Albstadt, Germany/Milan, Italy: On June 8, 2023, the leading international trade fair for textile machinery “ITMA” started in Milan, Italy. It takes place at the Fiera Milano Rho and runs until June 14, 2023. Groz-Beckert presents the innovations of its six product areas – Knitting, Weaving, Felting, Tufting, Carding and Sewing – in Hall 2, Booth D101.

Knitting

The Knitting product area is showing the novelties of its four product groups Circular Knitting, Flat Knitting, Legwear and Warp Knitting. The Circular Knitting product group is presenting two new knitting systems and a new

compound needle, developed together with cooperation partners, as well as optimized precision needles, system parts and cylinders.

One of the new knitting systems is the innovative LCmax™ circular knitting machine needle in combination with the newly developed sinker SNK-SF. The LCmax™ features a completely new, wave-shaped shank geometry. The use

of the needle reduces energy costs in the knitting process through minimal power consumption and reduced machine temperatures. Compared to a standard needle, up to 20 % of energy consumption can be saved by using the LCmax™. But already the production of the needle is characterized by a reduced CO 2 footprint. At the same time, the LCmax™ enables utilization of the maximum machine speed and easy handling.

The new SNK-SF sinker also features significantly higher wear resistance. It also enables smoother running of the circular knitting machine and improved loop structure.

Together with the innovative sinker SNK DUO-OL, the new SAN™ DUO forms the second new knitting system from Groz-Beckert. Both the SAN TM DUO and the SAN™ DUO feature a particularly low shank with predetermined breaking groove. The low shank minimizes soiling in the knitting process with highly abrasive yarns. The predetermined breaking groove in turn enables controlled needle breakage in the event of wear at the desired point. This reduces errors in the knitting process as well as downtimes.

Another innovation is a new compound needle from Groz-Beckert for circular knitting machines. With this needle variant, the closer is guided safely and precisely in the groove in the needle shank. At the same time, however, the

base of the needle shank is worked in a closed manner, ensuring maximum stability. The compound needle reliably prevents latching and thus makes a decisive contribution to process reliability. Its use ensures a uniform and speed-independent loop structure, even at maximum speeds.

