- Glass fibre is a special type of synthetic fibre.

- It is also known as fibre glass that is a material consisting of numerous extremely fine fibres of glass.

- It is very strong fibre. The versatility of glass as a fibre makes it unique industrial textile material.

- Glass fibre in fabric form offers an excellent combination of properties from high strength to fire resistance.

RAW MATERIALS:

- Glass fibers can also occur naturally, as Pele’s hair. Pele’s hair is a form of lava. It is named after Pele, the Hawaiian goddess of volcanoes. It can be defined as volcanic glass fibers or thin strands of volcanic glass. The strands are formed through the stretching of molten basaltic glass from lava.

- Pele’s hair is extremely light, so the wind often carries the fibers high into the air and to places several kilometers away from the vent. It is common to find fibers of Pele’s hair on high places like top of trees, radio antennas, and electric poles.

Pele’s Hair

Pele’s Hair

- Pure silica (silicon dioxide), when cooled as fused quartz into a glass with no true melting point, can be used as a glass fiber.

Silica

Silica

Fused Quartz

Fused Quartz

COMPOSITIONS AND THEIR FUNCTIONS:

-

- Silica or silicon dioxide: obtained from sand or sandstones

- Lime, Magnesium oxide: used as stabilizing agent

- Alumina: used for stretch, durability and resistance to weathering

- Zinc oxide: used for acid durability

- Titanium dioxide: reduces viscosity in the spin bath

- Barium oxide: increases the rate of melting

- Boron oxide: increase the difference between temperatures

| TYPES OF FIBRE GLASS | COMPONENT | USES | PROPERTIES | |

| E- GLASS (Electrical) | Alumino-borosilicate | 1% alkali oxide | Glass Reinforced Plastics (GRF) | Continuous filament |

| A-glass (Alkali glass) | Alkaline-lime | Little or no boron | Cullet glass | |

| E-CR Glass (Electrical/Chemical Resistance) | Alumino-lime silicate | Less than 1 % alkali oxide | high acid resistance

Does not melt but softens |

|

| C- glass (Chemical resistance ) | Alkali-lime | High boron oxide | Staple fibers and insulation | Chemical resistance |

| D-glass (Low Dielectric glass ) | borosilicate | Low dielectric constant | ||

| R- glass (Reinforcement ) | Alumino silicate | No MgO and CaO | reinforcement | High mechanical req. |

| S- glass (Strength ) | Alumino silicate | High MgO and CaO | Building and aircraft | High tensile strength |

| T-glass (type of C glass ) | Type of C-glass | Insulation and blown fibreglass | Resistant to chemical attack |

Cullet Glass

E-Glass

E-Glass

GLASS FIBERS PROCESSING:

- Textile-grade glass fibers are made from silica (SiO2) sand, which melts at 1720°C. SiO2 is also the basic element in quartz, a naturally occurring rock.

- Glass is produced by altering the temperature and cool down rates.

- If pure SiO2 is heated to 1720°C then cooled quickly, crystallization can be prevented and the process yields the amorphous or randomly ordered atomic structure we know as glass.

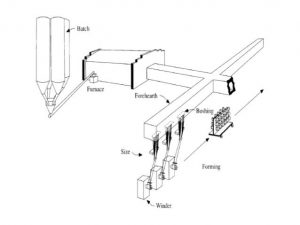

- This process can be broken down into five basic steps: batching, melting, fiberization, coating and drying/packaging.

1] Batching

- In the initial stage of glass manufacture, therefore, these materials must be carefully weighed in exact quantities and thoroughly mixed (batched).

- Although a viable commercial glass fiber can be made from silica alone, other ingredients are added to reduce the working temperature and impart other properties that are useful in specific applications.

- Along with other components, boron oxide is used to increase the difference between the temperatures at which the E-glass batch melts and at which it forms a crystalline structure to prevent clogging of the nozzles used in fiberization.

2] Melting

- From the batch house, another pneumatic conveyor sends the mixture to a high temperature natural gas-fired furnace for melting.

- The furnace is typically divided into three sections:

- The first section receives the batch, where melting occurs and uniformity is increased, including removal of bubbles.

- The molten glass then flows into the refiner, where its temperature is reduced.

