Customer

Established in 1990, Vaibhav Processing Mills Pvt. Ltd. in Erode, Tamil Nadu holds a prominent position in the textile industry, particularly known for its excellence in dyeing and finishing processes. The company is recognized for its quality retail offerings, including a wide range of colour pigments, and dyed textiles like sarees, towels, and lungis. The leadership of the company consists of Mr Sengodan Palaniappan, Mr Sengoda Mudaliar Babu, and Mr Sengodamudaliar Thangamani, serving as its Director.

Background

For over a year, the Vaibhav’s CBR (continuous bleaching range) was a serious source of concern to management:

- Inadequate production of the right quality

- High maintenance cost

- Frequent breakdowns

The maintenance team at the mill attended to the machine on different occasions to deal with:

- Machine synchronisation problems

- Fabric tension variations

- Malfunctioning of the main operating panel screen

- Electronic breakdown

However, the mill could not resolve the performance issues and put the machine back into operation. At the same time, the OEM’s expensive services and the high inventory cost only compounded the matter.

Solution

It was at this juncture that the customer turned to A.T.E. The mill’s and A.T.E.’s team identified the root cause of the many issues faced by the CBR:

- Lack of synchronisation and tension variation due to poor organisation and an old and non-performing control system of the machine

After a thorough inspection of the CBR, A.T.E.’s team of experts undertook a comprehensive refurbishment of the machine, which included:

- New electronic to pneumatic converters installed for accurate tension measurement on each wash box/nip

- Development and implementation of new software logic for Siemens S7 300 series PLC and SCADA

- Achieved accurate synchronization of the machine at a speed of 50 mpm

- Rectified fabric tension fault completely

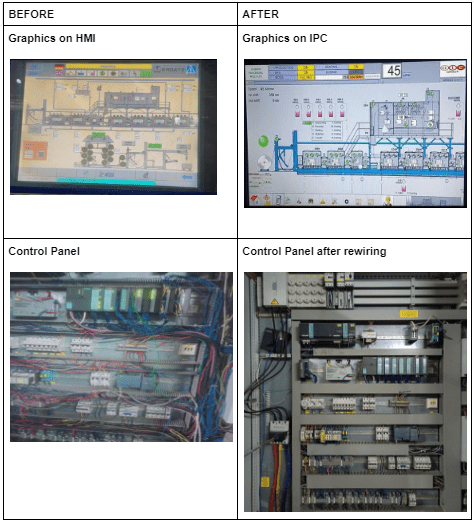

- Replaced outdated operator HMI with a 15” IPC display featuring user-friendly graphics

- Provision of different modes of operation like filling mode and empty mode on the main screen

- Integration of automatic chemical dosing with machine speed and recipe

- Auto temperature and water level controller implemented

- Extensive training provided by A.T.E.’s engineer to Vaibhav’s team for smooth machine operation

Benefits

The effective modification and upgrade of the CBR has substantially improved the machine’s overall performance, particularly in the following ways:

- Machine productivity and utilisation of machines are considerably increased

- Machine operation becomes simple for the operators

- Pressure settings are now done through PLC and hence time is saved and possible human mistakes are eliminated

- Machine life has increased by over 10 years

- Accurate dosing controls yield better quality

- A significantly more budget-friendly alternative than buying a new machine or enhancing the current equipment via OEM.

The outdated OEM Siemens HMI screen was swapped out for an IPC display, complemented by the Siemens SCADA system.