Prof. Tanveer Malik, Prof. Ajay Joshi and Prof T. K. Sinha

Shri Vaishnav Institute of Textile Technology

Shri Vaishnav Vidyapeeth Vishwavidyalaya, indore

ABSTRACT

The textile roots of microencapsulation technology were introduced as were the wide range of applications in food and other business sectors. In microencapsulation in general the number of commercial applications in the textile industry continues to grow particularly in the textile industries of Western Europe, Japan and North America. The move by the more developed countries into textiles with new properties and added value, into medical textile and technical textiles for example has encouraged the industry to use microencapsulation processes as a means of imparting finishes and properties on textiles which were not possible or cost-effective using other technology. Textile manufacturers are demonstrating increasing interest in the application of durable fragrances to textile as well as skin softeners. Other potential applications include, insect repellents, dyes, vitamins, antimicrobials, phase change materials and in specific medical applications, antibiotics, hormones and other drugs. Examples of each technology are described. A short summary of a new microencapsulation technology with roots in the textile industry, is provided.

KEYWORDS: Microencapsulation; Textiles; Fragrance; Phase-change materials.

INTRODUCTION:

Microencapsulation

Small is better” would be an appropriate slogan for the microencapsulation, a process in which tiny particles or droplets are surrounded by a coating to give small capsules with many useful properties. The material inside the microcapsule is referred to as the core, internal phase or fill, whereas the wall is sometimes called a shell, coating or membrane. Most microcapsules have diameters of few micrometres.

The reasons for microencapsulation are countless. In some cases, the core must be separated from its surroudings, as in isolating vitamins from the deteriorating effects of oxygen, retarding evaporation of a volatile core, improving the handling properties of a sticky material, or isolating a reactive core from chemical attack. In other cases the objective is not to separate the core completely but to control the rate at which it leaves the microcapsules as in the controlled release of drugs or pesticides. Manufacturing costs are based on coating material, solvent, equipment and labor. Coating-material prices vary greatly, and as a rule, the cheapest acceptable material is used. Coatings that can be applied without solvent or water are preferred. Enviromental and safety regulations greatly increase the cost of process that use volatile organic solvents.

Objectives of Encapsulation

Encapsulation of active ingredients for a wide range of industries is carried out for one or more of the following purposes:

- Rendering liquids into powders to prevent clumping and improve mixing.

- Protecting active ingredients from oxidation, heat, acidity, alkalinity, moisture or evaporation.

- Preventing ingredients from interacting with other compounds in the system, this may result in degradation or polymerization.

- Masking the taste of unpleasant flavors or odors.

- Improving the handling of an ingredient before processing.

- Release active chemicals in a controlled or targeted fashion.

- Protecting workers or end users from exposure to hazardous substances.

Microcapsules Structure

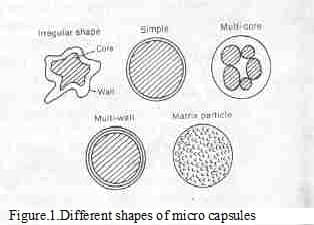

Microcapsule consists of two parts, viz. the core and the wall material. The typical range of capsule content is 70 to 99% nucleus material by weight. This corresponds to a capsule wall thickness of about 0.1-200mm. Different shapes of micro capsules is shown in Figure.1

The content of capsules can be made available by mechanical rupture of the capsule wall, by causing its disintegration by electrical or mechanical means or by leaching action carried out in an appropriate liquid environment. Microcapsules range in diameter from 1 to 1000 mm; capsules greater than 1000 mm can be called microcapsules and those smaller than 1 mm are called nanocapsules.

CHARACTERISTICS

The following are the characteristics of a microcapsule:

- Size and size distribution

Low size increases the mechanical strength as also ease of application

- Loading fraction

This is the weight ratio of core to wall of the microcapsule, the higher is this ratio the better is the production efficiency but poorer would be the stability.

- Release properties

Rate of release from microcapsules depends largely on the structure of the polymer wall, which in turn is influenced by the conditions employed in the preparation. Wall characteristics like crystallinity, cross-link density and porosity play a big role in determining the release rate. As the crystallinity and cross-link density of the wall increases, the release rate reduces substantially.