- The final section is the fore hearth, beneath which is located a series of four to seven bushings that, in the next step, are used to extrude the molten glass into fibers.

Bushings

The industry takes three main approaches to glass melting:

(1) Indirect melt (also called marble remelt); for indirect marble remelt, molten glass is sheared and rolled into marbles which are cooled, packaged and then transported to a fiber manufacturing facility where they are remelted for fiberization.

(2) Direct melt using larger-scale furnaces (8,000 to 100,000 metric tonnes per year); and

(3) Direct melt using smaller-scale furnaces (150 to 200 metric tonnes per year), which are also called paramelters.

The direct melt process transfers molten glass in the furnace directly to fiber-forming equipment. Because direct melting eliminates the intermediate steps and the cost of forming marbles, it has become the most widely used method.

3] Fiberization

- Glass fiber formation, or fiberization, involves a combination of extrusion and attenuation.

- In extrusion, the molten glass passes out of the fore hearth through a bushing made of an erosion-resistant platinum/rhodium alloy with very fine orifices.

- Bushing plates are heated electronically, and their temperature is precisely controlled to maintain a constant glass viscosity.

- Water jets cool the filaments as they exit the bushing at roughly 1204ºC.

- Attenuation is the process of mechanically drawing the extruded streams of molten glass into fibrous elements called filaments.

- A high-speed winder catches the molten streams and, because it revolves at a circumferential speed of ~2 miles/~3 km per minute (much faster than the molten glass exits the bushings), tension is applied, drawing them into thin filaments.

- The bushings are expensive, and their nozzle design is critical to fiberization. Nozzle diameter determines filament diameter, and the nozzle quantity equals the number of ends.

4] Coating

- In the final stage, a chemical coating, or size, is applied.

- Size is typically added at 0.5 to 2.0 percent by weight and may include lubricants, binders and/or coupling agents.

- The lubricants help to protect the filaments from abrading and breaking as they are collected and wound into forming packages and, later, when they are processed by weavers or other converters into fabrics or other reinforcement forms.

- Coupling agents cause the fiber to have an affinity for a particular resin chemistry, improving resin wetout and strengthening the adhesive bond at the fiber-matrix interface.

- Some size chemistry are compatible only with polyester resin and some only with epoxy while others may be used with a variety of resins.

5] Drying/packaging

- Finally, the drawn, sized filaments are collected together into a bundle, forming a glass strand composed of 51 to 1,624 filaments.

- The strand is wound onto a drum into a forming package that resembles a spool of thread.

- The forming packages, still wet from water cooling and sizing, are then dried in an oven, and afterward they are ready to be palletized and shipped or further processed into chopped fiber, roving or yarn.

- Roving is a collection of strands with little or no twist.

- Yarn is made from one or more strands, which may be twisted to protect the integrity of the yarn during subsequent processing operations, such as weaving.

Glass fibres wound on the drum

Creeling Process

Creeling Process

MANUFACTURING:

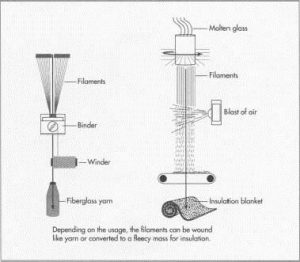

After the initial process of melting glass and passing it through spinnerets, continuous filaments or staple fibers of glass are manufactured by two different methods.

1] Continuous Filament Process

In this process, continuous filaments of indefinite length is produced. The molten glass passes through spinnerets having hundreds of small openings.

- These strands of multiple filaments are carried to winder revolving at very high speed of more than 2 miles per km.

- This process draws out the fibers in parallel filaments of the diameter of the openings.

- A sizing or a binder is applied to facilitate the twisting and winding process and to prevent breakage during yarn formation.

- After winding, filaments are further twisted and plied to make yarns by methods similar to those for making other continuous filament yarns.

- The sizing is removed in an oven. These yarns are used for making such items as curtains and drapes.

2] Staple Fiber Process

- The molten glass flows through the small holes of bushing, where jets of compressed air shake the thin streams of molten glass into fine fibers.

- These fibers vary in length ranging from 8 to 15 inches. The fibers fall through a spray of lubricant and a drying flame onto a revolving drum where they form into a thin web.

- These yarns are used for fabrics for industrial purposes where insulation is required.

