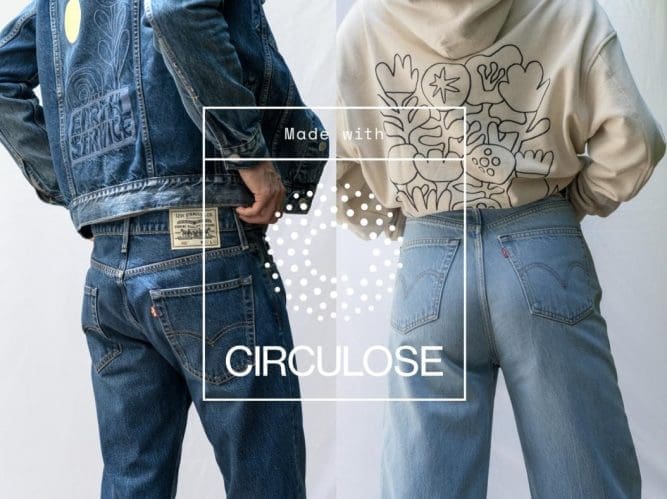

This week, the Levi’s® brand launched its most sustainable jean ever, a garment made with organic cotton and Circulose®, a breakthrough material made in part from worn-out jeans. Available through the Levi’s® Wellthread™ line in the 502 for men and High Loose for women, this jean represents more than five years of research in circular denim design.

This unique collaboration between Wellthread™ and re:newcell, the innovators behind Circulose®, marks a significant milestone in the fashion industry’s transition to circularity. Here, Una Murphy, Levi’s Senior Designer for Innovation, talks about how these garments came about and what they mean to us and the industry:

What are these jeans?

These jeans represent an important step in our journey to reduce the environmental impact of our products and keep garments out of landfills.

Part of the DNA of Levi’s® is to create garments that last for decades, and these jeans prove that we also now have the capability to regenerate old jeans into new raw materials

By using high quality recycled denim, we save on the water, chemical and CO2 footprint of our jeans. Each part of the jean – the trims, the thread, etc. – are carefully calibrated to ensure it meets recycling specifications, allowing it to have a second life when it’s worn out. We’ve worked with our innovation partner, re:newcell, to ensure the jeans can go back into their system and be used to make new raw materials, demonstrating that this garment is fully recyclable and truly circular.

In addition, we’re always seeking ways to reduce our water footprint and these jeans save water at every step of their creation, including the fiber stage with organic cotton and Circulose®, which consists of sustainably sourced viscose comprised of 50 percent recycled content from old jeans. We also utilize a water-saving dye method for our denim and each garment uses our Water<less™ garment finishing practices.

How did the collaboration with re:newcell come about?

As part of our ongoing effort to reduce the impact of our source materials, we have long been investigating and innovating new fiber and fabric strategies that we believe can deliver more sustainable products. And the Wellthread™ line has given us the opportunity to build a sustainable design practice through which we can substantiate these innovations, determining if they work and if they can scale.

We’ve always followed a design methodology driven towards greater circularity and that led us to re:newcell. In 2018, we visited their facility in Sweden, and seeing their environmentally friendly pulping process solidified our commitment to working with them. When the partnership afforded us the opportunity to use some of their first commercially available fiber, our Wellthread team mobilized to bring the product to market.

Why do we think this is important/notable?

The fashion industry consumes a huge amount of virgin fibers – an estimate from a few years back put the number at 53 million tons. Cotton was around a quarter of that amount, and about three-quarters of it eventually wound up in landfill or was burned. This wasteful approach to overconsumption and use of natural resources is far from sustainable.

In our ongoing research and development, we strive to improve our design practices and conserve environmental resources every way we can. By incorporating sustainable innovation, we learn what’s possible and work towards solving some of our biggest challenges. These jeans are a realization of a vision and a more circular design practice that can keep materials in circulation longer, therefore reducing the impact of the garments we create, while still delivering the same style and longevity Levi’s® are known for.