ABSTRACT

A variety of chemicals, auxiliaries and dyes are being used in the textile processing industry during productionactivities like sizing, desizing, scouring, bleaching, dyeing, printing, washing,finishing and other auxiliary processes. The chemical procurement, storage, transportation and consumption become routine work in the textile unit. Some of the dyes and chemicals are having potential hazards to the operatives and the surrounding communities and the environment.The chemical management system(CMS) is a comphrensive tool which gives guideline and requirements to comply during daily chemical handling and usage. The present paper describes, how the CMScan be implemented in the process house.

1.0 INTRODUCTION

The textile sector certainly is not chemically intensive as other global industries, but its variety of chemical operations and materials do present a range of potential hazards to its workers and the surrounding communities and the environment.

In recent years increased attention has been given to the chemicals which are contained in textile products 1, as well as exposure of textile industry workers to hazardous chemicals and environmental effects2. Some of them are by nature hazardous. When the hazardous chemicals are heated, air or with each other, a vigorous reaction leads to accidents. There is a need for more knowledge and also practical tools that can be used to reduce the exposure of operatives and nature to harmful chemicals.

It is necessary for Employers to make necessary arrangements to ensure the safety and health of employees, which handles, store and transports chemicals. In order to make such arrangements the employer has to evaluate work related hazards or potential hazards and develop safety procedures and risk control measures.

2.0 STEPS INVOLVED IN IMPLEMENTATION OF CHEMICAL MANAGEMENT SYSTEM(CMS)

The following steps are involved in the implementation of aCMS in the industry.

- The commitment of Top management for CMS

1.1 Development of CMS team

1.2 Development of CMS Policy and deciding responsibilities of CMS team members.

- Regulation compliance

- Risk assessment

- Chemical Inventory

- Labeling of containers

- Chemical storage and handling

- Emergency preparedness

- Disposal of Hazardous substances

- Training

- THE COMMITMENT OF TOP MANAGEMENT FOR CMS

The top management of industry must commit to comply with regulations and customer requirements, reduce the negative impacts related to chemical use and continuous review of the effectiveness of the whole system should be developed.

In the CMS scope at the initial stage.

- The manufacturer should first list out all the production sites and processes and then define which one needs to be included in the chemical management system.

- After defining the scope manufacturer needs to conduct a chemical risk assessment within the scope.

- Based on the result, the manufacturer can decide whether they need to implement a CMS or simply controls and measures can be implemented. Ex. Prepare or modify existing SOP for chemical use related processes.

A. The first step in chemical management system implementation is to prepare chemical management policy. (Sample Format as given below)

B. Prepare organization charts and appoint a person to manage the chemical system.The organization chart should clearly define the role and the name of the responsible person

3.1. PREPARATION OF CHEMICAL COMPLIANCE POLICY (Sample Format)

Chemical Compliance Policy

We at XXX YYY ZZZ are committed to manage hazardous chemicals (covering physical, health, safety and environmental hazards) during selection, use & discharge of each chemical consumed in our plant. The chemical management will cover all chemicals in process, product & waste.

We ensure protection of workers, communities and consumer health by managing compliance of the hazardous chemicals in our production systems, materials and products to the requirements of Brand RSLs and local legislations.

We understand that maintenance of safe and healthy work environment is essential for productivity, quality, cost and above all employees’ well-being.

We also confirm that the chemicals used and produced during our processes will have a minimum adverse effect on human health and the environment, and the use of all toxic chemicals will be eliminated by committingthe date.

We achieve this by:-

- Developing a chemical compliance team to manage hazards in raw materials, waste and input Chemicals.

- Understanding & implementing application methods of chemicals used for each process, as

- Recommended by the chemical supplier.

- Understanding MSDS & technical data sheet of each chemical, especially for its hazard and impact on health & environment.

- Reduce the consumption of chemicals by adoption of clean technology and “green” products

- Random testing of our outputs (finished article and treated effluent, sludge) and inputs (Grieg raw material, input chemicals, inlet water)

- Health & safety training for chemical hazards for all employees

- Compliance to the RSLs of serviced Brands by:

- Documenting and communicating the restricted substances list (RSL) to our employees and raw material suppliers

- Ensuring correct and complete Declarations from chemical suppliers

- Regularly updating and communicating the revisions in the RSLs.

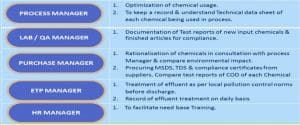

3.2. DEVELOPMENT OF CMS TEAM AND DECIDING THE RESPONSIBILITIES OF CMS TEAM MEMBERS:

Preparation of the CMS team and appointing a person to manage the chemical system.The organization should clearly define the role and the name of the responsible person. The following is an example of CMS team.

THE CHEMICAL PURCHASE PROCESS3:

When purchasing a new chemical following things are required to be considered

- Obtain the safety data sheet (SDS) from the manufacturer.

- Review the SDS from the manufacturer/ supplier before purchasing, and check the hazards, health effects, precautions for use, safe handling information, storage requirements and exposure standards outlined, to determine if further action is required prior to purchase.

