A surgical mask, also known as a procedure mask, medical mask or simply as a face mask, is intended to be worn by health professionals during surgery and during nursing to catch the bacteria shed in liquid droplets and aerosols from the wearer’s mouth and nose. They are designed to protect the wearer from inhaling airborne bacteria or virus particles, but are less effective than respirators, such as N95 or FFP masks, which provide better protection due to their material, shape and tight seal.

Surgical masks vary by quality and levels of protection. Despite their name, not all surgical masks are appropriate to be used during surgeries. Surgical masks may be labeled as surgical, isolation, dental, or medical procedure masks.Chinese health officials distinguish between medical (non-surgical) and surgical masks.

A surgical mask is a loose-fitting, disposable device that creates a physical barrier between the mouth and nose of the wearer and potential contaminants in the immediate environment. If worn properly, a surgical mask is meant to help block large-particle droplets, splashes, sprays, or splatter that may contain viruses and bacteria, keeping it from reaching the wearer’s mouth and nose.[Surgical masks may also help reduce exposure of the wearer’s saliva and respiratory secretions to others that could otherwise travel up to 26 feet. Surgical mask also remind wearers not to touch their mouth or nose, which could otherwise transfer viruses and bacteria after having touched a contaminated surface.

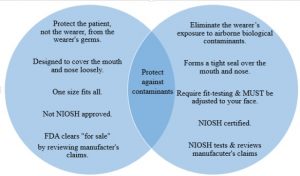

A surgical mask, by design, does not filter or block very small particles in the air that may be transmitted by coughs, sneezes, or certain medical procedures. Surgical masks also do not provide complete protection from germs and other contaminants because of the loose fit between the surface of the face mask and the face.

A surgical mask is not to be confused with a respirator and is not certified as such. Surgical masks are not designed to protect the wearer from inhaling airborne bacteria or virus particles and are less effective than respirators, which are designed for this purpose. Collection efficiency of surgical mask filters can range from less than 10% to nearly 90% for different manufacturers’ masks when measured using the test parameters for NIOSH certification. However, a study found that even for surgical masks with “good” filters, 80–100% of subjects failed an OSHA-accepted qualitative fit test, and a quantitative test showed 12–25% leakage.

Modern surgical masks are made from paper or other non-woven material and should be discarded after each use.

DESIGN OF SURGICAL MASK

The design of the surgical masks depends on the mode; usually, the masks are three-ply (three layers). This three-ply material is made up of a melt-blown polymer, most commonly polypropylene, placed between non-woven fabrics. The melt-blown material acts as the filter that stops microbes from entering or exiting the mask. Pleats are commonly used to allow the user to expand the mask such that it covers the area from the nose to the chin. The masks are secured to the head with ear loops, head ties, or elastic straps.

Figure 1. Differences between face mask and respirator

TABLE 1 Comparisons of Respirators and Medical Masks

| Parameters | N95 Filtering Facepiece Respirator | Medical Mask |

| Intended use | Reduce wearer’s inhalation exposure to certain airborne particles < 100 µm | To protect both the surgical patient and operating personnel from expired respiratory droplets from the wearer |

| Use limitations | Subject to considerations of hygiene, damage, and increased breathing resistance.Use may extend beyond 8 hours only if it is demonstrated that extended use will not degrade filter efficiency and total mass loading of filter is less than 200 mg. | One-time use |

| Filter elements | Nonreplaceable | Nonreplaceable |

| Filter efficiency | 95% | Particle and bacterial filtration efficiency quality indicator |

| Testing aerosol and particle size | Sodium chloride test aerosol with a mass median aero- dynamic diameter particle of about 0.3 µm | Polystyrene latex sphere test aerosol approx 0.1 µm and Staph. aureus filtration test, per ASTM standard (PFE) |

| Airflow rate | 85 L/min | 28 L/min |

| Test aerosol | Charge neutralized test aerosol | Unneutralized test aerosol |

| Preconditioning | Preconditioning at 85% relative humidity and 38°C for 24 hrs | No preconditioning |

| Faceseal fit | Designed to fit tightly to face

Annual fit-test required |

Not designed to fit to face |

| Fit check requirements | Required with each use | Not designed for fit check |

| Source: National Personal Protective Technology Laboratory | ||

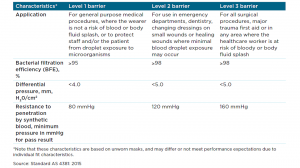

TESTING / REGULATION

TABLE 2 FACE MASK TESTING PARAMETERS

| TESTING PARAMETERS | PROCEDURE |

| Fluid resistance | The ability of the mask to resist the penetration of blood and body fluids.

According to ASTM F 1862, surgical masks are tested on a pass/fail basis at three velocities corresponding to the range of human blood pressure (80, 120, 160 mm Hg). Surgical masks that show passing results at higher velocities are more fluid resistant. |

| Barrier for bacteria | Bacterial Filtration Efficiency (BFE) is a measure of the ability of the mask’s material to prevent the passage of aerosolized bacteria. |

| Flammability | There are many potential ignition sources in the operating room, including surgical lasers, electrosurgical units, endoscopic fiberoptics, and high-energy electro-medical devices. |

| Respiratory barrier for bacteria | A surgical respirator is fitted to the user’s face, forming a seal that provides a physical barrier to fluids, particulate materials, and aerosols. |

| Air exchange (differential pressure) | Differential Pressure (Delta-P) is the measured pressure drop across a surgical face mask material. Delta-P determines the resistance of the surgical face mask to air flowing through the mask.

Pressure drop also relates to the breathability and comfort of the surgical mask. A lower Delta-P translates to increased breathability. |

TABLE 3 FACE MASK STANDARDS

CONCLUSIONS

The major differences between medical masks and respirators are their intended uses and levels of protection .A medical mask is intended to protect others from large droplets exhaled or released by the wearer. It is also designed to protect the wearer’s respiratory tract from splashes of body fluids that may unexpectedly occur in the clinical setting. In contrast, a respirator is designed to protect the wearer from hazardous contaminants in the air. Most N95 filtering face piece respirators are not designed to protect the wearer from splashes of body fluids. However, some N95 filtering face piece respirators (called surgical N95 respirators) have this additional feature as well as regulated by FDA. Medical masks and N95 filtering face piece respirators are considered disposal devices and are not designed for either extended use or reuse after cleaning and disinfection. When selecting a personal protective device for healthcare workers and the public for protection against an airborne infection, an N95 filtering face piece is likely to be both the least expensive and the most widely available However, some of these alternatives may be considered prohibitive in terms of cost, training required, ease of use, and/or availability in sufficient quantities to protect healthcare workers and the public in the event of a pandemic.

Authored by-

J.ANANDHA KUMAR

M.Tech.(Text),M.B.A.(Apparel Mgt),DIM,PGDIM,PGDIB,MISTE MIE (Ph.D.)

LECTURER/TEXTILE PROCESSING

GRG POLYTECHNIC COLLEGE, KOILPALAYAM, S.S.KULAM POST

COIMBATORE, TAMIL NADU STATE

E-MAIL:[email protected], Mobile Number : 09894195264