Introduction

Colouring of cellulose substances with reactive dyes is a very popular commercial approach.

Reactive dyes are known as the best for cotton for its wide range of application and better fastness properties. Reactives are the most important class of colours for the dyeing of cotton.

For the wide range of application and better fastness properties reactive are the superior for cotton fabric.

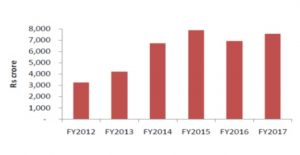

India enjoys leading position in the reactive dyes segment (end use in cotton textile segment) with low threat of imports. Demand of reactive dyes has grown at healthy CAGR of 8% for the period FY2012-FY2017.

The major export destinations of dyes are United States of America (USA), followed by Turkey, Bangladesh, Germany, Italy, Brazil and China. Reactive dyes contributed 52% in total exports volume

CARE Ratings expects domestic dyes industry to witness growth of around 8.50% over FY2017-FY2022 mainly driven by growth in exports volume and demand from textile industry. Key drivers for growth shall be increase in disposable income, higher penetration in the rural market and around 75% share of cotton fabric in total fabric consumption. 1

There are three areas involved – Sustainability, Reactive Dyes and Cellulosic Coloration. Relevant information pertaining to the above three areas are presented in this paper.

Major causes for market share increase of reactive

Substantial increase in cotton consumption in recent years. Strong demand for bright and deep shades. Wide shade spectrum . Excellent brightness. Acceptable wet fastness level. Suitability for all application techniques of Dyeing & Printing methods on any conventional or modern machines by exhaust, semi-continuous & continuous systems. Research and development efforts for meeting the environmental requirements. Easy availability and cost effectiveness.

What is sustainability?

Sustainability is the ability to exist constantly and the capacity to maintain a Process or State indefinitely. It is also expressed as meeting the needs of the present without compromising the ability of Future Generations to meet their own needs. An Unsustainable situation occurs when Nature Capital (the sum total of Nature’s Resources) is used up faster than it can be replenished.

Sustainability requires that Human Activity which uses Natures’ Resources at a rate at which they can be replenished naturally.

In addition to natural resources, we also need social and economic resources. Sustainability is not just environmentalism. We also find concerns for social equity and economic development.

Reactive Dyes Market 1

India enjoys leading position in the reactive dyes segment (end use in cotton textile segment) with low threat of imports. Demand of reactive dyes has grown at healthy CAGR of 8% for the period FY2012-FY2017.

Structural changes in environmental regulations in China have improved cost competency and sales volume of Indian domestic players while reducing imports of dyes intermediates.

CARE Ratings expects domestic dyes industry to witness growth of around 8.50% over FY2017-FY2022 mainly driven by growth in exports volume and demand from textile industry.

Domestic Dyes Industry

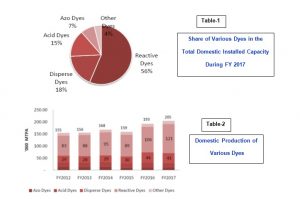

In India the total installed capacity for various dyes is estimated at 380000-400000 MTPA as of FY2017. The domestic production of the dyes is estimated at 205000 MT during FY2017.Both Reactive and Disperse dyes are major contributors for the total installed capacity as well as production.

Source: Department of Chemicals & Petrochemicals

Source: Table – 1&2 Indian Dyes and Dyes Intermediate Industry, Ratings, careratings.com

November 10, 2017

Overall demand driver for domestic dyes in India is textile Industry with 70% consumption of dyes followed by Food (8%), Leather (6%), Paper (5%) and other Industries (11%). India is the major player in the reactive dyes segment with low threat of imports. Hence, demand of reactive dyes has grown at healthy CAGR of 8% for the period FY2012-FY2017.

Export trend of dyes in India

The major export destinations of dyes are United States of America (USA), followed by Turkey, Bangladesh, Germany, Italy, Brazil and China.

Reactive dyes contributed 52% in total exports volume followed by Azo dyes (25%), Disperse dyes (6%), Basic dyes (4%), Acid dyes (2%) and Other dyes (11%) during FY2017.

