Dr. P. P. Raichurkar Tushar C. Patil

Associate Dean, Assistant Professor,

Centre for Textile Functions, SVKM’s NMIMS, MPSTME, Shirpur

Abstract

An era is started where innovation is not only limited to the technology development, it is embossing its potential requirement in all the manufacturing as well as networking sectors. Where as in concern with market demand and its fulfillment by using the existing resources is getting the tight rope walk for the management, especially in Textile sector. Apart from the exposure given to technology revolution in textile industry, producing skilled technical cadre of engineers with innovative mindset should also require to be focused. Utilization of available resources including technology and skilled man power is the key for problems which are been tackled during achieving the production and quality targets. Hence, it is getting difficult to balance economic stability of the organization and so entrepreneurs are diverting their mindset from the textile industry to other sectors for investment. Innovation in existing technology which is the only solution to compete, which gives quality and production on par with modern technology available. This paper focuses on the various aspects which will be proven as golden footprints to follow for getting economic as well as technical sustainability in the global textile market.

- Innovation – Review

One of the oldest schism in innovation studies is between technology push and market pull accounts of innovation. In the former case, the initiative behind innovation is supposed to lie in research and invention, with inventors creating opportunities to satisfy people’s needs, often as a result of striving to understand better how things work. In the latter case, the initiative derives from user needs as expressed through market demand and other channels, with these being posed as problems that could do with innovative solutions. The distinction draws a great deal on the supply-push, demand-pull discussion in economics more generally. While most commentators would agree that both between technology push and market pull can be drivers of innovation, there has been considerable controversy around the precise role of each – in general, in relation to the influence on the innovation outcomes (e.g. technology push is supposed to encourage more radical innovation, market pull more incremental ones), and in relation to specific cases and conjunctures. The classic formulation of technology-push is the much-criticized “linear model’’ of innovation. It portrays the innovation process as a set of stages – beginning with research (often in laboratories), moving on to development, and then to production and marketing. One reason for the continuing vitality of this model is the relative ease of funding research as opposed to closer-to-market stages of the process. Another is the visible origin of some very important innovations in laboratory research-based scientific discoveries – the laser is a well-known case. It is apparent that some basic research does result in new knowledge that engenders capabilities to transform the world in dramatically new ways. In contrast, however, are many consultants, case studies and survey analyses, concluding that successful innovation relies upon identification of industry requirements? If design and development are not enough to meet the requirements that have been expressed, then new research may be invoked. But this sound somewhat artificial, because shortcomings with the product may well be experienced by or expressed to the research department directly. Indeed, linear models tend to imply a single flow of knowledge and action, whereas in practice there are many feedback loops and reiteration of activity across stages of the innovation process.

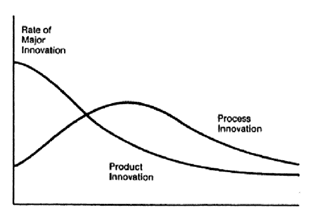

Figure 1. Innovation Matrix

- Product Innovation

Out of this need has arisen a theory holding that the interaction between technology and the marketplace is much more complex and dynamic than the linear view would have us believe. It is our contention here that the conditions required for rapid innovation are extremely different from those required for high levels of output and productivity: Under demands for rapid innovation, organizational structure will be fluid and flexible, whereas under demands for high levels of output and productivity, organizational structure will be standardized and inflexible, Thus, a firm’s innovation attempts will vary according to its competitive environment and its corresponding growth strategy. It will also be affected by the state of development of both its production technology and that of its competitors (Abernathy and Utterback, 1978). Therefore, we can expect to see different creative responses from productive units facing a different competitive and technological challenge, which, in turn, suggests a change in the way of viewing and analyzing possible policy options for encouraging.

2.Process Innovation

The new product technology will often be crude, expensive, and unreliable but will fill a function in a way that is highly desirable in some market niche. Prices and profit margins per unit will be high, because the product often has great value in a user’s application. Several studies have shown that the performance criteria that serve as a primary basis for competition change from ill defined and uncertain to well articulated as a firm travels through the various states of development. Although the total amount of research and development (R&D) in a sector may be large, its focus will be diffuse. The production process reaches the specific state when it becomes highly developed and integrated around specific product designs, and as investment becomes correspondingly large. In this state, selective improvement of process elements becomes increasingly more difficult. Production volume and scale of plants will be large. The process becomes so well integrated that changes become extremely costly, because even a minor change may require changes in related elements of the process and in the product design. Process redesign typically comes in progressive steps, but it may also be spurred either by the development of new technology or by a sudden or cumulative shift in the requirements of the market. If changes are resisted as process technology and the market continue to evolve, and then the stage is set for either economic decay or a revolutionary, as opposed to evolutionary, change. A strong influence will be exerted on suppliers to provide consistent quality and flow of inputs, as these are critical to the unit’s productivity and profits in its now high-volume and low-margin operation. Tasks that cannot be automated may be segregated from the mainstream and performed in separate locations or by subcontractors. Consequently, production scheduling and control, quality control, materials requirements planning and materials handling, job design, labor relations, and capital investment decisions will vary with changes in product and process technology.

