In today’s textile industry, technology plays a crucial role. Efficient data transfer is essential for managing operations, monitoring equipment, and ensuring smooth communication. Choosing the right Ethernet cables for your textile factory can make a big difference in your overall productivity and efficiency. This guide will help you understand what to look for when selecting stable and high-speed Ethernet cables for your textile factory.

Understanding Ethernet Cables

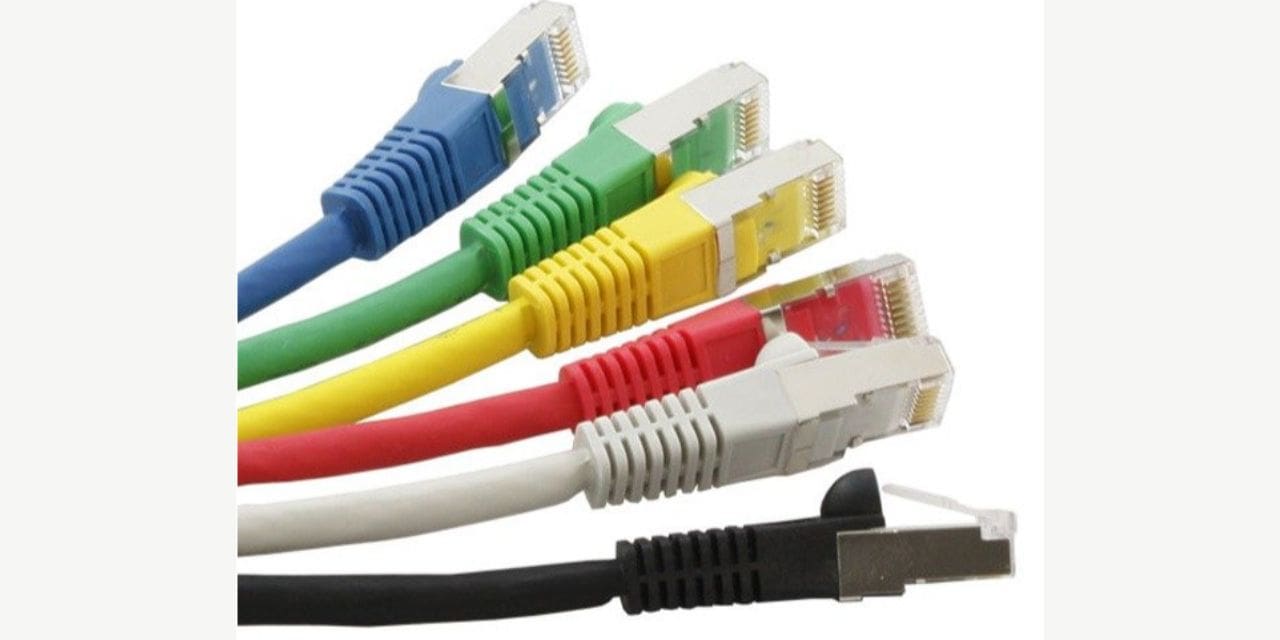

Ethernet cables are a type of network cable used to connect devices in a local area network (LAN). They are essential for transferring data between computers, servers, and other network devices. The quality and type of Ethernet cable you choose can impact the speed and stability of your network.

Types of Ethernets Cables

- Cat5e (Category 5e): This is an improved version of Cat5 and supports speeds up to 1 Gbps (Gigabit per second). It is suitable for most general networking needs and is widely used in many industries.

- Cat6 (Category 6): Cat6 cables support speeds up to 10 Gbps over short distances (up to 55 meters) and have better performance in terms of reducing interference and crosstalk. On the other side, the CAT 6e cable is an augmented specification of CAT6. It is designed to double the frequency from 250 MHz to 600 MHz. There is no standard for CAT6e that is recognized by the TIA like there is for the CAT6 and CAT5e.

- Cat6a (Category 6a): An enhanced version of Cat6, Cat6a supports 10 Gbps speeds over longer distances (up to 100 meters). It is shielded to reduce interference and is ideal for high-speed applications.

- Cat7 (Category 7): Cat7 cables support speeds up to 10 Gbps and have even better shielding to reduce interference. They are suitable for high-performance applications but are more expensive.

