TECHNICAL TEXTILES: OVERVIEW

Parinita Devadiga, Manager Marketing, Suvin Advisors Pvt. Ltd.

INTRODUCTION

Technical textiles are ‘advanced materials’ for which the technical performance and physical properties are more important than features such as colour, pattern and price. This industry encompasses a vast array of materials, manufacturing processes and end use markets. Its growth and evolution is driven by the combination of sector lead by R&D and collaboration with other industries.

Technical textiles are used individually or as a component/part of another product. They can be used individually to satisfy specific functions, as a component or part of another product, to enhance the strength, performance or other functional properties of that product. They are also used as accessories in processes to manufacture other products. Other terms used for technical textiles are Industrial textiles, Functional textiles, Performance textiles, Engineering textiles, Hi-tech textiles etc.

Their wide range of applications, lack of competition and growing consumer and industrial demands make it a big opportunity area and an attractive option to invest in. Add to this, the factors conducive for the growth of manufacturing and consumption of technical textiles are also available within the country. Though India is the 2nd largest textile economy in the world after China; its contribution in the global technical textile industry is only 9% to the total consumption.

TECHNICAL TEXTILE: MATERIAL, PROCESS, PRODUCT

Below is the chart showing the raw material and process required to produce different products of technical textiles:

TECHNICAL TEXTILE SECTORS

Depending on the product characteristics, functional requirements and end-use applications, the highly diversified range of technical textile products have been grouped into 12 sectors:-

MARKET OF TECHNICAL TEXTILES

The trend in the various sectors in the textile industry in many industrialized countries indicate that the use of conventional textiles has reached a static level and its manufacture has become highly competitive, often unviable and many companies are switching over to value-added technical textiles with capability to meet functional demands for precision applications.

As use of technical textiles is dictated by need, its pricing normally offers good margins. There is a steady growth of both consumption and production of technical textiles throughout the world. Sector-wise higher growth rates are for Indutech, Buildtech, Medtech, Geotech, Packtech and Agrotech.

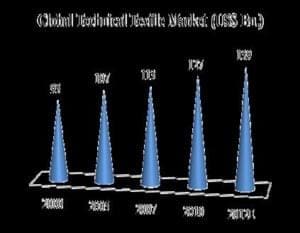

Globally, the consumption of the technical textiles is estimated to be around US$ 139 billion in 2012. At present, USA is the market leader in technical textiles. The Indian Technical Textiles market has grown from Rs. 43,000 crores in 2007-08 to Rs. 63,000 crores in 2010-11 registering a CAGR of ~11%. The technical textiles segment in India has the potential to attract investment and create additional employment opportunities in coming years. Investments of US$ 1.1 billion are expected by 2012 and employment is expected to increase to 1.2 million by 2012. It is forecasted to grow to Rs. 158,000 crores by 2016-17 with a projected growth percentage of 20% growth per annum to be achieved. There are over 3000 units manufacturing technical textiles in India, mostly in small-scale sector. About two-thirds of the production is of commodity products whereas only one-third is high-end.

| Global | India | ||

| Segment | % share | Segment | % share |

| Mobiltech | 24 | Packtech | 35 |

| Indutech | 16 | Clothtech | 17 |

| Sportech | 15 | Hometech | 12 |

| Others | 45 | Others | 36 |

| Total | 100 | Total | 100 |

The consumption of technical textiles is mainly concentrated in developed countries. In many developed countries technical textiles account for over 35% of the textile industry’s output as against 19 % for China and 5 % for India. The technical textile industry in the developed world is maturing and the growth in developed economies is expected to be moderate. In contrast, China, India and other countries in Asia, America and Eastern Europe are expected to experience healthy growth in the near future. The growth in Asia is expected to be 6.5% while it would be merely 2.2% in developed countries. India’s consumption level is different than global level. The top three segments in the world vis-à-vis India are shown in the adjacent table.

India is limited to commodity products with very little presence in high tech segments. There is a general perception that technical textiles are predominantly produced in large scale sectors but it is true only to a limited extent. Technical textiles have been slowly but steadily gaining ground due to one or more of the reasons such as (i) Functional requirement (ii) Logistical convenience iii) Health and safety (iv) Customization (v) Cost effectiveness (vi) User friendliness (vii) Durability and high strength (viii) Eco friendliness (xi) Light weight (x) Versatility

The accelerated growth of the Indian economy has also been impacting favourably on the growth of the technical textiles. With increase in investments in industry sectors, higher consumption and growing exports, the industrial sector is poised for a considerable growth. This will ultimately lead to increased demand of technical textiles products. Industry segment contributes to nearly 28% of the overall GDP and has seen excellent growth in past.