- The staple fiber, if subjected to oven, is compressed to the desired thickness and the binder which was earlier applied, is cured. This permanently binds the fibers.

SPINNING:

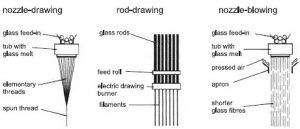

The subsequent manufacture of glass fibres may be executed to the direct melting process. However, in most cases glass rods or balls are made first which then may undergo a variety of further processes.

- Nozzle drawing- The glass fed in is melted in a heated melt tub at 1250–1400oC. Then, it emerges at the bottom of the melt tub from nozzle holes of 1–25 mm diameter and it is taken off and drawn. The filaments solidify and are finished and wound. One can find them in the shops as various kinds of “glass silk”. To make them into webs, the filaments are cut to length (mostly, between 6 and 25 mm).

- Nozzle blowing- The same as with nozzle-drawing, glass balls are melted in the tub. The melt emerging from the nozzle holes is then taken by pressed air, which draws the liquid glass so as to make fibres of 6–10 um diameter. A fluttering effect is caused by the flow of pressed air, which results in fibres of lengths from 50 to 300 mm. A lubricant is put on and the fibres are laid down on a sieve drum which sucks them in. The dry web received is held together by the long fibres, the short ones lying in between them as a filling material. Then, the slivers of glass fibre material are cut.

- Rod drawing- By means of a burner, bundles of glass rods are melted at their bottom ends. This results in drops which, as they fall down, draw filaments after them. The filaments are taken by a rotating drum, a squeegee laying them down onto a perforated belt. Thus, a dry web is received which can be wound as glass fibre slivers. Machine performance being limited by the number of glass rods fed in, the rotating drum may be combined with nozzle-drawing, which results in drum-drawing. This multiplies machine performance. The dry web is again laid down onto a perforated belt and solidified or, after winding it so as to receive slivers, cut for further processing on machines producing wet laid nonwovens. Using and processing glass fibres is not without any problems. For example, fine pieces of broken fibres may disturb if the work place is not well prepared for the purpose. Using the nonwovens to manufacture glass-fibre reinforced plastics, it is important the surface of the plastic material is fully even. Ends of fibre looking out may be pulled out or loosened by outward stress (temperature, gases, liquids), which may influence material characteristics. In some cases, it is advisable to cover up such layers of glass fibre with suitable chemical fibres.

PROPERTIES:

- Mechanical strength: Fiberglass has a specific resistance greater than steel. So, it is used to make high-performance fabrics

- Electrical characteristics: Fiberglass is a good electrical insulator even at low thickness.

- Incombustibility: Since fiberglass is a mineral material, it is naturally incombustible. It does not propagate or support a flame. It does not emit smoke or toxic products when exposed to heat.

- Dimensional stability: Fiberglass is not sensitive to variations in temperature. It has a low coefficient of linear expansion.

- Compatibility with organic matters: Fiberglass can have varying sizes and has the ability to combine with many synthetic resins and certain mineral matrices like cement.

- Non-rotting: Fiberglass does not rot and remains unaffected by the action of rodents and insects.

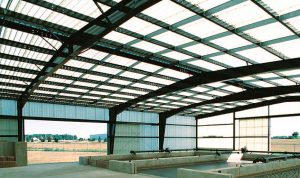

- Thermal conductivity: Fiberglass has low thermal conductivity making it highly useful in the building industry.

- Dielectric permeability: This property of fiberglass makes it suitable for electromagnetic windows.

USES:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FRP Tanks

Boat Hulls

Boat Hulls

Flame Proof Fabrics

Construction

Roofing Panels

Casts

BLENDS:

- Glass-reinforced plastic (GRP) is a composite material or fiber-reinforced plastic made of a plastic reinforced by fine glass commonly referred to as fiberglass.

- Reinforced concrete: Glass fibre concretes are mainly used in exterior building façade panels and as architectural precast concrete.

- Aramid-Glass: The high impact resistance and strength of aramid fiber combines with the good compressive and tensile strength of glass. The aramid glass laminate has also improved delaminating resistance.

Article written by Arwa Aamir Kalawadwala, M.Sc. in Textile and Fashion Technology, from College of Home Science, Nirmala Niketan. Textile Value Chain Intern.