Source: Department of Chemicals and Petrochemicals

Source: Table –3 Indian Dyes and Dyes Intermediate Industry, Ratings, careratings.com

November 10, 2017

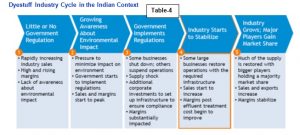

The Indian Dyestuff Industry is well placed for long term sustainable growth

Source: Table-4. Bodal Chemicals – Coming out with flying colours, Investor Presentation, March, 2017

Source: FICCI, Ministry of chemicals & fertilizers, Systematix Institutional Research, Industry Reports, Company Annual Reports, Gujarat Dyestuff Manufacturers’ Association, Bloomberg

Source: Table-5, 6, &7 Kiri Industries Limited, Investor Presentation December 2018, www.kiriindustries.com

Justifications for the growth are

- Strong growth in key end-user industries.

- Tightening of environment norms and increasing operating cost in China.

- Rising demand for finished products from India.

- Shift from generic / commodity to high value specialty / eco-friendly colourants.

- A switch from small and unorganized players to large integrated players

Ideal sustainable product 4

- Provide an equivalent function to the product it replaces

- Performs as well as or better than the existing product

- Be available at a competitive or lower price

- Have a minimum environmental footprint for all the processes involved

- Be manufactured from renewable resources

- Use only ingredients that are safe to both humans and the environment

- No negative impact on food supply or water

Necessity for Sustainable Products4

- 2012 – World population 7 billion 2050 -expected to rise to over 9 billion

- Increases demand for food, energy, water, resources, chemicals

- Increases environmental burden -pollution depletion of finite non-renewable resources (g. fossil fuels)

Three Pillars of Sustainability & Sustainability Criteria 5

Environmental – Ecosystem Services, Green Engineering & Chemistry, Air Quality, Water Quality, Stressors – Reduce effects by stressors, pollutants, greenhouse gas emissions, genetically modified organisms, Resource Integrity–Reduce adverse effects by reducing waste generation, increased recycling, and ensuring proper waste management; restore resources by mitigating and cleaning up accidental or intentional releases

Social – Environmental Justice, Human Health, Participation, Education, Resource Security, Sustainable Communities

Economic – Jobs, Incentives, Supply and Demand, Natural Resource Accounting, Costs, Prices

The United Nations Sustainable Development Goals – The Global Agenda 6

In October 2015, more than 150 countries adopted 17 Sustainable Development Goals (SDGs) to end poverty, protect the planet and ensure prosperity for all by 2030.

Governments, Organizations, Businesses and Civil Society need to play their part For the Goals to be reached. It is generally acknowledged that in order for meaningful progress to be made towards the SDGs, all parts of society must work together to meet the targets.

The United Nations Sustainable Development Goals 6

No Poverty 2.Zero Hunger 3.Good Health and Well-Being 4.Quality Education 5. Gender Equality 6.Clean Water and Sanitation 7.Affordable and Clean Energy 8. Decent Work and Economic Growth 9.Industry, Innovation and Infrastructure10. Reduced Inequalities11.Sustainable Cities and Communities12. Responsible Consumption and Productoin13. Climate Action. 14. Life below Water15. Life on Land 16.Peace, Justice and Strong Institutions 17. Partnerships for the Goals

The United Nations Sustainable Development Goals6

Eco Friendly Textile Coloration

Importance and Need

Textiles Manufacture use intensive chemical applications during the fibre production and wet processing. Textile Dyeing Industry had faced many challenges..

Environmental pollution abatement, Maintenance of Eco balance and Social Accountability are increasing priorities over the other issues in the global market environment.

The impact of Green Chemistry in Coloration is seen in Dye Chemistry, Auxiliary Chemicals & Application Processes.

Solutions for Sustainable Textiles

Systems Needed – ISO 9001, ISO 14001,Good Laboratory Practice( CLP) ,

Good Manufacturing Practice (GMP) Best Available Techniques (BAT ) Cleaner Production ( CP ) &

Green Chemistry.

Eco Needs – German Consumer Goods Ordinance, OekoTex, Organic Cotton, GOTS, Bluesign,

ReaCh, RSL, ZDHC, Detox, Toxic Threads, Cradle to Cradle (C2), ETAD, Cefic, Fluoro Council,

TEGEWA, Sustainable Textile Production, Sustainable Apparel Coalition, United Nations Global

Compact, Global Recycled Standard and others.

Drivers for Sustainable Solutions in Textile Industry

Legislation, Eco labels, Retailers / Brands, Green Consumers, Environmental Management Systems, NGO’s

Source: Table-9. Changing fashion: The clothing and textile industry at the brink of radical transformation, Environmental rating and innovation report 2017 WWF Switzerland, September 2017

Advances-in-Sustainable-Dyeing Cotton Works 8

Sustainable development is development that meets the needs of the present without compromising the ability of future generations to meet their own needs.

