism creates high noise. In weavings due to shedding motion, picking motion, beat up and extra loom attachment like pirn changing mechanism, drop box motion creates high noise level in textile industry. This are the main causes of creating high noise level in textile industry. Followings are standards for the noise level in textile industry (by M K Talukdar In Indian Journal of Fibre & Textile Research, March June 2001, Pp: 44-49).

| Sr. No | Section | Noise level (in dba) |

| 1 | Blowroom | 80-83 |

| 2 | Carding | 84-89 |

| 3 | Draw frames | 84-88 |

| 4 | Speed frame | 82-86 |

| 5 | Ringframe | 86-90 |

| 6 | Winding | 82-86 |

| 7 | Warping | 80-86 |

| 8 | Sizing | 73-86 |

| 9 | Non-auto loom | 94-99 |

| 10 | Auto loom | 95-97 |

So, the effects of the noise pollution. The noise pollution has directly impact on the workers. The noise level up to 80 dba causes the physiological effect and from 90-100 dba it effects the permanent damage to person’s hearing. The workers or employees reduces the ability to concentrate. There is disturbance of sleep. Oral communication is difficult or impossible during working. Due to high noise level the blood pressure increases, heart frequency increases, and effect on metabolism. So, noise level in textile industry should be reduce. To reduce the noise level in textile industry the standards are to be followed. Some special gears are should to be used in textile industry for reducing noise level e.g. Plastic gears.

- Exposure to toxic materials:

The textile industry is one of the higher polluting industry in the world in terms of exposure to toxic materials. The air and water are the most ways to expose the toxic materials. thousands of workers are engaged in textile industry. The textile industry involves various types of dyes and chemicals. After weaving there are so many processes are involved in textile industries.

In singeing the floating fibers are removed by burning so there will be chances of mixing the various gases in the atmospheric air.in desizing the size paste of the fabric by various chemicals like NaOH. After desizing, fabric still remain natural impurities these impurities are removed by hot alkaline solution. There many types of dyes are used. Dye is the most process which expose more toxic material and there are many acids, ionic compounds, alkaline solutions, enzymes are used for dyeing. In finishing the various chemicals are used to increase the lustre of fabric. So, this are the process which are directly depend on the chemicals and these chemicals are directly mixed with water.so the exposure to toxic materials is the one of the main issues of textile industry.

| UNIT PROCESS | POSSIBLE POLLUTANTS IN WATER | NATURE OF WASTE WATER |

| DESIZING | Starch, Glucose, CMC, PVA, Resin, Fats and Waxes | High BOD (35-50% of total) |

| SCOURING | NaOH, wax, grease, Na2CO3 | Strongly alkaline

High BOD (30% of total) |

| BLEACHING | Cl2, NaOH, H2O2, acid etc | Alkaline 5% of total bod |

| MERCERISATION | NaOH | Strongly coloured low BOD (less than 1%) |

| DYEING | Various dyes, acid, alkali, salts soaps, detergents. | Strongly coloured fairly BOD (less than 6%) |

| PRINTING | Colour, starch, china clay, acid, alkali, and various metallic salts. | Highly coloured and oily appearance BOD (6-10% of total) |

| FINISHING | Trace of starch, tallow and finishing agent | Low BOD (2-4% of total) |

The effect of the toxic material exposure. This reactive are used for finishing, dyeing and printing purpose. The solvents used in this industry creates different health related hazards including cancer. Due to exposure of toxic material in water.it creates water pollution. Some of this water borne diseases are typhoid, cholera, jaundice, fever etc. Due to exposure of toxic material in atmospherically air creates air pollution. Air pollution include heart deceases, lung cancer, respiratory deceases to the workers. Also, long term damage to the workers such as nerves, brain. Bad smell is mixing with air in the time of chemicals processing so there will be reduces the ability of the workers.