This may include:

- Consider if there is a safer alternative if the chemical has been defined as a “Hazardous Chemical”

- Ensure that all safety provisions outlined on the SDS have been considered and appropriate control measures implemented a) Providing Personal Protective Equipment (PPE) b) Ensuring appropriate spill kits/emergency contingency arrangements are in place c) Storage facilities are in accordance with specifications

- Ask for A restricted substance list (RSL) /Manufacturers restricted substances list (MRSL), Confirmation Guarantee Letter.

- Obtain approval from the customs office and other relevant government authorities, if needed

- If approved for purchase, add to chemical inventory and in approved chemicals lists

- Check that labels for all chemical containers (packages) meet the legal requirements

- Keep hazardous chemical purchase and transportation documentation in accordance with regulatory requirements.

- REGULATION COMPLIANCE:

- Management must appoint a specific person to manage regulation compliance.

- He must look for most updated national regulations.

- He must review whole article and list out regulation suitable for the defined scope of the factory.

- List out the regulations

- The Manufacturer can clearly understand whether activities are fulfilling the chemical related regulation or not.

- He must regularly review updated regulations.

- RISK ASSESSMENT:

The risk assessment of hazardous chemicals consists of following steps

5.1 Identify hazardous substances

5.2 Assess the risk

5.3 Control the risk

5.4 Training for employees

STEP 5.1: IDENTIFY HAZARDOUS SUBSTANCES

a. Walk through the workplace, list all substances used or generated

b. Obtain MSDS from the manufacturer/importer (phone number on the label) and check the MSDS to see if the substance is hazardous

c. Check the MSDS issue date is within the last 5 years

d. Create a hazardous substances Register

e. Place MSDS on file, and create an index for the file (index example and template over page)

f. Keep a register readily accessible to workers who use or may be exposed to the substances

g. For non-hazardous substances, including MSDS on the register are optional.

STEP 5.2: ASSESS THE RISKS

Determine who will do the assessment and who will need to have input or be consulted.

- Review MSDS, labels and any other hazard information.

- Inspect work area and talk to staff to determine how the hazardous substances are really being used. In some cases, technical assistance may be needed to establish exposure levels (e.g. – air monitoring, or checking if ventilation systems work properly).

- Compare how the substances are actually being used to the recommendations on the MSDS and determine whether any differences are presenting a risk to safety or health.

- Identify any changes needed and determine how these will be implemented. Ensure the appropriate manager/s is responsible for implementation.

- Document the risk assessment and determine when assessment should be repeated (when things change significantly if problems are reported, or at least every 5 years).

- You can use your own format to keep records.

STEP 5.3: CONTROL THE RISKS

Ensure risks have been controlled as far as practically possible.

- Consider

- Using a safer product (e.g.- a non-hazardous product)

- Using ventilation in the work area or next to the work

- Using equipment to reduce potential contact with chemicals (e.g. Pumping instead of decanting)

- Using the chemical away from other work areas

- Using safe work methods (e.g.- implement procedures and permits for confined space work)

- Selecting personal protective equipment (PPE) suited to the chemical and the work – refer to the MSDS or speak with an OSH professional or safety equipment suppliers. Make sure you choose the correct type of gloves, respirators etc.

- Ensure controls are well maintained and working properly

STEP 5.4: TRAINING TO EMPLOYEES

- Employees who use or may be exposed to hazardous substances need to have adequate information, instruction and training about the substances

- Information and training must cover:

- Potential health risks and toxic effects of the hazardous substance;

- Control measures and how to use them;

- Care and use of personal protective equipment; and

- If applicable, health surveillance required (eg. Blood lead tests)

- Consider language barriers – information may need a translation

- Verbal explanations of the hazards, controls, care and use of PPE and health surveillance (if needed) should be provided

- Keep records of trainings.

NOTE: Simply referring to a file of MSDS and asking an employee to review them is not training.

STEP 5.5: REVIEW

- Ensure MSDS’s are kept updated– each MSDS should be issued less than 5 years ago – call the manufacturer/importer for an updated MSDS copy.

- Risk assessments must be reviewed at least every 5 years – or earlier if problems arise or things change

- New chemicals must be added to the register only after it has been assessed, controlled and staff has been trained

- Controls need to be reviewed regularly to ensure they are working properly – conduct workplace inspections, test ventilation systems, change filters in ventilation systems, inspect and maintain PPE

6.0 CHEMICAL INVENTORY

The chemical inventories should be created and updated to provide clear information about chemicals stored and used in workplaces.The chemical inventory aims at identifying hazardous chemicals in the workplace as well as encourage for proper usage and pollution prevention.

The following steps are involved in the preparation of chemical inventory

- Preparation of Chemical Inventory or chemical log template

- Record of chemical information via Physical Walk-through.

- Record of Chemical Usage (Chemical Balance)

- Regular Review of Chemical Inventory

All hazardous substances purchased for use on-site should be entered in the Chemical inventory. The following information should be included in the chemical inventory or chemical log.

