Researchers at the University of Delaware have developed a novel chemical recycling technique that not only preserves cotton and nylon for reuse, but also breaks down polyester and spandex into valuable monomers. By employing this technique, the amount of textile waste that is recycled might be greatly increased, negating the need for labor-intensive sorting and separating procedures.

A significant portion of the 92 million tons of textile waste produced worldwide each year—roughly 100 billion clothing items—is attributed to the fast fashion sector and is disposed of in landfills or burned. Because most clothing has a complex mixture of fibers and additives, separation and sorting become labor-intensive and inefficient, as highlighted by Erha Andini from the University of Delaware. As a result, less than 1% of this trash gets recycled.

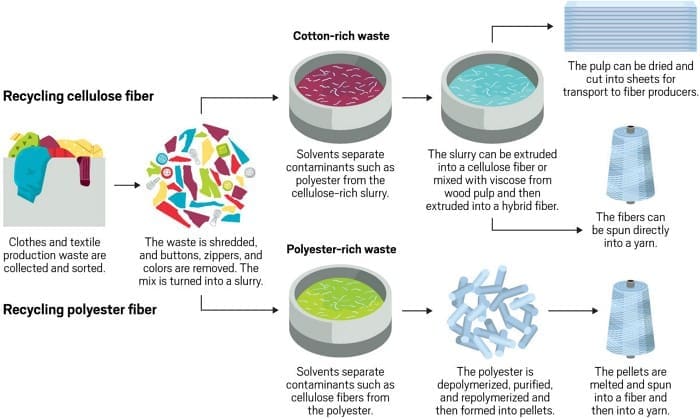

Andini and her colleagues have shown how to extract polyester, cotton, nylon, and spandex from mixed textile waste using a quick and easy chemical recycling process that involves glycolysis supported by a zinc oxide catalyst and microwave energy. According to James Clark of the University of York, this method tackles the intrinsic complexity of contemporary fabrics. Andini recognizes that, despite its assurance.