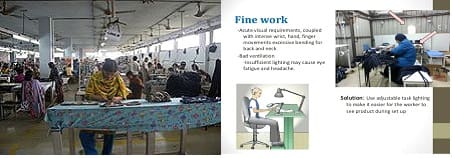

- Ergonomic condition:

Ergonomic condition means the relation between workers and their environments. It is study to improve the workstation and focus on current condition of work. There are two major objectives of the ergonomics. To enhance the effectiveness and efficiency of the working is the first objective. To enhance certain desirable human values. The ergonomics plays very important role in textile industry as well as all other industries. The human values are consisting of workers safety, reduces fatigue, reduces stress, increased comfort, job satisfaction, improving quality of life. If industry will not care about the ergonomic then it directly impacts on the productivity and efficiency of the machine or industry.so the industry is must care about the ergonomic. The ergonomic mostly facing the apparel industries.so the companies are trying to improve their ergonomic conditions. So, they can improve the productivity and safety. Reduces worker compensation costs. Provide more reliable workforce. This all condition is handled by the HR and IR. So, the ergonomic condition is one of the main issue in textile industry for workers.

- Cotton dust:

Cotton dust is the one of the major issue I textile industry. Mainly cotton dust is the flying of the cotton fiber in the industry. The cotton dust is mainly coming from the spinning industry. In spinning the material flow is from the suction duct so there will be chances of mixing the cotton fiber in the free air. In blow room due to half beating point, the material is opened I the free air so there will be more chances of fly generation. After blow room, the chances are in the drafting system. Due to high speed drafting there will be chances of fly generation. In twisting zone, due to high speed of the spindles there will be chances of fly generation. The moisture is also most important parameter in the fly generation. If the moisture in fiber is too low then they are trying to fly due to reducing in the weight. So, this are the parameters due to which the fly generation i.e. cotton dust is increases in spinning industry.

The effects of the cotton dust. Due to high fly generation the quality of the output is reduces because the cotton dust mainly consists of the short fiber. So, this short fibers are trying to mix with the various outputs. Mainly this causes the quality of the yarn. In twisting the fly generation is more so this short fiber are trying to mix with the yarn in twisting, so there will be chances of breakages. Another effect of the cotton dust is breathing problem. The dust is very light weight so the fiber are go in respiratory system so due to this the breathing problems are occurring to the workers.

Waste in industry:

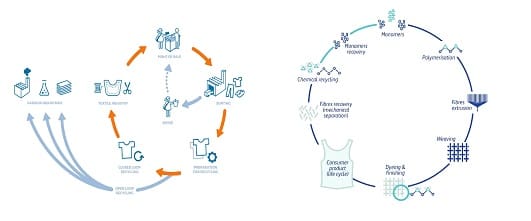

The textile waste contains fashion and textile industry waste. The textile waste is the recyclable waste. Textile industry is one of the high wasting industry in the world. There are many types of waste are exposed by textile industry. The materials are recycled in terms of the yarns, floor mats, prayer rugs, blankets and beds. The textile waste is generally classified as pre consumer waste and post-consumer waste. The pre consumer waste is consist of by product material to apparel industry and the post-consumer waste is consist of originates from household resources. The post-consumer waste is recycled as it is used as embroidery purpose.

In spinning there are waste like fiber and the yarn. The fiber waste are collected and bales are formed. These bales are transported in various industries and used for non-woven purpose i.e. felted cloths are formed. Some of the fibers are used for fashion purpose. So, waste management is the one of the important issues for the textile industry. The following is the flow chart for textile waste management (By Ramesh Narkhedkar, A. Patange, C. Patil in Asian Textile Journal, January 2018).

In spinning there are waste like fiber and the yarn. The fiber waste are collected and bales are formed. These bales are transported in various industries and used for non-woven purpose i.e. felted cloths are formed. Some of the fibers are used for fashion purpose. So, waste management is the one of the important issues for the textile industry. The following is the flow chart for textile waste management (By Ramesh Narkhedkar, A. Patange, C. Patil in Asian Textile Journal, January 2018).

