A pair of jeans requires roughly 1,800 gallons of water to make, and about 85% of the water used in textile manufacturing is used to dye clothes, which in turn pollutes water sources.

The historic handloom sector in the state has discovered a route to rebirth as global awareness of eco-friendly and sustainable fashion rises. Value addition, according to fashion experts, could turn it into a centre for sustainable fashion.

Lalita Choudhary, a fashion designer based in Rohtak, was brought to the state as a result of one such project. Choudhary was given the task by the SC/ST administration of providing skilltraining for 40 chosen ladies from the scheduled caste group who were attending the Malabar Crafts Mela in Kannur. Beginning in the Travancore Textiles Handloom Weaver’s Industrial (Workshop) Cooperative Society, the project targeted at educating women in surface printing with natural dye and handloom weaving in Thiruvananthapuram. To replace the outdated and inoperable machines in the community, Choudhary imported a new warping machine, loom, and other machines from Haryana.

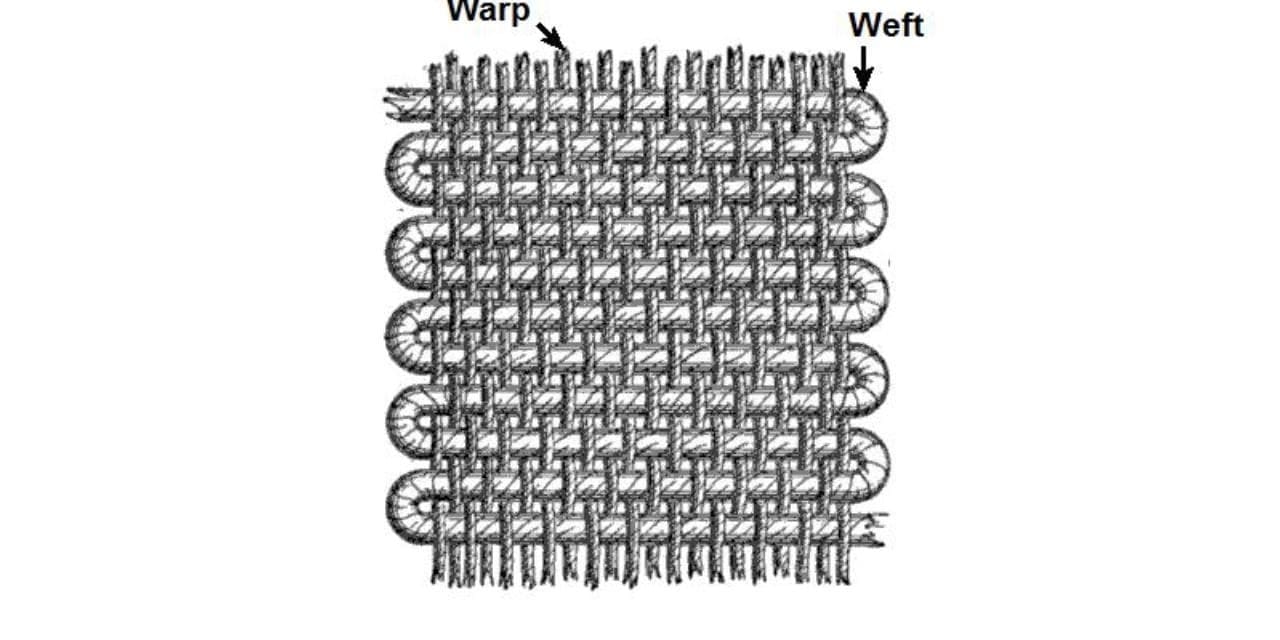

There are skilled weavers here, but sadly they waste their abilities and labour on machinery that is 150 years old. For instance, whereas the conventional warping method takes about seven hours, the warping equipment I brought can warp a 150-meter fabric in about two hours. In addition, these women are obliged to endure hours of uncomfortable standing. Another risky step is shifting the warp to the loom. The workers can get hurt from its lengthy needles, according to Choudhary.

Modernization of the handloom sector, according to textile designer Sumesh B S, echoes Choudhary’s opinions. is essential to its resurgence. “Four to five individuals must now work as a group to transfer the fabric from the warp to the loom. It is a labor-intensive technique that wastes workers, he claimed.

Choudhary praised the government’s initiatives to revitalise the sector, saying: “It is encouraging to notice that the government has been helping the industry by giving orders for various goods including school uniforms and hospital bedsheets. The handloomed garments must be transferred to Tamil Nadu for dyeing and then returned for further work, she added, due to a paucity of dyeing resources.