Improved pivot arm is available as an aftermarket modification

GREEN BAY, Wis. – Nov. 25, 2019 – Paper Converting Machine Company (PCMC), part of Barry-Wehmiller, has announced that the redesigned pivot arm on the Omnia embosser-laminator significantly decreases changeover time and reduces the risks inherent to overhead roll removal. The new design will be standard on all Omnias sold, effective immediately. This pivot arm also is available as an aftermarket modification for

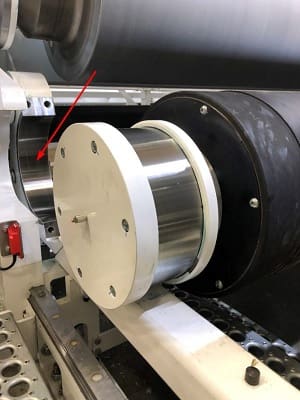

existing machines in the field. Because the shape of the pivot arm has changed, operators can move the lower rubber embossing roll out on rails to an assembly extraction position, from which the embossing roll can be lifted vertically during removal, without the need for rigging and slinging. This improved design reduces the risk of injury or damage during roll removal, and also decreases the amount of time required during a changeover.

“It will save hours in the roll-change process,” said Jason Hilsberg, PCMC Tissue Sales Director. “PCMC is always working to improve the capabilities and features of our machines for our customers, and more specifically, to enhance the experience of the operators. The decreased changeover time this new design offers will bring about a more efficient process to keep tissue operations running quickly and smoothly. It’s a win for our customers, and ultimately, their customers.”