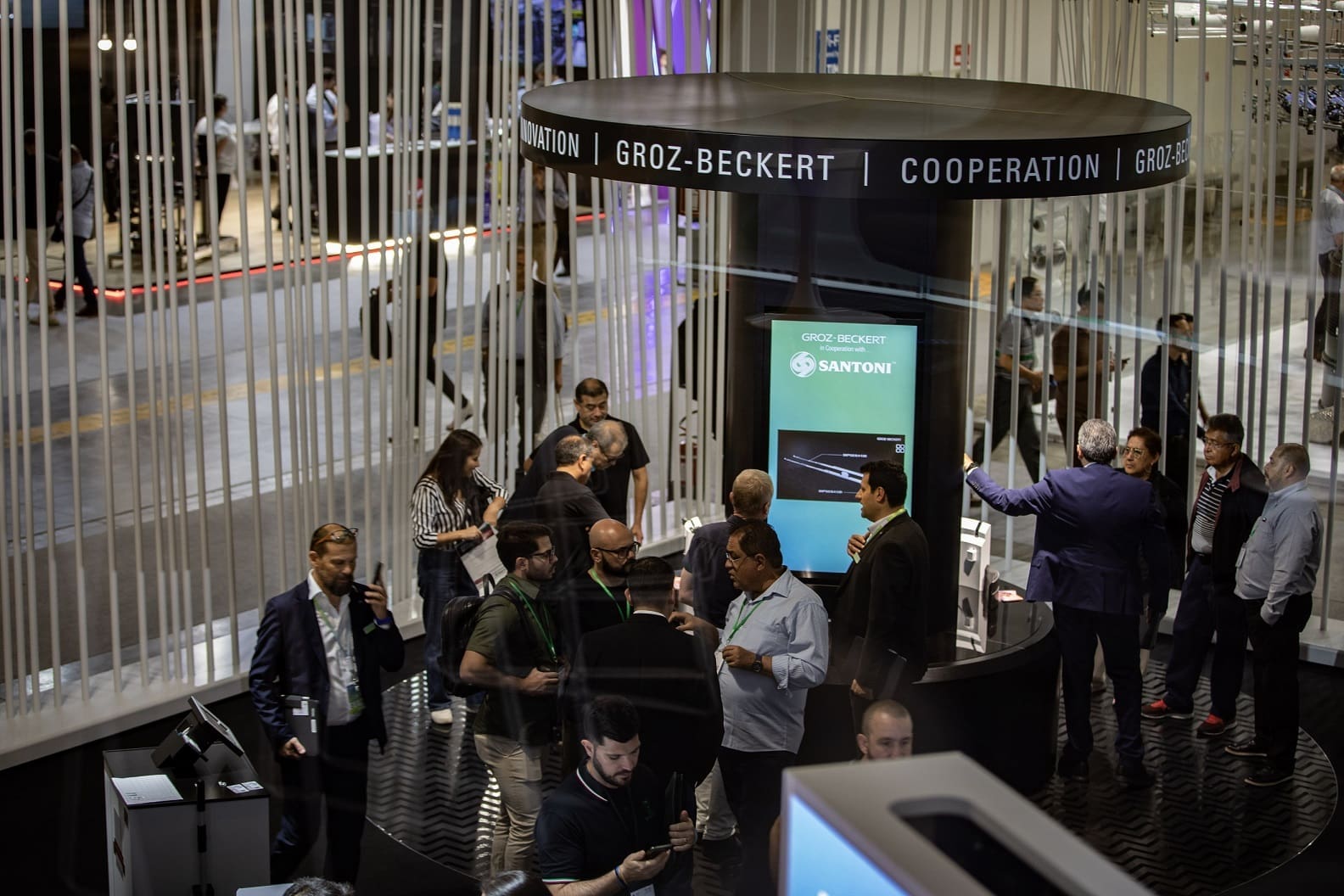

Under the motto “Innovation through cooperation”, live presentations on the innovations of the circular knitting sector will be held at the exhibition booth. They highlight the successful cooperation with development partners.

The Flat Knitting product group puts special application needles at the center of its presentation. The SAN™ TT is particularly suitable for multi-thread knitting of narrow loops in the field of technical or medical textiles. The new SAN FY is designed for processing robust, uneven fancy yarns. The advantages of the SAN TM series are an increase in process reliability and a reduction in needle breakage rates, as well as a particularly precise loop pattern.

For applications where energy efficiency is a key issue, Groz-Beckert offers the flat knitting needle Litespeed plus (LS+). It features partial thickness reduction of the needle shank on both sides. This significantly reduces power consumption and thus the CO 2 footprint in production.

Particularly durable dur™ needles for the sock and fine hosiery sector with high load limits, as well as the steadily growing portfolio of system parts, is presented by the Legwear product group. In addition, products for application-

related use in the production of smooth, plush or patterned plush knits are presented. Thanks to their high resistance, these needles help to reduce knitting process costs.

Its continuously growing portfolio of modules is showcased by the Warp Knitting product group. They enable an individual and varied production spectrum including easy needle handling. The system components have been

supplemented by the newly developed guide needle for piezo jacquard machines. The perforating needles are characterized by fast assembly and ensure an optimized appearance of the fabric. The new punching needle is presented with the specially developed “JacquART Visualizer” which visually and interactively simulates the function and movement of the system parts.

Weaving

The Weaving product area is presenting two weaving preparation machines at its booth: the KnotMaster knotting machine and the automatic drawing-in machine WarpMasterPlus. On the other hand, the division shows its recently

expanded portfolio of technical weaving reeds. The new product makes it possible to supply customers who produce fabrics in the range of high finenesses (both wire and synthetic fabrics). The weaving reeds are used in the production of fabrics used, for example, in technical filtration, membrane technology, solar cells or touch screens.

Felting (Nonwovens)

The Felting product area presents products for classic needling or hydroentanglement. Likewise, its comprehensive range in the field of application advice. In the field of felting needles, visitors can see two world firsts: a new notch design for felting needles and the Groz-Beckert felting needle module.

The new notch design of the felting needles was specially developed for needling highly abrasive fibers to achieve delayed wear. The notch shape also reduces clogging of the notches, for example when needling bentonite mats.

