As someone who has straightened their hair clearly knows, water is the enemy. Carefully straightened hair by heat will bounce back into waves the minute it comes in contact with water. Since the hair has knowledge of shape. Its material properties allow it to change shape in response to some stimuli and in response to others, to revert to its original form.

What if other materials, especially textiles, had memory of their shape? Imagine a T-shirt that opened with ventilation vents when exposed to moisture and closed when dry, or one-size-fits-all clothing that expands or shrinks to dimensions of an individual.

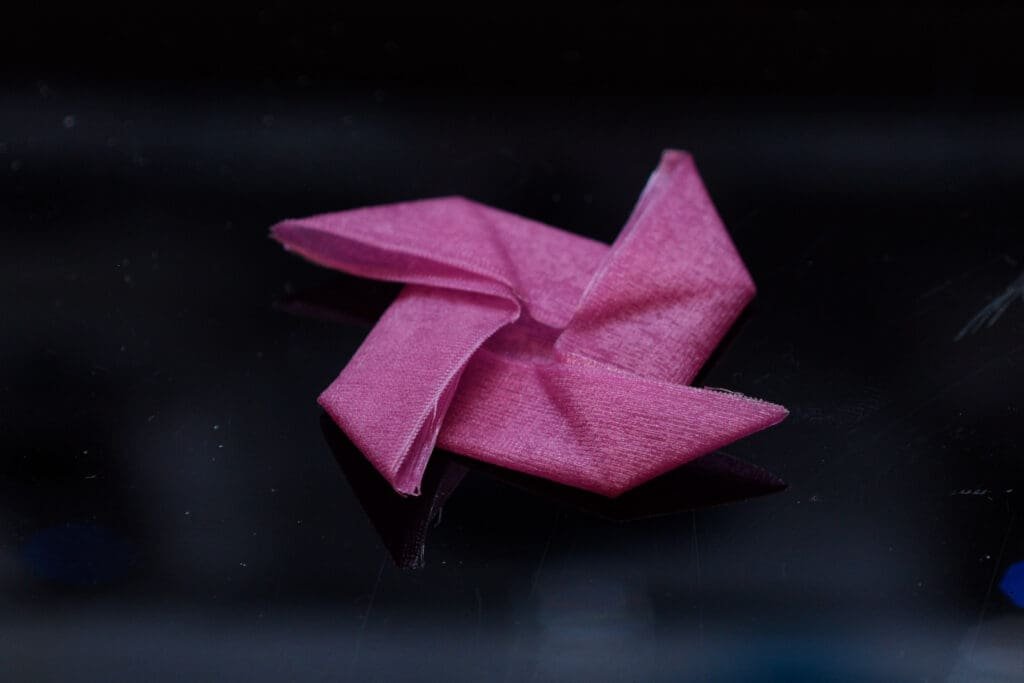

Researchers at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) have now created a biocompatible substance that can be 3D-printed into any shape and pre-programmed with reversible form memory. Keratin, a fibrous protein present in hair, nails, and shells, is used to produce the material. The researchers removed the keratin from the residual Agora wool that was used in textile processing.

The research could support the initiative to minimise waste in the fashion industry, one of the planet ‘s largest polluters. Designers like Stella McCartney are now reimagining how fabrics, like wool, are used in manufacturing. The substance may have medicinal applications, too.

“With this project, we have shown that not only can we recycle wool but we can build things out of the recycled wool that have never been imagined before,” said Kit Parker, the Tarr Family Professor of Bioengineering and Applied Physics at SEAS and senior author of the paper on the subject published in Nature Materials. “The implications for the sustainability of natural resources are clear. With recycled keratin protein, we can do just as much, or more, than what has been done by shearing animals to date and, in doing so, reduce the environmental impact of the textile and fashion industry.”

The key to the shape shift capability of keratin is its hierarchical structure, said Luca Cera, a postdoctoral fellow at SEAS and the paper’s first reviewer. It arranges a single keratin chain into a spring-like structure known as alpha-helix. Two of these chains curl together to form a coiled spiral shape. Many of these are formed into protofilaments and finally large fibres.

“The organization of the alpha helix and the connective chemical bonds give the material both strength and shape memory,” said Cera.

When a fiber is stretched or exposed to a particular stimulus, the spring-like structures uncoil, and the bonds realign to form stable beta-sheets. The fiber remains in that position until it is triggered to coil back into its original shape.

“Whether you are using fibers like this to make brassieres whose cup size and shape can be customized every day, or you are trying to make actuating textiles for medical therapeutics, the possibilities of Luca’s work are broad and exciting,” said Parker. “We are continuing to reimagine textiles by using biological molecules as engineering substrates like they have never been used before.”

SOURCE: The Harvard Gazette