Typical chemical log format contains the following parts.

- General Data

- RSL data

- MSDS data

Overall chemical log format contains following data

- Sr. No.

- Name of chemical Manufacturer/ Supplier

- Commercial name of a chemical

- Category

- Chemical function

- Average consumption per month

- Supplier compliance to RSL – Yes / No.

- Name of RSL

- CAS No.

- MSDS available – Yes / No.

- Signal word

- Hazard identification – Risk phrase or Hazard statements

- Action plan

The chemical inventory or log will be reviewed when new or additional quantities of chemicals are purchased.

7.0 LABELLING

All containers received for use and secondary containers to be clearly labeled as to describe the contents and hazards they contain. Including the following:

- Pictogram: A symbol plus other graphic elements, such as a border, background pattern, or color, thatare intended to convey specific information about the hazards of a chemical.

- Signal words: A single word used to indicate the relative level of severity of the hazard and alert the reader to a potential hazard on the label. The signal words used are “Danger” and “Warning.” “Danger” is used for the more severe hazards, while “Warning” is used for less severe hazards.

- Hazard statement: A statement assigned to a hazard class and category that describes the nature of the hazard(s) of a chemical, including, where appropriate, the degree of hazard.

- Precautionary statement:Statement(s) that convey information on how to prevent or minimize the negative effects of coming in contact with the product. Precautionary statements fall into 4 categories: prevention, response, storage and disposal.

As the employer, the manager is required to ensure that containers in the workplace are labeled. You may use the same label from the supplier or you may label workplace containers with alternatives, such as third party systems (e.g., National Fire Protection Association (NFPA) or Hazardous Materials Identification System (HMIS)) in addition to the other required information.

8.0 STORAGE

The following requirements needto be complied with all hazardous substance storage areas:

- The area is secured and covered.

- Containers are stored on impervious surfaces (i.e. Epoxy treated surfaces).

- Secondary containment units are in place.

- The area is well ventilated.

- Accessible safety shower/eye wash nearby (within 30 meters).

- Restriction on drinking, eating, and smoking.

- Spill kits with materials for containment and absorption.

- Fire‐fighting equipment, fire hoses, and/or fire extinguishers.

- Signs indicating PPE required to work in the area.

- Incompatible materials to be segregated.

- Flammable and combustible materials should be stored away from ignition or heat sources.

- Regular inspections required

9.0 EMERGENCY RESPONSE

The appropriate emergency management provisions should be available for use in the event of a chemical emergency (i.e. Spill or exposure). The emergency response equipment should include:

- Spill kits or containment equipment

- Safe work procedures for spills or release of chemicals

- Fire blankets/extinguishers

- First aid kits

- Eye wash stations/eye wash kits/emergency showers

- Emergency shutdown procedures for equipment

- Appropriate numbers of trained emergency personnel and first aiders

- Appropriately displayed emergency contact details PPE

10.0 DISPOSAL OF HAZARDOUS SUBSTANCES

The chemical wastes should be properly packaged, labeled and stored in suitable designated areas. Labeling will include the material identifier, and a hazard pictogram with the correct classification of the chemical (if relevant). Chemical waste should not be mixed with other waste. PPE must be used when handling chemical waste as per the SDS or risk assessment findings.

Ensure that all hazardous substances are disposed of by qualified contractors who have obtained legal approval to collect, transport, and dispose of each specific hazardous waste category as defined by local law.

11.0 TRAINING

The staff is provided with suitable instruction and training to enable them to work safely with hazardous substances. All staff should receive training on the following:

- Hazards of substances used

- Risks to health presented using those substances

- Relevant workplace exposure limits

- Relevant safety data sheet (SDS) information

- The significant findings of risk assessments

- Precautions to be taken to prevent or reduce exposure

- Proper use of equipment and control measures.

- Proper disposal methods for hazardous substances

- CONCLUSION

The chemical management system(CMS) is a comprehensive tool which gives guideline and requirements to comply during daily chemical handling and usage. While implementing the CMS the commitment from top management is equally important as like the various activities like risk assessment, chemical inventory, chemical storage and handling, labeling, emergency preparedness and disposal of hazardous substances. A proper chemical management policy, training, sustainability focus and top management involvement with commitment are the driving forces for successful implementation of CMS in the process house. We at BTRA Mumbai through technical services would like to assist mills for implementation of CMS in their unit.

References:

- Munn, K., 2011. The Chemicals in Products Project: Case Study of the Textiles Sector. Geneva, Switzerland.

- Stenborg, E., 2013. Making sense of risk. An analysis of framings in media of the chemical risks of textiles, toys and paint. Research Policy Institute, Lund University, Lund, Sweden.

- Chemical management guide and training for manufacturer -1, page 25: powered by Sumerra for Outdoor Industry Association.

Mr. Tanaji Kadam and Mr. Vijay Shirole

Technical services – The Bombay Textile research association, Mumbai

tsd@btraindia.com