Paithani silk sarees from Maharashtra are renowned for their vibrant colors, intricate patterns, and the precious metal thread used in their creation. These sarees are a must-have in any wedding trousseau, not only due to their traditional significance but also because of their high value, which surpasses that of Kanjeevaram sarees from Tamil Nadu. The Dharmavaram zari saree from Andhra Pradesh, with its pure gold zari, is an exception in terms of both price and design. However, due to their high cost, Paithani sarees are accessible only to the affluent.

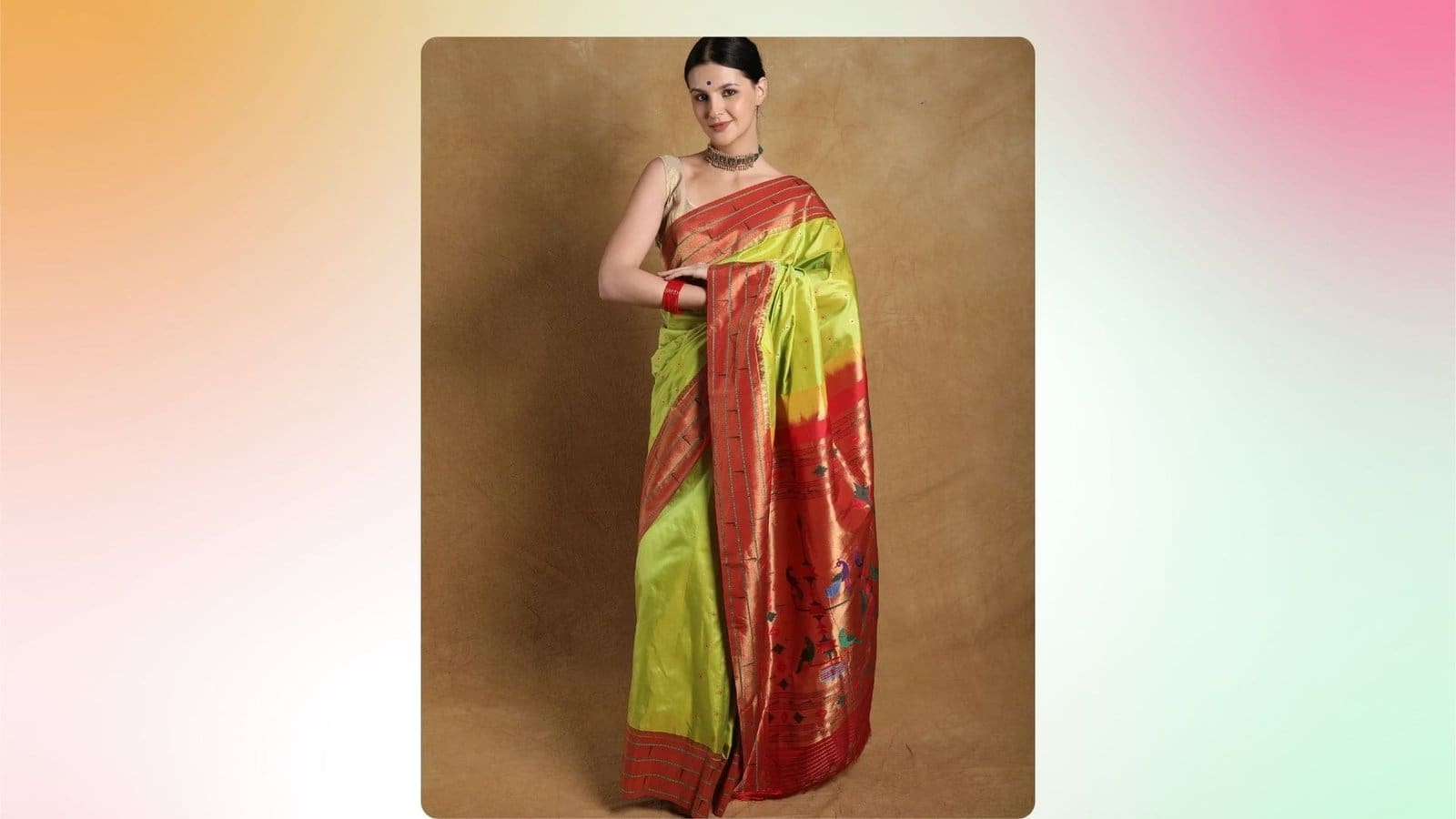

These sarees are made of silk in rich, vivid hues with gold or silver-coated thread work. The weaving process involves a special technique called “dhoop chhav” that creates a unique light and shade effect by combining two different colored silk threads. The traditional colors used in these sarees are obtained from vegetable dyes, with blue, red, and green being the most common.

A Paithani saree with a Norli border takes approximately a month to weave, while a saree with an Asovil border requires almost three months of work. The border design is drawn on tracing paper and printed on the saree, with the weaver manually counting the threads before inserting the silver and gold zari on the design.

The silk used in these sarees is brought from Bangalore, and the zari is sourced from Surat. The coloured zari used for the centers is made of 98% pure silver thread with a thin gold coating. The quality of these materials is assured by the officers involved in the industry.

The cost of a Paithani saree ranges from Rs. 8500 to Rs. 30000, with a profit margin of 10% to 15%. However, prices may vary in the open market, and there can be significant differences from shop to shop and city to city. The demand for these sarees is increasing every year, and the industry is thriving.

There are two major centers for Paithani saree production: Paithan and Yeola village in Nasik district. While Paithan is known for its traditional weaving methods and high-quality sarees, Yeola is famous for its semi-

Paithani sarees, which resemble the original but are made using Jacquard looms. The quality of sarees made in both places is a subject of debate, with some preferring Paithani and others favoring Yeola.

Buyers from cities have no means to determine the origin of a saree, and middlemen often sell these sarees at a profit of 40% to 50%. Despite this, the demand for Paithani sarees remains high, with an annual turnover of almost Rs. 15 crore. The weavers’ main grievance is the reluctance of banks to provide loans and the high-interest rates charged when loans are granted. Nevertheless, the Paithani saree industry continues to thrive.