Retech godet rolls’ innovative designs enable more control over temperature, fibre treatment, and sustainability, revolutionising the production of synthetic fibres.

The blue thread continues to go! At the next ITMA, Retech will exhibit a number of intriguing advancements for heated godets at Stand B108 in Hall 1 under the blue thread theme.

Retech, a fibre drawing expert, will exhibit advances in the following industries in Milan.

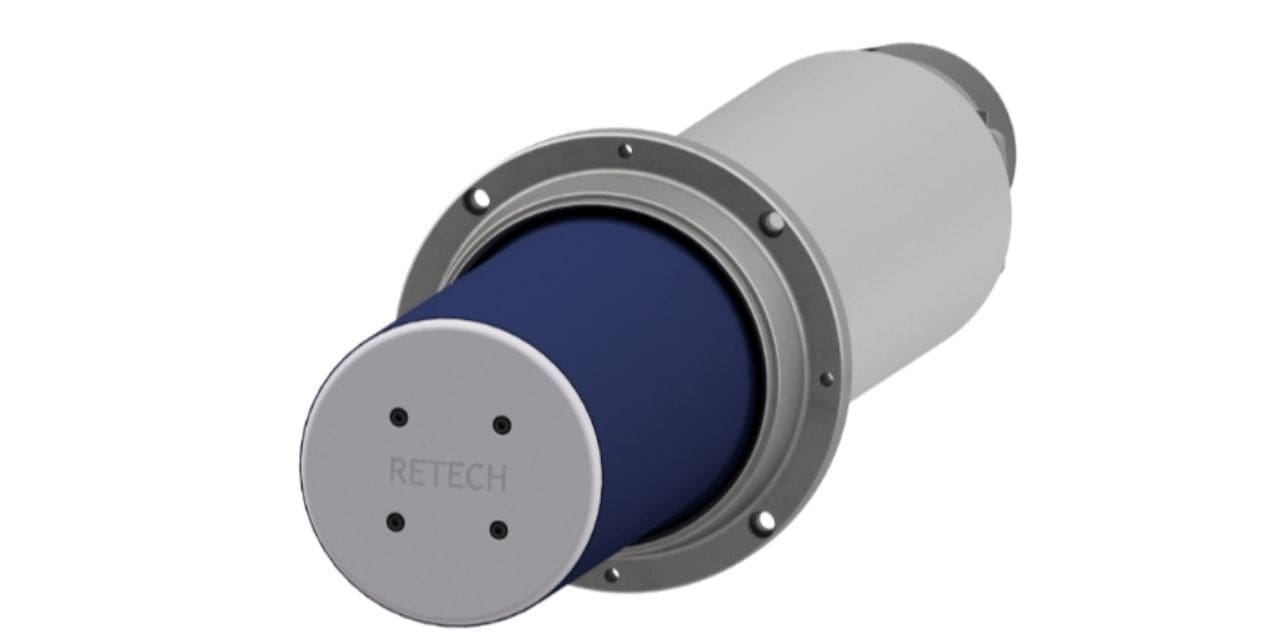

Modern heated godet with IoT

For (ultra) slow speeds, a new drive system

Making blue thread and drawing frames using specialised machinery

Godet rolls are crucial tools in the manufacture of synthetic fibres. The ideal yarn quality is achieved using these heated, ambient, or cooled rolls for When it comes to heat treating for filament fibre applications, there are many different materials and uses. Retech godet rolls’ innovative designs enable more control over temperature, fibre treatment, and sustainability, revolutionising the production of synthetic fibres. Retech has an emphasis on energy economy when it comes to motors and heating equipment in addition to its unique designs. As a result, all Retech devices consume less energy than conventional systems, which over time reduces their overall cost while still producing exceptional results.

The two difficult requirements for Retech’s heated godet rolls were to apply precisely the right temperature for the material being produced and to maintain this level consistently throughout the process. To accomplish this, they add energy-saving technologies into their designs, utilising single-zone or multi-zone heating via resistance, induction, or infrared. This guarantees accuracy and precision in terms of surface temperature profiles and consistently high yarn quality. Due to its lifetime bearings, which require no additional lubrication and low maintenance requirements that result in less downtime, Retech also provides unparalleled value in terms of cost savings. In addition, it has an IoT-ready monitoring capability that guards against any harm brought on by high temperatures or other problems. This enables producers to produce at cheaper prices and with larger yields without endangering the quality or safety of their goods.

How to create sustainable heated godets with IoTs in a contemporary heated godet?

The long service life of the heaters, in addition to the energy-saving motors and energy-optimized heaters already described, is a crucial component of the Retech godet idea. extending product life and the accompanying perpetual availability, lowering machine downtimes and reject production. A godet failure causes a significant loss, annoyance, and disruption to the production process right away. Retech has therefore included extra measurement components to its godets so that it can respond proactively to potential damage and subsequent failure.

What choices does Retech have for its clients, and what are the benefits?

It is possible to take additional measurements, gather data, and evaluate them because of the sophisticated, cutting-edge, and well-proven UTR-6A temperature measuring transmission system, which measures the temperatures in the rotating godet and transmits the data to the temperature controller UCR-6 for processing without contact. To ensure the survival of the godet, continuing production, and ultimately both the godet itself and the entire process.

monitoring of induction temperatures

The temperature of the induction coil can be gauged and tracked using thermocouples, which are mounted in each heating zone of the induction heater. The coil may be harmed and have a shorter service life if the temperature goes above a value determined by experience. If this temperature is surpassed, the system responds by issuing a warning and turning on a cooling function at the same time. Now that the temperature has grown, the operator has the chance to identify and fix its cause.

Monitoring bearing temperature

The bearing life rapidly declines if the temperature rises above a specific point. As the high-temperature grease breaks down, it inexorably causes damage to the bearings and godets. This results in significant costs and downtimes. and losses in manufacturing. As a precaution during planned maintenance work, it is crucial to monitor the bearing temperature and to identify and postpone an approaching bearing deterioration at an early stage until the bearings can be replaced. Retech provides comprehensive bearing failure prevention and monitoring, which is a significant value addition for the operators, due to the ability to install, transmit, display, and evaluate additional temperature sensors in the temperature measurement transmission system below the bearing points.

Vibration detection

Vibrations, in addition to excessive temperatures, can harm a bearing and cause bearing failures. Operators would greatly benefit if excessive vibrations could be identified and indicated. This would enable an early and prompt response, and the root It was possible to determine and get rid of the vibrations. The temperature measurement transmission system has also adopted this measurement. Vibrations at the stator are measured, assessed using the temperature controller, and notified to the operator right away if they are excessive.

The godets made by Retech have a distinctive design that enables users to operate the draw roll at very low speeds of just a few metres per minute or even per hour. No matter how slowly the process must run, this helps to assure optimal performance.

Retech highlights the creation of the blue thread. Watch this happen live. The aforementioned information and goods can be seen in real time using a demonstration item. Vibration readings and bearing temperature are all IoTs. There will be a display and an induction temperature measurement. also the new drive system for godets that run slowly. And to top it off, the blue thread’s inventive design. Retech will demonstrate a modular drawing system to demonstrate its capabilities as a special solution provider for R&D centres, academic institutions, and specialty manufacturers.