The income of Indian consumer is also growing very fast. This rise will enable them to make more discretionary expense on technical textile products viz. Hometech, Clothtech, Mobiltech, Sportech and Meditech. Per capita income of Indian consumer has increased from Rs. 46,492 in the year 2009-10 to 60,972 in the year 2011-12 at a CAGR of 15%. The fast growing middle class of 160 million with higher discretionary income is expected to increase to 267 million in 5 years. Significantly over 50 % of the population is below 25 years – the vibrant segment for any market.

GOVERNMENT INITIATIVES

Govt has taken initiatives to encourage growth of by providing interest subsidy and capital subsidy on the plant and equipments under TUFS. In order to provide infrastructure support at one place for thrust areas of technical textiles, the govt has already set up eight Centres of Excellence. These centres must be equipped with internationally accredited testing labs, training facilities for technicians from the industry, IT-enabled information centre and other requisite support to the technical textile entrepreneurs.

The eight Centres of Excellence are Bombay Textile Research Association (BTRA) in association with IIT, Mumbai for Geotech; Silk & Art Silk Manufacturing Industry Research Association (SASMIRA) for Agrotech; Northern India Textile Research Association (NITRA) for Protech and Southern India Textile Research Association (SITRA) for Medtech, both in association with IIT, Delhi; DKTE Textile & Engineering Institute for non-wovens, PSG College of Technology for industrial textiles, Ahmedabad Textile Industry’s Research Association for composites and Wool Research Association for Sporttech. Ministry of Textiles has also launched the Technology Mission on Technical Textiles (TMTT).

CONSTRAINTS FOR ENTREPRENEURS In order to promote the production of technical textiles, the first and foremost need would be to attract entrepreneurs in the field of technical textiles. Entrepreneurs have so far kept away from the technical textiles in view of the deterrents such as below:

| · Complex marketing aspects

· Huge capital cost in case of high-end technical products · Requirement of huge working capital · No experience in technical textiles for marketing tie-up

|

· Requirement of huge working capital

· Requirement of specific raw materials, machinery and equipment · Absence of existing norms and mandatory requirements of technical textiles for specific end applications.

|

SUMMARY

India is definitely the next destination hub for technical textiles – manufacturing & consumption which is still untapped. With the growing economy, wide range of applications, lack of competition and growing consumer and industrial demands, technical textiles come out as a big opportunity area and an attractive option to invest in. There is a huge potential in India which is still untapped. A lot needs to be done at the Govt level, industry level and by financial and educational organizations to expedite the growth of this industry.

Some of the steps that are recommended to the Govt to foster the growth of technical textiles are:

- Increase awareness among consumers about technical textile products and their advantages such as better hygiene; cost effectiveness, protective usage etc.

- Introduce technical textile specific courses and specializations in the curriculum of various technical streams like textile, mechanical, and chemical engineering courses. This will result in the increased availability of skilled manpower for technical textiles.

- Frame rules for mandatory usage of technical textiles, such as fire-retardant fabric in cinema halls etc., seat belts and airbags in cars, to create urgency among both manufacturers and consumers to make use of these products.

- Provide subsidies to poor consumers e.g., farmers to buy Agrotech products.

- Establish guidelines and standards for the usage and manufacturing of products where the need to follow standards is necessary for correct usage.

Along with the encouragement from the Govt, the Indian Industrialists also have a large role to play to foster the growth of this industry. Some of the recommendations to the industry are (i) Strive for joint ventures and strategic alliances with international companies for transfer of technology and expertise in this sector (ii) Understand customer needs and cater to the fast growing domestic demand (iii) Invest in R & D, marketing and large scale projects to gain advantages of economies of scale (iv) Thrust upon supply chain effectiveness

Thus it can be summarized that there is a very huge potential in India to become not only a large market but also a manufacturing hub for technical textiles provided there are efforts on part of Govt, industry, academic and research organizations to ensure that the future of the Indian technical textile industry is smooth and fruitful.

References:

- Suvin Book of Knowledge

- Handbook of Technical Textiles, Woodhead Publishing

- Reports – David Rigby Associates

- SASMIRA Texsummit 2007 report