Interview with Mr. Dilip Barooah , Managing Director and Founder of Fabric Plus Pvt. Ltd.

Mr. Dilip Barooah – a Textile Technologist turned technocrat engaged in rigorous indulgence for 25 years in textile industries across the globe.

- Brand name: Fabric Plus

- Company name: Fabric Plus Pvt. Ltd

- Brand Tagline: 3D fabric that look good, feel good & do good

- USP : Authenticity, innovation, transparency

Inspiration to start business

Fabric Plus has been a medium for our team to explore the various aspects of doing business in textiles in a region as unique as the North East of India that is rich with indigenous resources that are yet to be fully explored. With age-old traditions in spinning, weaving along with sustainability and nature consciousness, the NER has provided us with a rich point of reference for our business modelling. We have been able to understand the process of Eri Silk cultivation and its processing in great detail. Constant R & D and innovation with collaborators across the world allow us to diversify our offerings in the market. Furthermore, the potential of socio-economic transformation is immense. Giving back something to the society with the strength of years of experience and exposure by means of creating livelihoods, with indigenous, abundant raw material of eri / muga silk has also been part of the general vision.

Vision of Company

We established Fabric Plus in the year 2003 in Mumbai, with the mission of strengthening the handloom craft sector through intermediate technology in silk spinning to create jobs. Vision: weaving silk, science, society and tradition into sustainability.

Challenges in the journey

Challenges are welcomed in all fields of our business. We owe it to them for teaching us the difficult lessons too soon, too fast in certain cases. But underlying this fact, we believe that as long as our goal is carved in stone, challenges are nothing but welcomed lessons. Still if we are to state the biggest challenge was to run an industry employing rural hands for more than10 years at an absolutely backward zone without any exposure to industrial work culture.

Opportunities

Along with the first mover advantage, our team was able to coordinate well and leverage with personal networks. Good will and a positive brand perception has also helped a great deal.

Innovation strategies

Constant changes in market trends and consumer tastes push us towards developing upon our product categories, improving them along with diversifying. For this, we have dedicated more than 5% share for innovation. Innovation is the DNA of our company. As individuals, we understand the significance of this and encourage our team mates to constantly thrive to break through the perceived glass ceilings. Our Innovation reflects not only in our Product, our method is equally first of its kind in the country. There is still no handbook available for manufacturing our product. Through years of trial and error we continue to tune and refine our methods.

Creativity with updated technology

Keeping in mind that creativity is not jeopardized by technology. We don’t want our products to be sold as a commoditized product, governed by technology alone but, one that has conscious value proposition including society and science.

GST Effect

Impact of GST happened to be severe as we are still in the middle of the un-organized/semi-organized sector. However, we are waiting for the transition period to get over. Point to be noted that textiles that we deal in were never had even any kind of sales tax, hence introduction of GST played havoc on a two tier assault to these business.

Challenges

Optimization of resources, unorganized raw material market, hoarding by the traders, lesser known product mix, lack of awareness, uncertainty of raw material supply, lesser inclination of the new talents towards silk and textile sector, inadequate amount of R&D by the concerned Govt. agencies etc..

Human Resource for Textiles

Sensitize young talents / new minds to join the sector; rest will fall in order. Ministry should introduce schemes to attract more young talents (skilled in management / technology from premier Institutes) across the value chain. It is rare to find professionally qualified new talents in Textile sector.

Future trends

Fast fashion is going to fade over a period of time. Sustainable Textile is the future textiles for the conscious world. Adequate market positioning, blending with other natural / sustainable textiles will replace and revamp the segment in both domestic as well as global market.

There will be more demand in pure as well as blended fabrics form in the future subject to product innovation, diversification, backward integration. Supporting local entrepreneurs and artisans is our main motto. Collaborating with international agencies such as World Bank, UN, etc. Providing technical assistance to those in need

Branding Strategies

Our branding exercises focus primarily on developing personality/identity, appropriating communications and language, creating awareness in sustainable textiles solutions and acceptability of the same and enhancing increase trust/confidence in our market. We try to maintain a positive feedback loop in order to learn from the data we gather and create.