The new Groz-Beckert felting needle module was developed in cooperation with the Dilo Group for their innovative MicroPunch intensive needling technology. Dilo is showing the corresponding machine at its booth. Groz-Beckert felting needles are embedded as a module in a plastic mold. The felting needle modules are characterized by very high deformation resistance and offer new dimensions in needle density. This is made possible by the new

intensive needling technology, which was specially developed for light grammages. The assembly and replacement of the modules are also particularly economical.

In the field of hydroentanglement, Groz-Beckert shows its HyTec TM P jet strip, which features significantly improved wear resistance and handling properties. The division also presents its extensive range of trials on the staple fiber needling line at the Technology and Development Center (TEZ) in Albstadt, Germany, with a virtual tour.

Tufting

For the production of tufted floor coverings such as carpets, bath mats or artificial turf, the Tufting product area is presenting its proven gauge part system at the Groz-Beckert booth. In addition to needle and looper modules,

the system also comprises the reed finger module and tufting knives. To ensure the interaction of all components, the highest precision is required in the production of all individual components. The coordinated combination of

different materials and the functional interaction ensure a convincing result when using the Groz-Beckert gauge part system.

Carding

Various new and further developments are presented in the Carding product area. For those interested in the nonwovens industry, for example, the world’s finest interlinked card clothing for reduced crash risk is included. In addition, new SiroLock™ plus types from the Groz-Beckert InLine card clothing series is presented, enabling higher line availability and a more uniform carding result.

For customers in the spinning industry, the division is exhibiting a new maintenance-free reel clothing with increased service life and lower maintenance costs. In addition, further developed fixed flats and revolving tops

are presented. The revolving tops have been adapted to the processing of fine yarns, while the fixed flats have been provided with a new, resistant aluminum profile.

The comprehensive range of services offered by the Carding division is also presented. All facets, from sales and service to application advice, are clearly demonstrated in a video.

Sewing

The Sewing product area focuses on presenting its special application needles SAN TM . The sewing machine needles of the SAN TM series have been specially developed for demanding sewing operations. The SAN 5.2 TM , for example, is particularly suitable for sewing technical textiles such as airbags thanks to its increased stability and secure loop pick-up. The SAN 6 TM offers high process reliability when processing woven fabrics such as denim.

Both the SAN TM 5.2 and the SAN TM 6 are equipped with a GEBEDUR TM coating. This protects the needles from wear and damage, especially in the point area. The slim yet dimensionally stable SAN TM 10 is used for sewing fine knitted and woven fabrics. The even slimmer SAN TM 10 XS is perfect for extremely fine materials or materials that require critical sewing.

The Sewing product area is also presenting its patented INH (Ideal Needle Handling) quality management system at the trade show. INH enables easy handling of sewing machine needles in sewing shops, as well as seamless and digital documentation of all needle changes and breakages. The quality management system includes various work tools such as the needle dispensing trolley, the needle return box, and two software components developed by Groz-Beckert: the “INH@site” app and the “INH@office” administration program.

Technology and Development Center (TEZ)

The Technology and Development Center (TEZ) is presenting itself at ITMA with a virtual 360-degree tour. Visitors can discover not only the premises but also the extensive range of services. In addition to competent expert advice

and the joint development of solutions for specific textile problems, the TEZ also offers its customers the joint development of new, innovative products, technologies and business models. In addition, training courses and seminars from the Groz-Beckert Academy are offered at the TEZ.

Sustainability

Numerous products, services and the latest innovations from Groz-Beckert focus on reducing the company's carbon footprint. That Groz-Beckert’s commitment also goes beyond this is shown by the sustainability theme

corner. Here, examples from the company are presented to show which measures have already been implemented and what role the topic plays in everyday life.

About Groz-Beckert

Groz-Beckert is the world’s leading supplier of industrial machine needles, precision parts and fine tools, as well as systems and services for the production and joining of textile fabrics. Its products and services support the fields of knitting, weaving, felting, tufting, carding and sewing.

Groz-Beckert is part of the Groz-Beckert Group, a market leader in the development, manufacture and distribution of process-critical textile precision tools, industrial cutting solutions and solution provider for textile construction and reinforcement solutions made from high-performance technical fibers for composite materials.

The group consists of the companies Groz-Beckert, TKM and solidian and generated sales of 814 million euros in 2022 with around 9,500 employees worldwide. The company is active in more than 150 countries with agencies, production and sales subsidiaries.