ABSTRACT

Laser cutting is meanwhile being used for a wide range of materials across all sectors of industry. This cutting method offers an efficient alternative to conventional processes both for short runs and for industrial mass production runs. Thus, the contactless processing represents a crucial argument for the textile industry. An increased number of applications can daily be recognised for the usage of this technology in the textile market.

A large number of filter media based on relatively cheap non-woven fabrics are in fact technical textiles and can generally be formed easily using knives or cutting tools. However, as soon as filter processes are integrated in changing operational processes, small or medium-sized quantities soon become necessary and it is here that production quickly reaches its limits where flexibility is concerned. The capacity for individual fabrication of filters and large filters as well as the immediate availability of the materials to the operators are crucial arguments for the use of laser technology. Besides, especially the contactless processing through the laser beam and the therewith related non-deforming cutting plays an important role. So, a high precision in processing will be achieved.

With their specialisation in using CO2 laser systems for cutting non-metallic materials, the company eurolaser GmbH has firmly established itself on the world market. Today, automations for the textile processing are indispensable for an economical production. Thus, eurolaser applies the Conveyor System for roll material. By using this automatic material feed, textiles can be fed for laser cutting directly from the roll and routed after laser cutting directly to a table extension. With a high degree of connecting accuracy after a material feed cycle, sections, which for all practical purposes are endless, can be produced. The bale material is fed via an automatic feeding unit. A feeding system edge controller ensures precise positioning of the material. Further, there is even an option to add a winding unit to the Conveyor System. This is used for the even winding of previously processed textiles and this accordingly results in a completely automated cutting process.

Laser technology in the textile industry – more production flexibility

Laser cutting is meanwhile being used for a wide range of materials across all sectors of industry. This cutting method offers an efficient alternative to conventional processes both for short runs and for industrial mass production runs. Thus, the contactless processing represents a crucial argument for the textile industry. An increased number of applications can daily be recognised for the usage of this technology in the textile market.

Today, modern woven fabrics, spacer fabrics as well as multilayers, fleece and needle fleece, but also glass fibre fabrics, thermo-resistant and additional technical textiles will be cut by laser. Especially the contactless processing through the laser beam and the therewith related non-deforming cutting are crucial arguments for the use of laser technology. Besides, the high precision of up to the 1/10 mm area represents an important aspect. The tool ‘laser beam’ does not have any tool wear, as well as no any work piece fixing is required. Furthermore, laser processing reduces or eliminates fraying in particular in case of cutting mixed fibres. Consequently, corresponding measures for post-processing and cleaning do not need to be considered anymore. Additionally, the undesirable formation of dust is a thing of the past

20 years of experience in laser processing

With their specialisation in using CO2 laser systems for cutting non-metallic materials, the company eurolaser GmbH has firmly established itself on the world market. Founded in Hamburg in 1994, eurolaser, now with approximately 100 employees, is one of the world leaders in CO2 laser systems for cutting non-metal materials

One of the core markets for the laser systems are companies which are processing acrylics, such as displays, labels and lettering. An even bigger market is that of cutting plastic foils. The automobile industry, front panels for household appliances and keyboard foils -all play a leading role here. Another trend in the use of laser cutting systems has been identified over the past few years. The textile market is developing exceptionally strongly. This includes technical materials, e.g. from filter mediums to plush fabric for the toy industry. The CO2 laser systems are being increasingly used in a range of industries for cutting and engraving

The expandability of the laser systems has always been a top priority during development. Also the new models are designed according to a modular principle to ensure users are always provided with the right solution for their special applications. What is particularly interesting is the possibility of using mechanical tools parallel to laser in order to increase the processing flexibility even further. For this purpose there is a complete range of high-quality tools from Zünd Systemtechnik AG from Switzerland available to the customer. In addition to milling tools, numerous knives, creasing, marking and cutting tools are available. This makes it possible to ideally combine the advantages of a range of different processing methods in just one single machine

High-end laser cutter for technical textiles

The laser system manufacturer eurolaser GmbH, located in Lüneburg (Germany), provides a special laser system for especially large textiles. With the ‘New Generation’ 3XL-3200, now even wider textile sheets up to 3,210 mm width can be processed

Today, automations for the textile processing are indispensable for an economical production. In this case, eurolaser applies the Conveyor System for roll material. By using this automatic material feed, textiles can be fed for laser cutting directly from the roll and routed after laser cutting directly to a table extension. With a high degree of connecting accuracy after a material feed cycle, sections, which for all practical purposes are endless, can be produced. The bale material is fed via an automatic feeding unit. A feeding system edge controller ensures precise positioning of the material. Further, there is even an option to add a winding unit to the Conveyor System. This is used for the even winding of previously processed textiles and this accordingly results in a completely automated cutting process

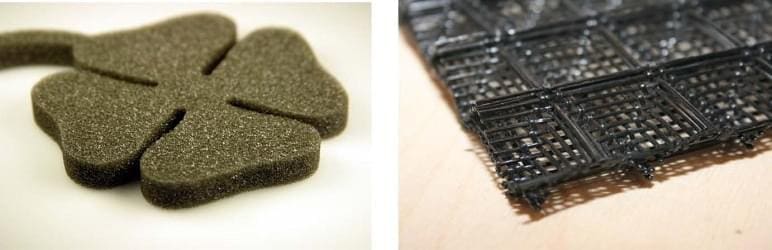

A special table concept is used for textile machining. This comprises a stainless steel wire mesh and is particularly suitable for thin and flexible materials. On the one hand, this is used as the material support for the machining process and, on the other hand, the transport element for the Conveyor System