Figure 2. Process Innovation & Product Innovation

2.Innovation in Textile Industry – Pathway

Knowledge and capability development is highlighted because demand led innovation requires greater knowledge and competence on the part of suppliers and the users that they engage with. This highlights the role of new design approaches, and ways of managing available resources up to maximum level. In many cases, innovation policy requires collaboration between various service providers, which may also call for regulatory change to promote partnerships between industry, academia and machinery manufactures.

A key idea is that production units may be able to develop the new innovation in the existing technology which may able to produce the quality end product. Spinning, weaving, chemical processing sectors need to promote policy to support the innovation based projects which are to be design in consultation with the machinery manufacturers. Technology is getting smarter day by day, but its leaving the conventional existing technology far behind. Also the new technology is expensive. Thus, it is required to go for process innovation through finding the disadvantages / lacunas of the existing technology and redesign the specific part of concern technology which may be cost effective.

Innovation in the textile industry requires that production units in the spinning, weaving, chemical processing and allied industries be included. Analysis of electronics firms requires review of the changing role of component, circuit, and software producers as they become more crucial to change in the final assembled product. It can be summarized by following points

- Technologies that lift fundamental technical concept on the art without imposing stringent new constraints.

- Designs that enhance the value of potential innovations in other elements of a product or process.

- Technology that ensure expansion into various segments of textile industry.

- Technology that builds on existing operations rather than replacing them.

This could be better explained thorough taking the example of the warp sizing machine, an effective up gradation has been done in the various zone of sizing machine especially in sow box zone, but if we can able to innovate the core technology based 2 Deep 2 Nip concept in the existing sow box then it will give the better results on par with the latest model of warp sizing machine.

2.1 Role of Machinery Manufactures

R & D based Productive innovation will help to machinery manufactures to upgrade the existing technology. Textile machinery manufactures should come forward to support the innovation policy in consultation with production units and academia. Spinning machinery manufacturers like Rieter, LMW and Truetzshcler, Weaving machinery manufactures like Picanol, Toyota, and Karl-Mayer are supporting the projects and training sessions for the industry persons as well as education institutes. This policy should be boosted thorough See & Learn and Work & Learn methodology, which involves the hands on training sessions for students and technical persons from industry on the upcoming technology.

This will leads to build the technical cadre well in advance. Because textile units after setting up or after undergo expansion in various sectors like spinning, weaving and processing adopts the new updated machinery, but unfortunately skilled man power which will able to handle it in the required manner is not available. This leads to increase the loss of efficiency and cost effectiveness of the production units, hence machinery manufactures should come forward to support the innovation policy which further encourages the innovative mindset.

2.2 Innovation through Industry – Institute Linkage Program

Leading textile institutions and the industrial sector can collaborate in the joint projects for the development of emerging technologies of mutual interest. Major thrust areas can be identified by a Technology Up-gradation group involving leading academicians from technical institutions, eminent technologists from reputed industries and talented scientists from textile research associations in the country. Such an effort will surely lead to the development of state-of-the-art technologies pertaining to the industrial sector and promote the collaboration between institutes and industries.

Inadequate industrial exposure to the students affects their ability to effectively deal with the real life industrial problems. This leads to unsatisfactory performance in professional careers. Thus, students must spend at least one full semester in industry to understand the industrial environments and prevailing practices during the project work under the supervision of capable persons. Development of required skills to understand the industrial problems and the tools and methodologies to solve those problems are the resultant gain in this process.

2.3 Work & Learn Pedagogy

In the initial phase of building the skilled technical man power see & learn methodology can be promote the basic technical knowledge, but the task is not completed here. To groom the innovative mind set work & learn pedagogy while working on the production units will be effective. Promoting the textile education while working in the industry will enhance the technical skills of the existing employees. This will help to mould the thinking ability of technical persons towards the innovation track. Process lacunas in concern with the limitation of the respective technology and the proposed remedial measures will be the output of it. Similarly while undergoing the education, textile graduates (Diploma, B.Tech.) should be groomed through work & learn pedagogy by promoting policy for industry funded projects which are based on the technology innovation either through process innovation or product innovation concept.

3. Summary

In summary, to understand how the development and innovation of technology affects productivity and competitiveness, it is essential that we understand the linkages of technologies with manufacturing process, industry sectors, machinery manufactures, and institutions. Maintaining balance and integration among all essential factors leads to set up the innovative mindset in the corporate textile industry. Focusing on manufacturing alone is wholly insufficient. Innovative technology design for manufacture, promoting innovative R&D based policies, and appropriate strategies are also prerequisites for development of innovation in the industry. By the same token, potential for process and product innovation depends increasingly on ability to innovate in technology of manufacturing processes viz. spinning, weaving, chemical processing and knitting sectors.

References –

- Ian Miles, Demand-led innovation, Global Review of Innovation Intelligence and Policy Studies , University of Manchester, March 2010.

- James M UtterBack, Innovation and Industrial Evolution in Manufacturing Industries, 1987.

- Abernathy, W. J. 1976. Production process structure and technological change. Decision Science 7 (October):607-619.

- Abernathy, W. J., and J. M. UtterBack. 1978. Patterns of innovation in technology. Technology Review 80:7(June-July):40-47.