The innovative collaboration between Monforts, Archroma, and Baldwin is driving the textile finishing industry towards the next level of sustainability and beyond.

Building on its groundbreaking partnership with Monforts and Archroma, Baldwin Technology, a brand of BW Converting, will empower textile manufacturers to take the lead in sustainable finishing with its TexCoat™ G4 precision spray system at ITMA Asia 2024, Stand H5A29, October 14-18, at the National Exhibition and Convention Center in Shanghai, China.

Eco-friendly textile production techniques are becoming more and more in demand due to the cost-sensitive nature of the current global economy and the growing focus that businesses, consumers, and regulatory agencies are placing on sustainability.At ITMA Asia, Baldwin’s team will be present to talk about how their technology improves performance and lowers costs while also aligning with the textile supply chain’s goals for sustainability and carbon footprint.

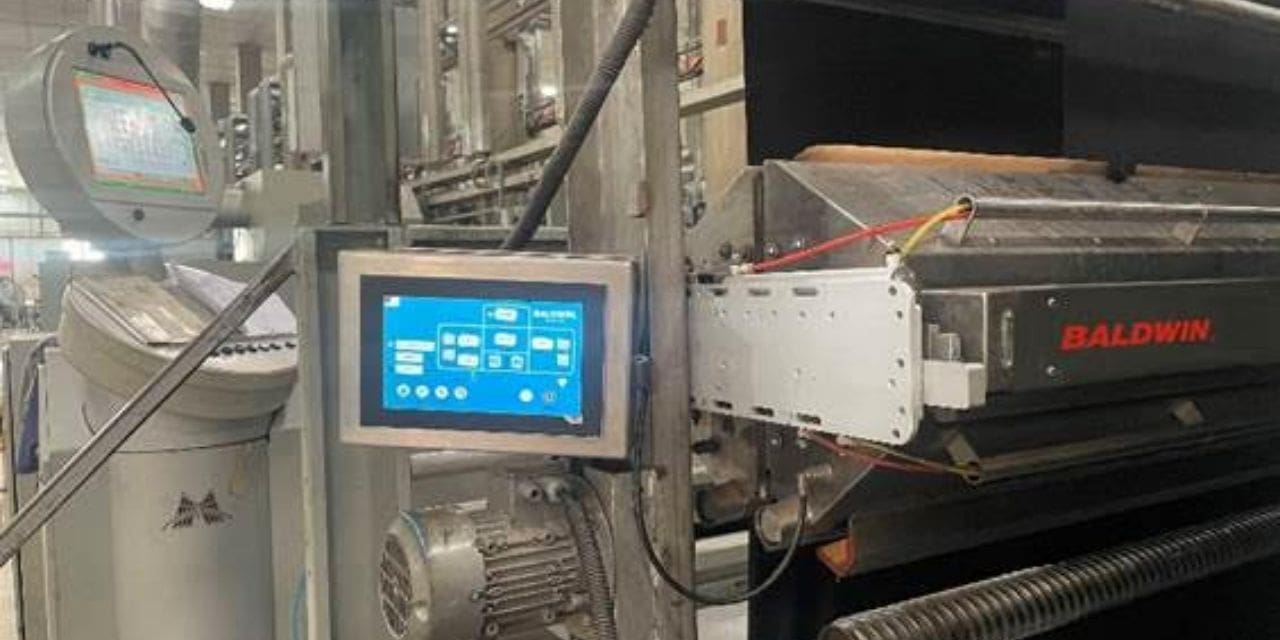

Baldwin’s TexCoat G4 There are several benefits that non-contact spray technology has over conventional finishing techniques. By precisely applying chemicals such as softeners, antimicrobials, durable water repellents, flame retardants, resins, and most other water-based chemicals across the textile surface only where necessary, on one or both sides of the fabric, it transforms the conventional pad-dry-cure finishing process, which uses a lot of water and energy. Therefore, when compared to conventional pad application procedures, the system can save up to 50% on water, chemical, and energy use. It doesn’t require additional additions because it uses the same chemicals as traditional pad baths.

Visitors to ITMA Asia will be able to witness the technology up close and interact with a wide range of fabric samples that were finished using TexCoat G4, which is sourced from textile mills all over the world.

According to Rick Stanford, vice president of global business development for textiles at BW Converting, “Baldwin has enjoyed amazing success in Asia with the adoption of TexCoat G4 with multiple new installations in Bangladesh, China, India, and Pakistan just to name a few.” Because TexCoat G4 is environmentally friendly and quickly pays for itself through reduced use of water, chemicals, and energy, factory owners are investing in it. With TexCoat G4, everyone benefits.

Baldwin’s recently announced collaboration with Monforts and Archroma increases its dedication to environmentally friendly textile finishing. Through this collaboration, next-generation sustainable solutions will be provided by combining Baldwin’s TexCoat G4 spray technology, Archroma’s cutting-edge chemicals, and Monforts’ cutting-edge finishing equipment. The three businesses will work together to support the development projects of dyeing and finishing manufacturers, who are an essential component of the textile supply chain. This will improve the quality and performance of the finished products while optimizing the finishing application process’s productivity and resource utilization.