Furthermore eurolaser offers an Ink Marker for all laser cutting systems -an extra option that can be retrofitted. The demand for simple, economical and contact-free marking methods is growing continuously, particularly for sewing markings (clippings) in the textile manufacturing branch. The universal jet system operates with compressed air and is supplied via an easy refillable ink cartridge. Materials such as polyester, polypropylene and acrylic plus almost all natural textiles, can be marked with the adjustable jet (2-4 mm line width)

Furthermore eurolaser offers an Ink Marker for all laser cutting systems -an extra option that can be retrofitted. The demand for simple, economical and contact-free marking methods is growing continuously, particularly for sewing markings (clippings) in the textile manufacturing branch. The universal jet system operates with compressed air and is supplied via an easy refillable ink cartridge. Materials such as polyester, polypropylene and acrylic plus almost all natural textiles, can be marked with the adjustable jet (2-4 mm line width)

A clean cut -modern filter cut by laser

The filter, a product continuously gaining in importance in all respects. Filters – originally ‘to pass through a porous material’ are indispensible for mechanic separation. Wherever products are manufactured, their quality positively improved or a simple selection carried out, a filter is the means to the end. Filters have proved simple but effective for hundreds of years and played an important role in industry during the 19th and 20th centuries. There was a continuous revolution in progress with regard to the filter media during this time. This was due to knowledge gained about new materials on the one hand and change driven by increasingly higher dissolutions in analytics that led simultaneously to higher demands on the filter medium on the other hand

There is no doubt about it -the manufacture of modern filters is certainly an important issue. All in all, the filter has become a significant medium in our times. Nowadays everyone is well informed, well-read and aware his rights where quality and health are concerned. Modern filter media are used for the separation of process by-products. However, frequently, the separated material is also the desired product.

Thus, the filter media used, in this case the filter fleece, must be structured accordingly. In voluminous filter fleeces, suspended and ultra-fine particles are deposited in the fibre labyrinth, increasing the filtration level

Non-woven fabrics for filters

One of the uses of filter fleece is the separation of solids from liquids in wet filtration. So high-quality filters for the food industry are just as much scrutinized as filters for ventilation and exhaust technology. Whether for underground ventilation for mines or for the air supply in the interior of cars -nowadays separating pollutants and fine particulate matter, even down to the sub-µm range, presents no problem at all. Progress due not only to the filter material but also to processing methods. In many applications, the material is fabricated to suit specific technical processes, some of which are in continuous operation. The capacity for individual fabrication of filters and large filters as well as the immediate availability of the materials to the operators are strong arguments for the use of laser technology

Laser processing – contactless and clean – makes it possible. A large number of filter media based on relatively cheap non-woven fabrics are in fact technical textiles and can generally be formed easily using knives or cutting tools. However, as soon as filter processes are integrated in changing operational processes, small or medium-sized quantities soon become necessary and it is here that production quickly reaches its limits where flexibility is concerned.

Today, even an individual filter fabric can be produced automatically by machine within a few minutes. The focussed light of the laser can cut a multitude of nonwoven fabrics with consistently high precision, without any preparatory measures. Application of the laser cut is as clean as it is simple. There is no need to create a tool and no tool changeover. Thus, there is no wear on the cutting blade. Beside, you do not even have to clamp the material.

This New Generation is necessary if the high demands of industry and processors placed on the manufacturers of filters are to be met. eurolaser systems can handle short delivery times, efficiency even with low quantities and dimensions of up to 3,210 x 3,200 mm with no problem at all. In order to ensure that serial production can also be run profitably, we now offer conveyor production systems. Laser is the tool. Thanks to a sophisticated system technology, al single processing steps, such as material transport, recognition, positioning and material cutting are carried out fully automatically for the most part. Material handling has such a wide range that light to heavy materials can be transported to the laser with equal accuracy. The CO2 laser beam – a laser that emits in the infrared range – is focussed above the material to be processed and hits the surface of the material at a point of 2/100 mm2 and with a power of 100 to 400 watt. Exposed to such a concentration of energy, most materials sublime within fractions of a second. A process gas is introduced – usually simple compressed air of approx. 2-3 bar – in order to accelerate the cutting process and ensure clean cut edges. The cutting emissions in the form of smoke are evacuated to 100%, filtered and discharged to the exterior. No frayed material, chippings, flakes or threads remain on the manufactured part. As a rule, the ‘lasered’ product is ready for further processing without the need of any post processing.

In this situation, the cutting of the filters with a laser cutting system offers many advantages.

Automatic welding of the cutting edges prevents fraying

No tool wear -no reduction in quality

High flexibility in daily use of the laser system through numerous additional

options

High precision and repetition accuracy

Virtually dust-free cutting

Optimal material utilisation

No application of force through stretching or punching

Large format cutting, by considering a roll width of up to 3,200 mm

Optional automatic material feed and removal

It was around the turn of the millennium that the non-woven filter industry began investing in laser technology. Today, a sophisticated system technology is available at a comparatively low investment cost. In its own application lab, eurolaser demonstrates how this technology is used for filter materials. Interesting discoveries and a pending new generation of non-woven fabric processing are leading to higher productivity. On all accounts, it is certainly worthwhile making a comparison and ordering a trial sampling