- Thermal stability

The microcapsule during its formation and application should be stable at higher temperatures.

APPLICATION OF MICROCAPSULES IN TEXTILES

The move by move developed consumer demands for textiles with new characteristics and added value into medical and technical fields has encouraged the industry to use microencapsulation processes as a means of imparting finishes and properties to fabrics which were not possible or cost-effective using other technology. Textile manufacturers are demonstrating increasing interest in the application of durable fragrances to textile as well as skin softeners; other potential application includes insect repellents, dyes, antimicrobials, phase change materials.

MICRO-ENCAPSULATION IN FINISHING

Micro-encapsulation of Flame Retardants

Textile coating with polyurethane resin on cotton or cotton-polyester fabrics provides the fabrics, properties such as abrasion resistance, water repellency, etc. which has application in many fields such as transportation industry, garments, furniture, but these polyurethane coatings have a bad flame retardancy. Microencapsules of di-ammonium hydrogen phosphate with polyurethane shell has been evaluated as fire retardant intumescent agent in a commercial polyurethane coating for textiles. This is achieved by melt spinning and interfacial polymerization. New approaches are developed at Gemtex for flame retarding textiles. Micro-encapsulation of phosphates as intumescent additives, PU/clay hybrid as FR coating, PA-6/clay nanocomposite as FR yarn and blends of wool with high performance Fibres as heat and fire resistant barriers are investigated.4

Micro-encapsulation in Medical Application

Micro-encapsulation has also found use in aromatherapy. Aromatherapy is the practice of applying and inhaling essential oils from plants as a physical and emotional boost to the body. An aromatherapy product manufactured by Kanebo is marketed under the trade name Esprit de Fleurs. Agatex has developed a technology to microencapsulate functional oils like the vitamins and Aloe Vera plant extract and use in textile finishing. It gives energetic balance to human body and also makes the fabric soft and comfortable. Number of companies has developed a technology of microencapsulating liposomes on the textile substrate which would yield controlled and targeted release of anti-cancer and anti-fungal drugs.

Micro-encapsulation of Anti-microbial agents

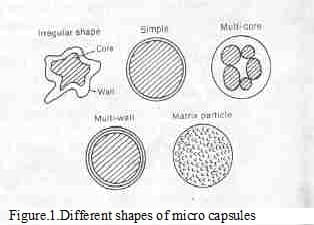

Anti-microbial agents are incorporated with the textile material to prevent the transmission of pathogenic microorganisms. In addition to this, antimicrobial finishes should be capable of counter attacking the development of odour from the bacterial decomposition of perspiration in clothing. Yeast cells containing biocide or insecticide have been applied to cotton, cotton wool and wool fabric. Fabrics with biocide filled yeast have been successfully tested as per AATCC Test method 100, a microbial challenge test. Mothproof agents have also been encapsulated in yeast and applied to wool fabric is also shown in figure.2.

Micro-encapsulation of fragrance

Our sense of smell is the strongest of our 5 senses; it is the one sense which does not rest even when we sleep. When our nose detects a change in the atmosphere around us it draws on our brains a vast memory bank to identify that change. Once identified we may be excited, soothed, relaxed, comforted, refreshed, revitalised or even alarmed. Utilising the sense of smell by building a fragrance into a textile or garment can stimulate a powerful and emotive sense. Fragrances can range from fine fragrances, florals, fruits, and malodour counteractants until aromatherapy.

Body odour, Freshness Technology Fragrances for textiles

When we sweat our body chemicals mix with bacteria, which produce enzymes. It is these enzymes, which lead to the formation of body odour. Freshness Technology fragrances are fragrances that smells good and actively tackles body odours.Quest offers a number of different patented technological routes to achieve an extra freshness in textiles. Each of these routes, whilst working on different principles, will actively tackle any bad smells rather than just masking them. All their freshness technology fragrances are created using only the normal perfumery ingredients conforming to the highest safety standards as set out in the fragrance regulatory bodies such as IFRA and RIFM. Expert panels and clinical and consumer testing facilities are in place to validate the freshness achieved with the use of their freshness Technology Fragrances.

