The report “Basalt Fiber Market by Usage (Composites, Non-Composites), End-Use Industry (Construction & Infrastructure, Automotive & Transportation, Wind Energy, Electrical & Electronics, Marine), and Region – Global Forecast to 2028″, is expected to grow significantly over the next several years, with a predicted valuation of USD 503 million by 2028, up from USD 279 million in 2023. Throughout the predicted period, a strong compound annual growth rate (CAGR) of 12.5% supports this growth. The primary factor behind the growth of the basalt fiber business is the growing demand for eco-friendly materials that possess outstanding strength-to-weight ratios, excellent tensile strengths, and electrical conductivity, among other characteristics. The resurgence of some end-use industries and the expansion of government economic stimulus plans are also contributing significantly to the rise in demand for basalt fibers worldwide.

Browse

• 299 Market data Tables

• 40 Figures

• 232 Pages and in-depth TOC on “Basalt Fiber Market – Global Forecast to 2028”

Some of the prominent key players are:

- Kamenny Vek (Russia)

- Zhejiang GBF Basalt Fiber Co. (China)

- JFE RockFiber Corp. (Japan)

- Mafic SA (Ireland)

- Technobasalt-Invest LLC (Ukraine)

- Russian Basalt (Russia)

- ISOMATEX SA (Belgium)

- INCOTELOGY GmbH (Germany)

- Sudaglass Basalt Fiber Technology (US)

- Shanxi Basalt Fiber Technology Co., Ltd (China)

- Mudanjiang Basalt Fiber Co. (China)

Drivers: Increase in demand for non-corrosive materials

The construction industry’s growing demand for non-corrosive products remains on the rise due to their ability to cut costs and enhance the longevity of structures. Many developments in concrete technology are being made to improve structural integrity and lengthen the life of buildings and bridges. One such invention is the use of composite bars made of corrosion-resistant basalt fiber for concrete reinforcement. Basalt composites, which have a tensile strength three times greater than that of steel bars typically used in building construction, are naturally resistant to corrosion and contain about 80% fibers. These non-corrosive rebars made of basalt roving are strengthened with vinyl ester or epoxy resin, which is incredibly durable. Pultrusion, as well as in-line winding and coating, are steps in the manufacturing process. The rebar is strengthened by the basalt fibers, and the fibers are firmly bound together by the glue. When corrosion is a major concern, BFRP (basalt fiber reinforced plastic) rebars significantly extend the life of civil engineering structures compared to steel rebars. As an appropriate substitute for steel-reinforced rebars, BFRP rebars support structural framework assembly and overall stability.

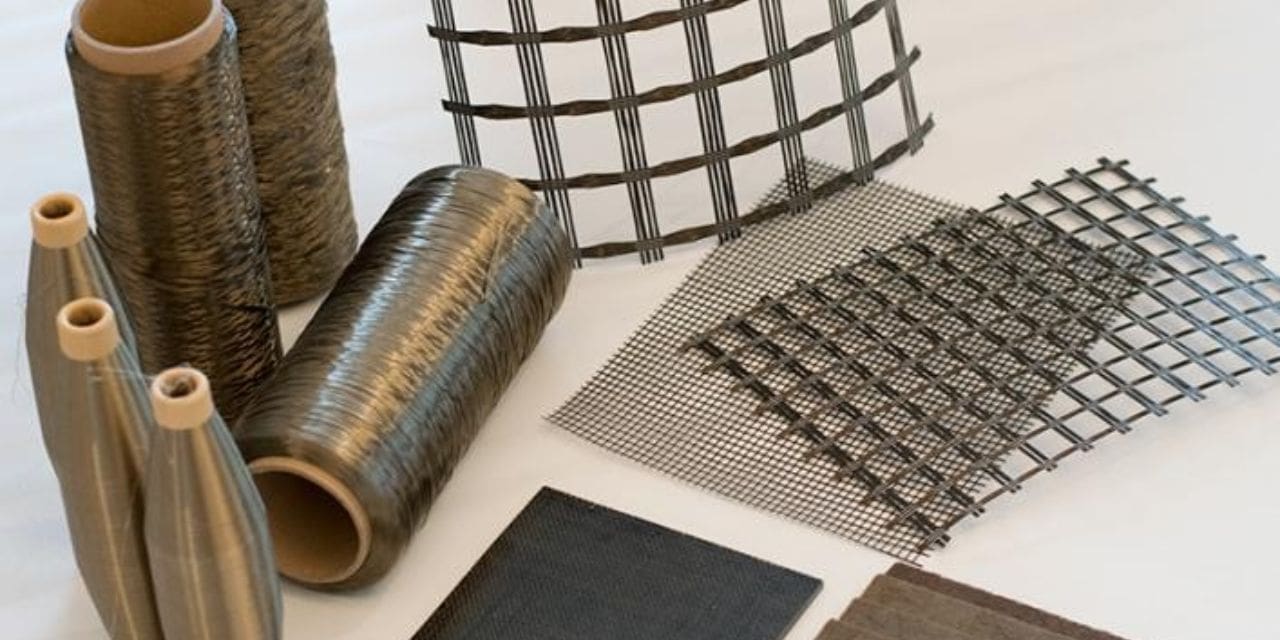

Continuous form to be the fastest growing segment of basalt fiber on the basis of form.

The segment characterized by the continuous form of basalt fiber has emerged as the most rapidly expanding and dominant category within the basalt fiber market’s form type segment. Continuous basalt fiber is recognized for its eco-friendly nature, rendering it suitable for a wide array of applications. These applications encompass the reinforcement of nets, pipes, containers, electrical insulation materials, basalt plastic products, and various others. Furthermore, continuous basalt fibers deliver superior strength, surpassing that of steel, which positions them as a favored material in the construction industry.

Asia Pacific held the largest market share in the basalt fiber market in 2022.

The Asia Pacific region stands out as the primary consumer of basalt fiber, driven by significant demand from countries like China, Japan, Singapore, and others. Anticipated growth in the basalt fiber market in the Asia Pacific (APAC) region is underpinned by the escalating utilization of basalt fiber across diverse industries, including wind energy, construction and infrastructure, electrical and electronics, and automotive. This expansion is also attributed to the burgeoning industrial development observed in nations like China and Japan. Chinese producers of basalt fiber are actively exploring cutting-edge manufacturing techniques that prioritize the creation of continuous basalt fiber that is reasonably priced. Notably, China’s transportation and electrical and electronics industries are big users of basalt fiber, which is anticipated to improve the market’s standing even more. China has a sizable basalt fiber production capability, making it ready to handle unforeseen spikes in demand. Meanwhile, research projects are underway in nations like Singapore and Japan with the goal of creating commercial uses for basalt fiber.