Importance of

Digital Marketing

Changes in culture and technology call for human behavior to adapt to the

dynamic ecosystem of online engagement. Digital platforms allow us to

understand our demographics better, and become more efficient in targeting

them. It is as important as it is for the consumer market.

Indian

government focus on North East

North east is meant to be a gateway to South East Asia, but we are yet to see

progress towards this vision. The focus of the government on NE although

delayed is ever more crucial. We are at the crossroads of a cultural evolution

and in order to incorporate this region into mainland India, much work is

required.

North East Textile Policy’s Objective isto provide Raw material, Seed bank facility, Skill development, Design and Marketing support. Strategies are to develop Clusters of Handloom and Yarn factory, Marketing of new product lines , Exposures visits, Up gradation of Technology introducing modern looms.

Geographical Indication ( GI)

GI tags help in promotion of regional cultural heritage. The NE is full of such symbols and can help boost the perception of India, as a whole.

Company Profile of Fabric Plus

About us:

Fabric Plus began its journey in 2003 as a prime exporter of “Assam Silk”, based out of Mumbai. It was founded by the present M.D. Mr. Dilip Barooah – a Textile Technologist turned technocrat engaged in rigorous indulgence for 25 years in textile industries across the globe.

We pioneer in the manufacturing of world-class handloom products and are the largest commercial manufacturers of Eri or Ahimsa Silk in North Eastern India. Our products and services include Eri silk yarns, silk blended yarns and fabrics, made ups for both fashion and home furnishing.

Vision:

Prioritizing on issues such increasing women empowerment and fair trade practices has earned the company the recognition of a social initiative. We believe that we are ‘the vehicles of change’ in terms of both technology and social harmony.

Working towards the socio-economic development of the region has been a prime objective of Fabric Plus. Over the years we have helped in the promotion of local resources and crafts, and by doing so touching over 55,000 lives indirectly. By using eri silk and the art of handlooms as a vehicle of socio-cultural change, we believe that economic dynamism can be spurred in the region and livelihoods can be enhanced.

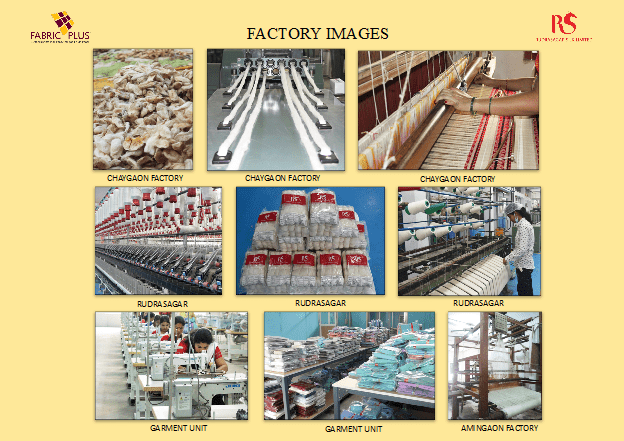

Fabric Plus’s production units are:

Spinning

The integrated Factory in Chaygaon, Assam, is one of its kind in the country, equipped with Japanese technology (imported from China), for the spinning of silk yarns (blended silk yarns), handlooms (combination of Jacquard, Dobby, Draw-boy, and a dyeing and decatizing plant.

Weaving

There are three weaving production centres besides six contract weaving centres, that enable us to produce a wide range of products for fashion and home textiles and customized products.

Apparels and Garmenting

With the commencement of their Garment Factory in January 2017, Fabric Plus has expanded its market reach even further. They are fit to serve as a brand manufacturer for garments in India & abroad. Led by a competent production team along with a design department, the factory holds 50,000 pieces production capacity for both knit & woven made-ups annually.