Chaudhary S. and Raisinghani D.

Textile Manufactures Department.

Veermata Jijabai Technological Institute, Matunga, Mumbai- 400019.

ABSTRACT

Geotextiles in flexible forms have been used for infilling of various materials for number of applications. Some of the applications include i) sand filled geotextile bags for beach protection and erosion control, ii) Dredged silts and clays for dewatering harbour and river sediments and iii) separating polluted materials from harbour, river and industrial processes for the purposes of both dewatering and decontamination. Such Geotextile forms have been referred by various names such as Geotextile containers, Geobags, Geobags and so on. The present study is focused on the use of geobag for dredged sediments formed due to immersion of idols formed using Plaster of Paris (PoP). A number of festivals are celebrated in our multi-cultural country wherein idols are worshiped and immersed in water bodies at the end of festival every year. The earlier tradition of clay idols has been replaced with idols being made using PoP and painted and decorated with variety of colours to enhance its beauty. This has led to the problem of water pollution with the paints and colours affecting the marine life and gradually entering into our food chain. The disintegrated PoP particles also result in problem of sedimentation thereby reducing the depth of water bodies and reduction of dissolved oxygen in water. The objective of this study is to determine the performance of Geobag for dewatering of dredged sediments from water bodies.

Keywords: Plaster of Paris; Sedimentation, Hanging Bag Test; Pillow Test; Dewatering Efficiency; Filtration Efficiency, Geobags./

- INTRODUCTION

Rapid industrialization has lead to the enormous quantities of waste. This waste can be either solid or liquid, which is having severe disposal problem. Generally this waste are dumped either in land or water bodies which results in water pollution, directly affects the aquatic life and food chain. This paper is focused on the problem of sedimentation in water bodies, for this geobag can be proposed as possible solution.

India is a religious country, where in every year thousand of idols of lord Ganesha and deity Durga are immersed in water bodies like lakes, reservoir, ponds, rivers and canals. Mostly these idols are made up of Plaster of Paris (PoP), clay and cloth supported by small iron rods, and is colored with different types of paint such a varnish and watercolors. Idols traditionally made of ‘shadu’ (a specific type of soil) are becoming costlier and PoP is fastly replacing ‘shadu’. PoP is not a natural occurring material, it is a calcium sulphate hemi-hydrate: (CaSO4, ½ H2O) derived from gypsum, a calcium sulphate dehydrate (CaSO4, 2 H2O), by firing this mineral at relatively low temperature and then reducing it to powder. PoP solidifies and hardens after forming a paste and also easy to mould therefore widely used for preparation of idols, which creates many environmental problems. When this idols are immersed in water it take several months to dissolve and in the process poison the water of lakes, ponds, rivers and sea because the chemical paints and colors used to decorate this idols contain carbon, mercury, cadmium, varnish, oil paints and lead and this increases the acidity and heavy metal content in water as it seeps with idols.

Ideally these paints should be made from natural colors, and pigments found in vegetables, fruits, minerals etc. Nowadays paints that are used on idols are industrially produced through chemical processes. The basic structure of paint uses pigments, binders, and other such additives. Industrial paints use binders and additives that are synthetic. These additives and binders made from chemicals which impact the ecology of water bodies negatively. When any amount of paint is led off into the water bodies it will cause water pollution, result it will affect the aquatic life and gradually it will enter into food chain.

Another problem will likely to be occurring in huge when immersion of idols takes place as every year has led to an increase in amount of clay, PoP and sand which leads to sedimentation. Sediments are the sinks for elemental cycles in aquatic systems and are recognized as one of the largest sources of inplace pollutants. As PoP idols take several months to dissolve and disintegrate. Result dissolved oxygen of water goes down and suspended solid increases. Water becomes turbid and massive fish mortality due to clogging by gypsum particles, lead level in water was also increased. Sedimentation of gypsum in the water reduces the depth of the water bodies- also gypsum clogs the natural water springs of the water body. These practices make the water bodies not suitable for usage and thus converted into a large septic tank making water body shallower and shallower day by day.

To overcome all above remedies the geobag method is proposed as one of the containment system for pollutant sediments which are present in water bodies.

