Prof. V K Batra and Mrs. Parvin Batra, Global Competence, Panipat.

Located on the NH.1 at about 90 K.M. from New Delhi towards Amritsar, lies Panipat- a leading name in home textiles nationally & globally for bed linens, carpets, kitchen linens, bathmats, cushions and other textile articles.

During the partition in 1947, a large number of professional weavers from Sindh, Jhang and Multan (now in Pakistan), migrated to India and set up their looms and got busy in their ancestral craft of weaving durries. Panipat is one of the largest markets of raw wool in northern India. Today the Panipat- Ambala durrie-rug belt, from cotton to woollen durries, is famous all over the country and has various outlets at home and abroad.

Handloom Sector

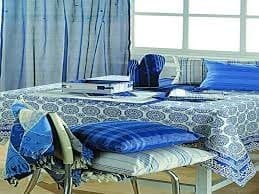

Panipat is famous for the largest and most well-functioning Handloom Entrepreneurs, producing international quality of hand-woven rugs, carpets and other floor coverings and handloom made bed sheets and cushions curtains, table covers, kitchen and bath linen made of Handloom cloth in a large quantity in Northern India. .

There has been a steady growth in the handloom sector of Panipat during the last 45 years. At present, there are more than 25000 handlooms working in the district providing employment to about 60,000 people. A majority of the weavers are migrants from U.P, Bihar and West Bengal. There are some local weavers also who have come from the neighbouring villages to work in the handloom units of Panipat. There is demand of traditional Handloom products in the International Market, which is helping to keep this sector dynamically alive.

Cluster Profile of Panipat.

The textile Cluster of Panipat is concentrated in and around Panipat City and its sub urban villages. The industry comprises of seven segments i.e. handloom, woollen carpets, shoddy yarn spinning, power-loom industry, wet processing and hosiery woollen yarn industry. The cumulative turnover of all these units is estimated at Rs. 11,000 crores and provides employment to more 75,000 persons.

Technology & R&D: The cluster players have exhibited keen interest towards technological upgradation. Consequently, a large number of units operate on latest equipments and machines. Their focus is to respond to the buyers needs and satisfaction on all aspects of product and services.

Raw Material: The industry producers have yet another advantage when it comes to raw materials used in the manufacturing process. This is especially because, along with well skilled labor, the sector is assisted with strong raw material base.

Products & Markets

Thanks to its wide range of products, the Handloom Home textiles manufacturers from Panipat enjoy huge customer database. Their product range includes carpets & floor coverings, bed & bath linen, kitchen & table linen, home furnishing fabrics, fully furnished madeups and decorative textiles. There is good potential in the domestic market for the traditional rugs, Carpets, Durries, Bed sheets and other Handloom Products.

Domestic Market. Many Exporter Manufacturers perceive a huge potential and better margins in the domestic market due to the increased buying capacity of the middle class and are trying to capitalize on it. For eg. Mahajan Overseas launched Maspar in 2002. It has established 11 exclusive outlets in 6 cities, is present through shop in shops in major departmental stores in India. Other player Golden Terry Towels supplies terry towels & blankets under its brand ‘Golden Terry’.

But there are many who manufacture exclusively for domestic market do not find exports very rewarding expect for some items.

International Market:

The Panipat home textile industry has now grown to the extent that it earns a turnover of nearly Rs. 4200 crore per annum from exports. The Exports Industry consists of four main Tiers

- Large Scale Manufacturers and Merchant Exporters

- Medium Scale Manufacturers and Merchant Exporters

- Small Scale Manufacturers and Merchant Exporters

- Micro Scale Manufacturers & Fabricators for Exporters

The reason for sustenance of Panipat in exports is its capability to customise the products as per customer demands. The exporters now give priority to designing and R&D which now comes under the separate cost head as they have come to know that innovation is key to success in this evolving consumers lifestyle trends. Understanding the importance of product diversification and demands some exporters have entered into accessories like throws, chair covers and pads, poufs and are planning to exports other diversified textile products. The easy availability of raw materials and economies of scale leading to low cost of production are the major factors which have led to the development of Panipat as a major production and export hub for home textiles. It has also developed as a sourcing hub for raw material for home textiles. As reported by some exporters- manufacturers home textile business is growing at the rate of 20 – 25% every year. It has made home fashion a commodity.