- Cat8 (Category 8): The latest in Ethernet technology, Cat8 cables support speeds up to 40 Gbps and are designed for data centers and other environments requiring ultra-high-speed data transfer.

Factors to Consider When Choosing Ethernet Cables

1. Speed Requirements

Determine the speed requirements of your network. For most textile factories, Cat5e or Cat6 cables will suffice. However, if you have high-speed requirements or plan to expand your network in the future, consider Cat6a or higher.

2. Distance

Consider the distance between your devices. Cat5e and Cat6 are suitable for distances up to 100 meters for standard speeds. For higher speeds over long distances, Cat6a or Cat7 are better choices.

3. Interference and Crosstalk

Textile factories can be noisy environments with various electrical machines that may cause interference. Shielded cables (like Cat6a, Cat7, and Cat8) are better at reducing interference and crosstalk, ensuring a stable connection.

4. Future-Proofing

Think about future needs. Investing in higher-category cables now can save you from having to upgrade later. Cat6a and Cat7 are good choices for future-proofing your network.

5. Budget

While higher-category cables offer better performance, they are also more expensive. Balance your need for speed and stability with your budget. Cat5e offers good performance at a lower cost, while Cat6a and Cat7 provide higher speeds and better shielding but at a higher price.

6. Durability and Flexibility

Textile factories require durable and flexible cables that can withstand harsh conditions. Look for cables with strong outer jackets and good flexibility to ensure they last longer and can be routed easily through your factory.

Installation and Maintenance

Proper Installation

Ensure that the cables are properly installed. Avoid bending the cables too much and keep them away from high-interference areas. Proper installation ensures the cables perform optimally and have a longer lifespan.

Regular Maintenance

Regularly inspect the cables for any signs of wear and tear. Replace damaged cables promptly to maintain network stability. Regular maintenance helps in preventing unexpected network failures.

Labeling

Label your cables clearly to identify them easily during troubleshooting or upgrades. This can save a lot of time and effort when managing your network.

Choosing the Right Connectors

Ethernet cables use RJ45 connectors. Ensure that the connectors you choose are compatible with your cables and devices. High-quality connectors ensure a stable connection and reduce the risk of network issues.

Gold-Plated Connectors

Gold-plated connectors offer better conductivity and resistance to corrosion. They are slightly more expensive but provide a more reliable connection over time.

Shielded Connectors

For shielded cables, use shielded connectors to maintain the integrity of the shielding. This helps in reducing interference and ensures a stable connection.

Tips for Optimizing Your Network

Use Switches and Routers

Invest in high-quality switches and routers that support the speeds of your Ethernet cables. This ensures that your network can handle the data transfer rates and remains stable.

Avoid Mixing Cable Categories

While it might be tempting to use different categories of cables for different sections of your network, this can lead to performance issues. Stick to the same category of cables throughout your network for optimal performance.

Manage Cable Lengths

Use appropriate cable lengths to avoid unnecessary slack and tangles. Excessive lengths can lead to signal degradation and reduced performance.

Upgrade Gradually

If budget constraints prevent a complete upgrade, consider upgrading your network in phases. Start with the most critical areas and gradually replace older cables with higher-category ones.

Common Mistakes to Avoid

Using Incompatible Cables and Connectors

Ensure that the cables and connectors you use are compatible. Incompatible components can lead to network instability and reduced performance.

Overlooking Environmental Factors

Consider the environment where the cables will be installed. High temperatures, moisture, and physical wear can affect the performance of Ethernet cables. Choose cables that are rated for your specific environment.

Ignoring Cable Management

Proper cable management is crucial for maintaining a stable network. Avoid tangling cables and use cable ties or organizers to keep them neat and accessible.

Skipping Testing

After installation, test your network to ensure all connections are stable and performing as expected. Regular testing helps in identifying and addressing issues before they affect your operations.

Conclusion

Choosing the right Ethernet cables for your textile factory is essential for ensuring a stable and high-speed network. Consider your speed requirements, distance, interference, future needs, budget, and the environment when selecting cables. Proper installation, maintenance, and cable management can further enhance the performance and longevity of your network.

Investing in quality Ethernet cables and connectors, and following best practices for installation and maintenance, will help you build a robust network that supports the efficient operation of your textile factory. By carefully planning and selecting the appropriate components, you can ensure that your network is reliable, fast, and ready for future growth.