Many of the Technologies needed to significantly reduce the environmental footprint in textile manufacturing already exist

- Environmentally Friendlier Preparation for Dyeing & Enzyme Applications

- Environmentally Friendlier Preparation for Dyeing- Cationic Cotton

- Environmentally Friendlier Dyes – High Fixation – Low Impact Reactive Dyes

- Environmentally Friendlier Dyes High Fixation – Low Impact Reactive Dyes AVITERA SE Dyes(Huntsman)

- Environmentally Friendlier Dyes – High Fixation –Low Impact Reactive Dyes Bezaktiv GO

( CHT/Bezema)

- Environmentally Friendlier Dyes – High Fixation –Low Impact Reactive Dyes Cadira Reactive (Dystar)

- Environmentally Friendlier Dyes – Sustainably Produced Dyes – Earth Colors- Archroma

- Environmentally Friendlier Dyes Sustainably Produced Dyes – Levafix ECO – Dystar

- Environmental Impact Measurement – Tools for Measuring Sustainable Dye Methods

- Sustainable Dyeing Equipment – Dyeing: The Road to Sustainability, Efficient Package Dyeing for Yarn, Low Liquor Ratio Jet Dyeing, Low Liquor Beam Preparation and Dyeing, Cold Pad Batch Dyeing, Monforts E-Control, Foam Dyeing and Finishing, Garment Dyeing: Tonello Core, Jeanologia e-Flow, Sustainable Drying Technology, Control & Measurement Systems

SWOT Analysis

Strength

Strong demand for bright and deep shades. Wide shade spectrum . Excellent brightness. Acceptable wet fastness level. Suitability for all application techniques of Dyeing & Printing methods on any conventional or modern machines by exhaust, semi-continuous & continuous systems. Research and development efforts for meeting the environmental requirements. Easy availability and cost effectiveness.

Weakness

High amounts of salt and long dyeing cycles (exhaust) .Low degree of fixation. Need for long washing-off cycles. Moderate light, wet-light, gas fading, photochromy issues and poor chlorine fastness in some shades. Challenges of reproducibility in critical shades

Opportunity

India is now the largest producer of Cotton in the World. Also in the coming years, by enhancing the productivity and performance, it would result in a very favorable situation. Reactive Dyes have great advantage being the major colour for Cellulosic Coloration.

India has a strong base for Reactive dyes manufacture. India also enjoys leading position in the reactive dyes segment meant for Cellulosic Coloration with low threat of imports.

Also in the manufacture and export of various classes of dyes, Reactive Dyes have a leading position.

Threat

Reactive Dyeing have a lesser fixation while comparing with Other Classes Dyes used for Cellulosic Coloration. More control is needed to take care of the Colour in the effluent.

Going Forward – Sustainability of Reactive Dyes for Cellulosic Coloration

- India is now the largest producer of Cotton in the World. Reactive dyes are known as the best Colorant for Cellulosic Colouration. Result is a very value added scenario for Reactive Dyes.

- India enjoys leading position in the reactive dyes segment (end use in cotton textile segment) with low threat of imports. Demand of reactive dyes has grown at healthy CAGR of 8% for the period FY2012-FY2017. It is envisaged that domestic dyes industry to witness growth of around 8.50% over FY2017-FY2022..

- Environmental Solutions as well as Sustainability are key factors for the continuous success of Reactive Dyes as well as Cellulosic Coloration. Lot of Innovative approaches and Development Efforts are in progress from all stake holders for growth and sustainability.

- Reactive dyes are major contributor for the total installed capacity as well as production of Dyes in India.

References:

- Table – 1, 2 &3 Indian Dyes and Dyes Intermediate Industry, Ratings, careratings.com November 10, 2017

- Table – 4. Bodal Chemicals – Coming out with flying colours, Investor Presentation, March, 2017

- Table – 5, 6, &7 Kiri Industries Limited, Investor Presentation December 2018, www.kiriindustries.com

- New Sustainable Chemistry, A Presentation, Textile Centre of Excellence, [email protected] 4th April 2017.

- Sustainability Primer

- Table -8.Sustainable Development Goals, UNDP

- Table – 9. Changing fashion: The clothing and textile industry at the brink of radical transformation, Environmental rating and innovation report 2017 WWF Switzerland, September 2017

- Advances in Sustainable Dyeing Cotton Works, cottonworks.com

NSK SRINIVASAN & HASMUKH SHAH

UMTA Management & Texstyles Academy, Vapi, Gujarat, India