2. GEOBAG

Geobag are constructed of high strength tubular containers ,made up of permeable geotextiles and are resistant to ultra-violet light and the stresses associated with filling and placement including: abrasion, tearing, puncturing and flattening. This factor ensures long-term dewatering performance. Dewatering is the primary duty expected from a successful geotextile tube. It is designed to contain and dewater dredge spoils, industrial and municipal sludge and other slurry products. When it is filled with high-water content materials by hydraulic pumping, then it is left to dewater. For successful dewatering, first requirement tube should not be clogged during the process and the second requirement is successful retention performance.

In Geobag pore size of the fabric plays a major role. Like when these tube are used in dewatering slurries, a filter cake forms on the interface of the fabric of tube. The formation of the filter cake, which leads to the retention of the soil particles, can be controlled by the pore openings of the geotextile, the particle size, the water content of slurry, and the pumping pressure.

3.SCHEMATIC DIAGRAM

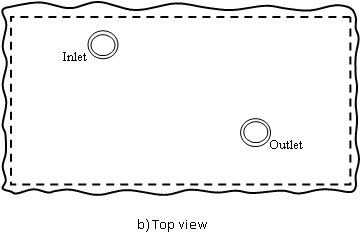

Figure 1 shows the schematic view of geobags. Simplest Geobag is two sheets of geotextile sewn along the edges, with inlets and outlets sewn, depending on the sedimentation and angle of repose of dredged material. Length of the geobag is limited only by the weight of the geotextile material that can be handled in the field. From inlet water content is fed into it and from outlet excess water is removed. This two geotextile sheets can either be sewed or fused as per specification, seam strength is normally the weakest link in the design. While filling the general shape of the geobag change i.e. as the hydraulic filling continues, shape of geobag also increases and as drainage occurs the height of geobag decreases. To support the geobag while the process of dewatering wedge block is provided

4.TEST METHODS

There are two performance tests available for the selection of fabrics for geobag successful applications.

- Hanging bag test

- Pillow test

4.1HANGING BAG TEST

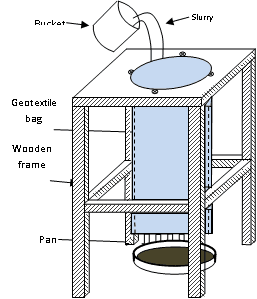

The hanging bag test (Fig. 2) was originated by Jack Fowler of the U.S. Army Corps of Engineers in the mid-1990s (Fowler 1995). It was eventually formalized as a standard in 2004 (GRI-GT14 2004). There have been several papers written about the test that are generally favorable insofar as fabric selection is concerned, e.g., Zofchak (2001), Beuijen et al. (2007), Koerner and Koerner (2006), and Liao and Bhatia (2006).

In this test fabric is sewn into a cylindrical form and further sewn at the bottom. The top of the bag is left open from where high water content material is poured into the top of such a bag, water flowing out of the fabric at the bottom. In the bag after it was cut open, it was found that filter cake builds up on the inside of the fabric which was restricting the foreign particles to get out of it and allowing the free flow of water.

4.2 PILLOW TEST

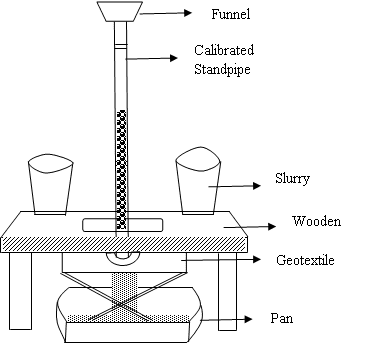

The pillow test (Fig. 3) was originated by Tom Stephens of Ten Cate in around 2005 (Ten Cate Geosynthetics, Inc. 2007) and was formalized as a standard in 2009 (GRI-GT15 2009).

In this test fabric is prefabricated into the shape of a pillow from which a flanged connector and a calibrated vertical pipe is connected. In this test enclosure of a fabric is quite small and the amount of slurry needed for the testing is much less than the hanging bag tests.

As diagram shows water content is poured into pipe with the help of funnel and this content is passed through fabric of pillow shape, after passing it is collected into a pan.