Skincare Active Ingredients for Fabrics

Adding skin benefits to a textile is achievable by applying encapsulated moisturisers, essential oils, certain vitamins and even insect repellent. The use of encapsulated cosmetic oils is especially recommended to add skin benefits to hosiery, nightwear and sports wear. Aleo Vera has been known for centuries as the medical plant whose properties contain a wide range of healing benefits.Today the extract from the Aloe plant is a population constituent of cosmetic preparations. Throughout the world today there are some 600-700 different varieties of aloe. The most widely used in cosmetic industry is Aleo Barbadensis. Its common names are First aid plant or Medicine plant.

The plant grows wild in Barbados, Jamaica, Puerto Rica, in the southern USA, Central America, Mediterranean countries, India and other tropical and sub tropical regions. Aloe Vera gel is extracted from the inner tubular leaf cells of the Aloe Vera leafs. The main constituents of Aloe Vera are amino sugars, amino acids, enzymes, inorganic salts, monosaccharides, mucopolysaccharides, sterols, triterpenoids and vitamins. The use of Aloe Vera in cosmetics is especially recommended because of its positive effects on skin.

Benefits of Aloe Vera:

- Bacteriostatic effect

- Anti inflammatory effect

- Moisturising effect

- Regenerate and promotes suppleness of the skin

- Protects, soothes and cares for the skin

- Beneficial effect on the blood circulation

Insect repellents

Menthoglycol is a natural insect repellent active ingredient, derived from lemon eucalyptus, which is a natural and renewable source. Testing of Menthoglycol with a moderately aggressive cage population of Aedes aegypti mosquitoes resulted in no bites up to at least 4 hours. This indicates that the product has unusual repellency Fabrics treated three months previous with microencapsulated menthol glycol completely repelled foraging mosquitoes in nature, in exposure conducted over a four hour period. This finding is consistent with those obtained with the same fabric at about one week after its treatment with the test material. The result indicates that mentholglycol persisted on the fabric for the three-month storage period. Concordant with this view, rubbing of the fabric released the menthol glycol.

In summary the outcome of this test certainly suggests that micro encapsulation may greatly extend the effective lifespan of the mentholglycol insect repellent.

Commercial opportunities

Imagine the functionality of body odour counteractancy coupled with your choice of a smell specially designed to reinforce your concept to the consumer. All the freshness technology fragrances are bespoke and are created by perfumers to echo the emotional benefits of your brand. Perhaps you or your customer may wish to have a signature fragrance developed specifically for your product range. Fragrance in a product or promotion leads to an improvement of sales. As example, post cards were recently used in a promotion for a new oral hygiene product. The promotion used a redemption or discount voucher. A typical increase in sales would be between 0.8 & 2 percent. By using the product fragrance on the promotional material this was increase to 8 percent. The second example is a promotion for Radion detergent for Lever Brothers, where the product fragrance was used on promotional material; sales were raised by 13 percent. There are several novelty markets for fragrance usage; just one example is the children’s markets. 30 % of women are unable to wear hosiery due to the nature of the garment which dries their skin. Applying micro-encapsulated Aloe Vera to the hosiery during the wet processing of manufacture overcomes this problem and opens up a potentially enormous new market. One of Coalescence’s clients is currently using in excess of 1 tonne of encapsulated Aloe Vera per month just for this application.

Micro-encapsulation leads to a lot of opportunities which could result in an increase of sales and market share. The challenge to compete in the high competitive textile market can be accomplished by diversification and by obtaining a first mover advantage in the development and the commercialisation of new innovative textiles with a real and functional added value to the customer.

Most frequently used wall materials are urea formaldehyde and various forms of gelatin in micro-encapsulation of fragrance. The capsule size should be small conventionally. Fragrant fibrous materials have also been produced by Kanebo that consist of perfumes bound to a variety of fibres using a low temperature reactive organopolysiloxane resin. As silicone binders are used, no unpleasant odours of binders interfere with the desired fragrance. Proctor & Gamble has prepared microcapsules using urea formaldehyde as the shell material containing perfumes or deodorant material. Welbeck Fabrics introduced scented fabrics CX series. These fabrics have wide range of scents and also lasting upto 40 washing cycles. Microcapsules has been developed and manufactured by RT Dodge for several years. The company also claimed that microcapsules survive upto 8 – 20 washing cycles and are strong to conventional tumble-dryers. Celessence International has produced microcapsules for textiles and launched in the market under the trade name Celessence TXT capsule systems which can be applied by conventional textile application methods to a wide variety of textile substrates. The product claim encapsulation of skin moisturizers, vitamins and insect repellents as well as fragrances which can last upto 30 laundering cycles. Celessence TXT capsule systems comprise aqueous dispersions of encapsulates, which can be applied by pad, exhaustion or hydroextraction technique to a wide variety of textile substrate. Durability to washing and handle may be further improved by incorporating suitable formaldehyde-free binders and softeners.

