Düsseldorf, Tokyo and New York – September 19, 2024 –Asahi Kasei, a Japanese technology company, is launching a novel material solution designed to improve the safety of electric vehicle batteries. LASTANTM, a highly flexible and flame-retardant nonwoven fabric, is an excellent substitute for traditional materials in the prevention of thermal runaway. It can be used in the EV battery pack’s top covers, busbar protective sleeves, and other applications.

Even though electric cars are getting more and more popular globally, many automobile owners are still very concerned about battery safety. As per the most recent “Asahi Kasei Automotive Consumer Survey,” 34% of Chinese non-EV owners believe that increased safety is the main factor when purchasing an electric car. In light of this, manufacturers throughout the world are working to increase the safety of EV batteries. The market for materials that stop thermal runaway is predicted to expand by 15% a year starting in 2024 and to continue to grow in the future (IDTechEX: “Fire Protection Materials for Electric Vehicle Batteries 2024–2034”).

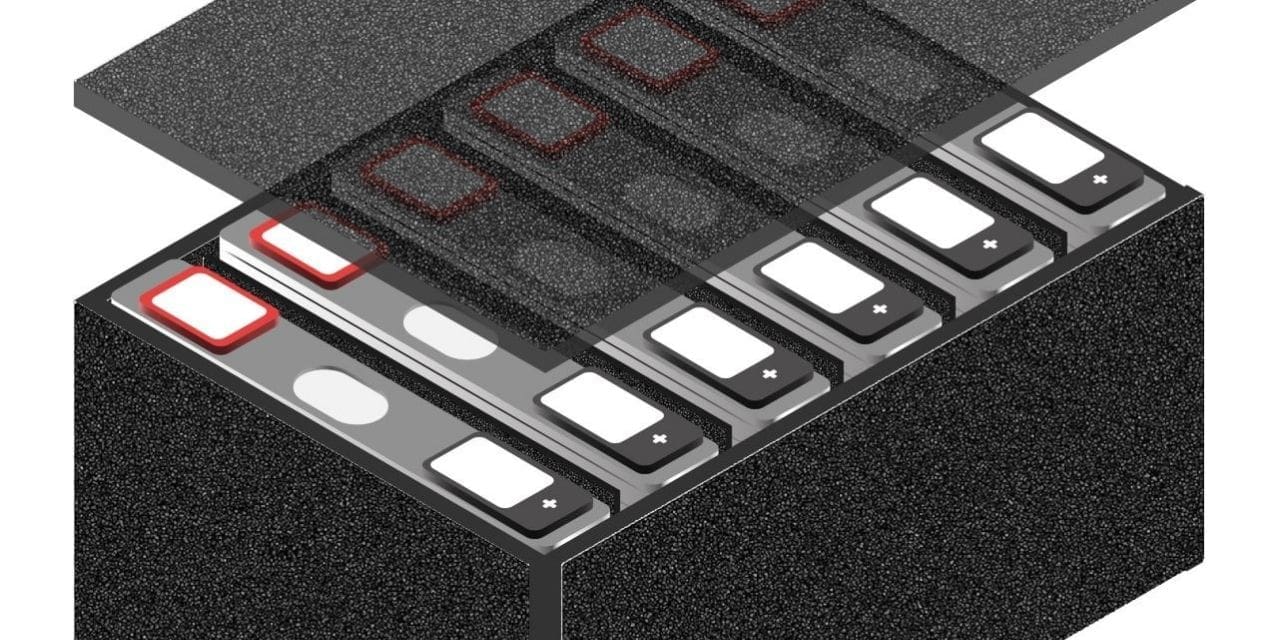

In this regard, there is a growing need for materials with outstanding electrical insulating qualities and exceptional resistance to fires and particle blasts for use in EV battery covers. Currently, thermal runaway protection is mostly provided by mineral-based materials, but these materials are typically brittle and hefty. Because these materials are rigid, it is difficult to mold them into intricate designs, which causes processability issues for automakers.

A unique acrylic fiber is air baked at 200–300°C to create LASTANTM, a non-mineral flame-resistant fabric. Its strong electrical insulation and great flame resistance are enhanced by a unique coating process that further increases abrasion resistance. This makes it possible for the material to effectively shield against gas spewing particle bombardment. Because of these remarkable qualities, LASTANTM has been the best material for safety and failure prevention in a variety of industries for a long time.

Withstanding 1,300°C flames and impact of 200–500 µm particles

On the other side of LASTANTM, the temperature stays below 400°C even when a flame with a temperature of 1,300°C is applied. This material has a “limiting oxygen index” (LOI) value of 50 or higher, even though a value of 27 or above is typically thought to indicate flame retardance. With a 5VA rating, LASTANTM offers the best flame retardance in UL94 tests. LASTANTM does not develop holes, even after one minute of exposure to a flame with a temperature of 1,300°C.

LASTANTM not only has a strong flame resistance but also withstands high pressure impacts from particles with a size range of 200–500 µm. Additionally, it has a 1 mm thickness and an electrical insulating capacity of up to 3.5 kV. Additionally, LASTANTM has exceptional processability and flexibility, even in sheets as thin as 0.8 mm, all while retaining its performance attributes. This facilitates easy processing using common tools, which helps to streamline the manufacturing process.

Asahi Kasei is currently investigating manufacture in the United States and other nations after integrating LASTANTM in Japan. The business will showcase the updated LASTANTM grade in Detroit, Michigan from October 7–10, 2024, at the North American Battery Show.

About Asahi Kasei

The Asahi Kasei Group contributes to life and living for people around the world. Since its founding in 1922 with ammonia and cellulose fiber businesses, Asahi Kasei has consistently grown through the proactive transformation of its business portfolio to meet the evolving needs of every age. With more than 49,000 employees worldwide, the company contributes to a sustainable society by providing solutions to the world’s challenges through its three business sectors of Material, Homes, and Health Care. Its Material sector, comprised of Environmental Solutions, Mobility & Industrial, and Life Innovation, includes a wide array of products from battery separators and biodegradable textiles to engineering plastics and sound solutions. For more information, visit https://www.asahi-kasei.com/.