The second most polluting sector in the world is the textile industry. Nearly 20% of the global water pollution associated with textile dyeing operations is attributed to synthetic dyes, which play a key role in this contamination. The use of hazardous chemicals to fix petroleum-based colourants on textiles and non-biodegradable petroleum-based colourants, as well as the subsequent release of these substances into the environment, are the main causes of this problem.

Companies all around the world are taking immediate action by shuttering the majority of the businesses that produce synthetic textile dyes as a result of the implementation of strict legislation. As a result, businesses are actively looking for new ways to finish fabrics in an environmentally friendly manner. Utilising natural dyes derived from degradable plant sources is a possible replacement for manufactured colourants. Toxic fixing agents are nevertheless still required even with this solution. Because of this, both the textile and fashion industries are diligently researching new ways to colour fabrics.

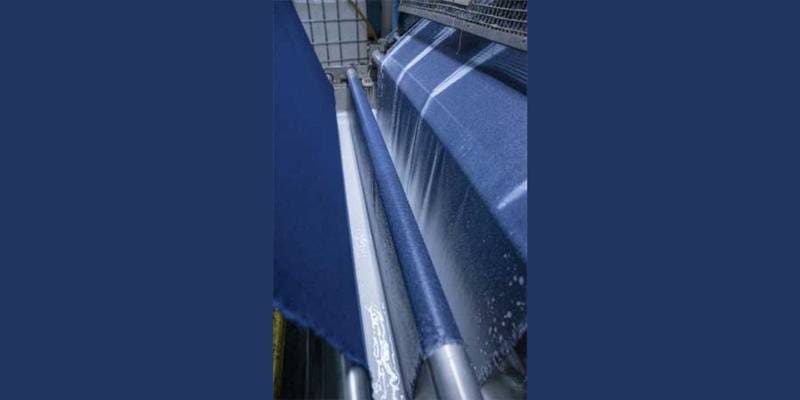

Waterless technologies

The type of fabric affects the colouring procedure. Because cotton fibres have a rough surface, cotton dyeing is a longer, more water- and heat-intensive procedure. As a result, cotton typically only absorbs around 75% of the dye applied, necessitating frequent washing and heating of coloured fabric or yarn and producing a sizable amount of wastewater.

However, some businesses have implemented a system that pre-treats cotton before spinning, accelerating the dyeing process and requiring 90% less water, 75% less energy, and 90% fewer chemicals to produce successful cotton dyeing.

On the other hand, dyeing synthetic fibres, such as polyester, is typically a quicker procedure with high dye fixation rates (the fabric absorbs at least 99% of the colour applied). However, contemporary dyeing techniques might not be as environmentally friendly. Using dispersed colours applied to a paper carrier is an alternate method. Heat alone colours the dye at the molecular level and transfers it from the paper to the surface of the textile. The paper used in this procedure is recyclable, and because the textiles don’t need to be repeatedly soaked and heated to dry, it uses 90% less water and 85% less energy.

Extracting pigments from microbes

The majority of our clothing is now coloured using synthetic dyes, which are produced from expensive raw materials like crude oil and frequently contain hazardous chemicals that are bad for the environment and our health. Natural dyes are a less harmful option, but they still require agricultural land and pesticides to grow the plants that produce the dyes.

In the field of garment colouring, laboratories all across the world have achieved a great discovery: utilising microorganisms. Streptomyces coelicolor, one of these microbes, changes colour naturally based on the pH of its growth medium. Scientists can precisely control the environment it produces to change the colour it produces. Using microorganisms to colour includes a number of stages. The fabric is first autoclaved to remove any potential contaminants. The textile is then placed in a container and a liquid solution containing bacterial nutrition is poured over it. After absorbing the media, the cloth is exposed to the bacteria. For a few days, the complete setup is kept in a climate-controlled room where live bacteria colour the fabric. The fabric is next rinsed and gently cleaned to get rid of any remaining traces of the bacterial medium scent, and then it is allowed to dry. The benefit of employing bacterial colours is that they use less water than traditional dyes do. Additionally, they provide a variety of colours and can be used to successfully dye different designs.

Emerging startups

A number of creative businesses focused on dyeing, processing, and finishing have recently emerged, causing the textile sector to undergo a spectacular revolution. These innovative firms are upending the status quo and revolutionising the way textiles are produced, despite the fact that historically this industry has been hesitant to adopt cutting-edge technologies and sustainable practises. By utilising developments in nanotechnology, biotechnology, and automation, these businesses are addressing industry difficulties that have persisted for a while and laying the foundation for a future that is more efficient and sustainable.

Green dyeing techniques are one area where entrepreneurs have had a substantial impact. Traditional textile dyeing frequently uses hazardous chemicals and uses a lot of water, which has a negative impact on the environment. These startups are utilising non-toxic, biodegradable colours, lessening water waste, and lowering their carbon footprint. In doing so, they are not only lessening the environmental impact of textile production but also satisfying the rising demand from consumers for environmentally friendly goods.