The Matsui Shikiso Chemicals Company has developed a technique of fixing fragrance to fabric using microcapsules. The fabric is first treated with a nitrogenous cationic compound and the microcapsule wall is manufactured to adhere to this layer. The capsules are obtained by using interfacial or in-situ polymerization. These capsules range in size from 0.1-100 mm. Typical compounds encapsulated include perfumes such as musk, civet, ambergris, pine and citrus oils. LJ Specialities has developed microencapsulated fragrance products for textiles. The mechanism of aroma releasing depends on the light abrasion and can be applied using conventional methods. Eldorado International Company has produced fabrics that contain encapsulated aromas. The capsule breaks on abrasion caused by the wearer. Haketal has developed a technology of using beta cyclodextrin as a wall material. Beta Cyclodextrin was grafted onto cellulose fibres using N-methylol acrylamide. Hong and Park prepared microcapsules using melamine-formaldehyde systems containing migrin oil. They also suggested poly(L-lactide) as a wall material to encapsulate fragrance for textiles. Poly(L-lactide) micocapsules containing fragrances were prepared by interfactial precipitation method. Adding skin benefits to a textile is achievable by applying encapsulated moisturizers, essential oils, certain vitamins and even insect repellent products. For sportswear it is even possible to use skin-cooling products.

So imagine being able to capture virtually any fragrance and harness it to your benefit, and you will realise that nothing is as emotive as the sense of smell. It is a challenging and an exciting time for the textile industry. Micro encapsulation is a finish with an added value, which could expand market territories or create niches and lead to an improved market share. We also offer the possibility for brands to develop an exclusive signature fragrance to increase their recognition through the marketplace.

MICROENCAPSULATION: THE FUTURE

The ideal feature for most textile applications using microcapsules would be a system that is easy to apply, does not affect the existing textile properties and has a shelf-life on a garment that allows normal fabric-care processes to take place.Currently, although capsules can survive 25–30 wash cycles, conventional ironing and other heat-input processes such as tumble-drying can cause a dramatic reduction in the desired effect. The microencapsulation industry must take more notice of the possibilities within the textile industry and specifically design microcapsules that overcome these problems.

For the future, the consumers desire that novel and unique effects will always be present. But more importantly, in an ever-increasing desire for convenience, the consumer will require that fabric properties are inherent in the garment, e.g. fresh odour and softness. Consumers will expect these properties to last the lifetime of the garment, and not involve routine intervention in the form of the never-ending addition of washing aids and fabric conditioners. Microencapsulation may deliver these long-term goals. The desire for a healthier and more productive lifestyle will continue to generate a market for textiles that promote “well-being”. Textiles that “interact” with the consumer, reducing stress, promoting comfort and relaxation, are possible through active delivery from microcapsules. In the last decade the textile industries have concentrated on developing performance fabrics with added value for sports and outdoor application, as well as novel medical textiles.

Microencapsulation can play a part in this continued development, for example by allowing sensing chemicals to be attached to sports clothing and medical products; these will be able to warn of damage or hazard to the wearer. Systems can also be developed that deliver measured dosages of chemicals to combat muscle pain or other more serious injuries. The potential applications of microencapsulation in textiles are as wide as the imagination of textile designers and manufacturers. Early success for some companies in producing microencapsulated finishes for textiles have come about from collaboration and adaptation of technology from other industrial sectors.

REFRENCES:

- CHEMICAL FINISHING OF TEXTILES- H.SCHINDLER

- TEXTILE FINISHING- MARS,ATLAS & WOODING

- COLOURAGE- Mar 2006

- INDIAN TEXTILE JOURNAL – Feb 2007