- Environmental Issues:

The environmental pollution is the one of the important issues in the todays world especially by the industries. Tremendous globalisation is going on in the sector of the textile industry. So, there will be increase in the environmental pollution. The textile industries mostly create all types of pollutions like air, water, noise, and the soil pollution also. In processing the various gases are mixed in the atmosphere such as CO2, Volatile Organic Compounds (VOCs), etc. this VOCs can be the glycol ethers, detergents and the combustion gases. Due to these gases there will be effect on direct ozone layer. In water pollution, there will be releasing the various dyes, acids, alkalis and compounds directly in the water. In the world the 20% of fresh water pollution is created by textile industries. So, water pollution effects in the rural region. In soil pollution, there are many fashionable cloths are thrown on the soil after using. So, the cloths are may be made by natural fibers or the man made fibers. If natural fiber are used the they are biodegradable but the man-made fibers like polyester, nylon are not biodegradable. So, they take many years to degrade in the soil. So, the environment is one of the main issues in the textile industry.

Atmospheric Conditions:

Atmospheric Conditions:

The textile industry is the industry which affects on the environmental condition. The textile industry is totally depending on the environmental condition. In various process of the textile the inner and outer atmosphere plays important role. In spinning the quality of the yarn is totally depend on the relative humidity. Specially the yarn spun in the humid temperature. So, if the outer atmosphere changes the there will be effect on the relative humidity and temperature of the industry. Hence it is very difficult to maintain constant humidity and temperature in the industry especially in rainy season.in ring frame, if the relative humidity changes there will chances of breaking the yarn also the fibers are difficult to spun. Due to this the efficiency of the department reduces and the work load increases on the workers.in weaving, if there will be change in the relative humidity then end breakages are occurred. So, the quality of the fabric is also reduced because of the end breakages. In weaving every stoppage of the machine includes one defect in the fabric. So, if the environment changes the quality of the product is also changes.

- Breathing problems:

This problem is especially faced by the workers. In spinning there will be the cotton dust which creates the breathing problem to the works. In processing, due to the smelling of the various acids, bases and compound. They are consisting of very bad smell. Due to this there will be chances of breathing problem to the workers. And there will be permanent damages on the respiratory system on

the workers. So, the workers should be taking care about it. They should have to use the mass. And company also should have to provide the nose mass to the workers. The many workers are facing these breathing problems. Due to this they should not able to the concentrate on the work. So, it is also issue for the textile industry.

References:

- K. Talukdar, “Noise Pollution and Its Control in Textile Industry”, Indian Journal of Fibre & Textile Research Vol. 26, March-June 2001, Pp. 44-49.

- S.S. Jayawardhana, M.Y.A. Perera, G.H.D. Wijesena, “Analysis and Control of Noise in Textile Factory”, International Journal of Scientific and Research Publication, Vol. 4, Issue 12, December 2014.

- Narkhedkar, A. Patange, C. Patil, “Textile Waste Management of Natural Fibers”, Asian Textile Journal, January 2018, Pp. 43-46.

- Tim smalley (2016): 4’c of marketing. Accessed on 6/5/19 Retrieved from: https://www.stratomic.uk/blog/what-are-the-4cs-of-marketing/

- Bickle, M.C., (2010): Fashion marketing instructor’s guide. Accessed on 12/5/19 Retrieved from http://media.bloomsbury.com/rep/files/Bickle_IG.pdf

- V (2017): Fashion retailing, marketing, and merchandising. Accessed on 12/5/19 Retrieved from https://www.britannica.com/art/fashion-industry/Fashion-retailing-marketing-and-merchandising

- Shaikat, N.M., (2018): Future Challenges of Apparel Industry. Accessed on 16/5/19. Retrived from http://ordnur.com/apparel/10-future-challenges-of-apparel-industry/

- M., (Apr 2019): Industry suffers as chemical units shut in China, Accessed on 20/7/19 . Retrieved from http://www.caionline.in/articles/industry-suffers-as-chemical-units-shut-in-china

- Y. (2018): Fast fashion: Good for business, bad for the planet. What can you do? Accessed on 21/7/19. Retrieved from https://www.globalsources.com/NEWS/SIC-fast-fashion-good-business-bad-planet-can.HTM

- C., (June 2016): Challenges for fashion retail in India. Accessed on 27/7/19. Retrieved from https://www.indiaretailing.com/2016/06/20/fashion/challenges-fashion-retail-india/

- S., (May 2019): From Opulence to Sustainability, Indian Fashion Gets Redesigned. Accessed on 29/7/19. Retrieved from https://thewire.in/culture/from-opulence-to-sustainability-indian-fashion-gets-redesigned