Europe and USA are the two major markets for Panipat Exporters, accounting from 50% to 95% of their exports. Some players have also started selling their goods to Latin America, Australia, Japan, Middle east and other countries. Many leading brands and retailers like Wal-Mart, JC Penny, Sears, Springs, Lafayette, Target and many more, the list is long, source home textiles from Panipat. Some of the major players in home textile market of Panipat are Masper Overseas Ltd & Mahajan Overseas, Raj Overseas, Handfab Home, Paliwal group, Dream Home Carpets (Jainsons Exports),Rivera Home Furnishings, Golden Terry Towels, Devgiri Group, Javi Homes and the likes exporting in hundreds of crores.

Power loom

The Power-loom sector is the largest amongst all, most of the powerlooms are attached with Jacquard for creating a wide range of designs on bed covers, curtains, upholstery, blankets etc. There is also an addition of 900 new and second hand shuttle-less looms in this sector to sustain the market competition. The power-loom products are mainly for the domestic market. Art silk, polyester, acrylic and polypropylene, and shoddy yarn are the main raw materials of this sector. The Shoddy yarn is available from the local Shoddy spinning units and the synthetic yarns are sourced through local traders. Power loom sector provides employment to 15,000 people in Panipat Cluster.

Carpet Industry

It is a labour oriented industry and workers from nearby villages come to Panipat to work in the carpet units. There are mainly two types of carpets manufactured in Panipat- Hand tufted carpet and Handloom carpet. The hand tufted carpets of the district stand at the top position in the overall carpet production in India. Panipat is also famous for its woollen tufted carpet and it even caters to the international market. The raw material for this is sourced from New Zealand, Bikaner, Jodhpur and Jammu & Kashmir.

Shoddy and Woollen Industry

The shoddy industry has picked up sharply in Panipat during the last 15 years. The cheap blankets produced out of these have replaced the previously used thick cotton fabric i.e. Khes. The woollen yarn manufactured is used in hosiery and carpet industry.

Open End Rotor Spinning

There are about 45 open-end spinning units in Panipat. This sector caters the needs of weavers of handloom & power loom units of Panipat, U.P and Rajasthan. A unique feature of this type of spinning is that it uses upto 85% of waste cotton to spin cotton yarn. The cotton yarn so produced is used in manufacturing mainly exportable items of handloom.

Processing Units

There are about 150 dyeing and printing units, and about 35 finishing units in the district to meet out the requirement of the local textile industry. Most of the units are equipped with locally made yarn.

Techno-Managerial Manpower: The home textile industry has a definite gap of professional manpower. Professional manpower required is techno managerial. There are very few techno managerial institutes in India like SVPITM, NIFT, ATDC, ALT etc. and none of these has any presence in Panipat. Manpower training in skill development at shop floor level & Managerial skills at middle and upper level management is done on adhoc basis. Whatever skills these people develop are experience based, therefore these skills have huge gaps. These skill gaps have already been identified in Textile Industry, Furnishing Industry & Retail Sector by NSDC.

The Problem exists at two levels.

- Lack of awareness at the part of the man power as well as entrepreneurs who are manufacturers, exporters, traders and retailers.

- The demand supply gap being too high they have no choice but to accept the man power as it comes.

Moreover the cut throat competition at the local, national & international level, the trained manpower keeps on shifting from the lower turnover company to higher turnover company because of close interaction of the cluster. Therefore it is recommended that institutes on these lines be opened in Panipat to provide better equipped man power.

Initiatives by State & Central Governments

Inspite of remarkable export and domestic performance and generation of high employment by the Panipat industry both state & central government have to do a lot for the improvement of the infrastructure in Panipat which still has a high potential. State and Central Government intervention is required in modernisation of Weavers Service Centre. Recently the Ministry of MSME has sanctioned a Common Facility Centre project of Rs.20 Crores with a grant of about Rs.15 Crores.

Still a good rapport is required between the entrepreneurial groups of Panipat and The Govt. To upgrade the infrastructure and facilities possible under the various schemes of cluster and skills development.

.

.