Vishnu Pareek1 Nikhil Bhosale1, Aayushi Agrawal1, Shrikant Eklahare2

Department of Diploma in Fashion and Clothing Technology, DKTE Society’s Textile & Engineering Institute – Ichalkaranji

Department of Textile, Faculty of Finishing, DKTE Society’s Textile & Engineering Institute – Ichalkaranji

Email Id:–vishnudkte@gmail.com , vishnupareek.tex@gmail.com

BlogSpot: https://vishnu-pareek.blogspot.in/

ABSTRACT

Fragrance finishing of textile materials has been greatly expanded and used in recent years. Fragrance finishing can be done effectively using exhaust method than any other methods. If the fabric is treated with fragrance agents which exhibits higher durability of functionality is estimated. Fragrance finishing can be done by means of lavender aroma with non-ionic binder. This paper examines the effects of fragrance finished aloe-vera and cotton fabrics. Finally both the fragranced finished fabrics were made into wall hangings and the ambiance of the room was evaluated by comparing various factors. In this investigation, factors such as fabric performance, durability of the fragrance and laundering properties of the treated fabrics were investigated. The fragrance finished fabrics can be used in home textile applications such as wall hangings, table covers, carpets and sofa covers.

Keywords: Fragrance Finishes, Cotton Fabric, Aloe-Vera Fabric, Lavender

INTRODUCTION

Gone are the days when quality product was the only criterion to eye a product by a consumer. Earlier were the times when sheer competitiveness in the domestic market was very confined. But, during some past years with the emergence of globalization, competitive atmosphere and quality consciousness, has reached a new mark. With the steady improvement in technology & application standards, a gradual rise was observed in consumer demands and to reach up to that mark, manufacturers have to add something to their products to get market value for their products. A product must be able to encompass something more with it & therefore this has taken today’s market to a platform where it seems very difficult for a manufacturer to market his product until he satisfy the consumer with something new which not only rewards him for his novel concept but also lures him with considerable increase in profit . The role of the textile finisher has become increasingly demanding, and now requires a careful balance between the compatibility of different finishing products and treatments and the application processes used to provide textiles with desirable properties. Growing trends and escalating standards leave no stone unturned to boast the current scenario of textile industry. Performance with beauty describes the potential of textile finishing. Fragrance finishing of textiles is one such immaculate magnanimous entry into any textile culture. Fragrance finishing of textiles is the process where we enhance the value of the product by adding some incentives to it. The world market place is continuously changing and so is demand of people changing .Every person desires for some change .i.e. something new & unique. The successful effective implementation of change has to be done to in the market. We by the medium of this paper have made an earnest attempt to present you a detailed comprehensive analysis done by fragrance finishing and which has busted this industry with exuberant value added finish with the incorporation of different scents into fabrics, leading to the production of scented fabrics and the psychology of acceptance of synthetic scents in textile goods.

TECHNOLOGY FOR FRAGRANCE FINISHING (MICROENCAPSULATION)

Microencapsulation is a natural phenomenon and the examples of ideal microcapsules are found in the nature i.e., spores, seeds, eggs and pollen etc only a few to mention. Due to numerous applications of microencapsulation and as a result there are a number of processes developed to encapsulate a galaxy of materials to suit the individual applicability. In the broadest sense, microencapsulation provides a means of packaging, separating and storing solid and liquid materials in a microscopic scale for a later release on your own desire under controlled conditions.

The fragrance compound and the essential oil are volatile substances. The most difficult task in preparing the fragrance emitting textile is how to prolong its lifetime of Adour. Micro-encapsulation is an effective technique to solve this. Microcapsules are minute containers that are normally spherical if they enclose a liquid or gas, and roughly of the shape of the enclosed particle if they contain a solid. It can be considered as a special form of packaging, in that particulate matter can be individually coated for protection against environment and release the volatile substance from the enclosed capsule as required. This property has enabled microcapsules to serve many useful functions and find applications in different fields of technology. For example, the storage life of a volatile compound can be increased markedly by microencapsuling. The key to aromatic textile is how to make microcapsules of fragrance com-pounds and essential oils without omitting any ingredient in order to ensure its effects. In addition, using a low-temperature polymer binder to attach a perfumed microcapsule to the surface of the textile is also an important part of preparing an aromatic textile. At the same time, durability in laundering and a soft handle should be carefully considered

Why Use Microencapsulation Technology

1. Protection of the enclosed material and improved storage life.

2. Conversion of a liquid component to a dry solid system.

3. Ensuring separation of incompatible components.

4. Odor masking, dust control and pH control

5. Controlled diffusion of active components through the shell as for example in delayed drug release.

Applications :

» Cosmeto-textiles

Microencapsulated skin moisturizers, vitamins and provitamins are applied in garments and known as cosmeto-textiles, designed for wear in contact with skin. These are claimed to promote a younger look, counteracting the effects of skin ageing, e.g. as a result of exposure to UV-radiation. There are also microencapsulated preparations for skin cooling.

» Aromatherapy Textiles

The uses of aromatherapy textile are diverse. Interior textiles such as sheets, quilt-covers, curtains, carpets and bed-gowns are suitable for the attachment of lavender, camomile, citrus or cinnamon microcapsules, which are good for hypnogenesis and eliminating fatigue. Patients suffering high blood pressure feel sedation when they use a pillow made of fabric treated with lavender, basil, and lemon or fennel microcapsules. The tired office clerk wearing clothing with a scent of lemon rose, or jasmine oil may find his work efficiency improved. Meanwhile, it is convenient for dermatitis sufferers to be cured with the aid of underwear containing killing gem fabric. Perfumed toys make it easier for children to get closer to nature. Generally speaking, varied per-fume fabrics create good opportunities for customers to make the ‘cocooning’ environment they prefer to live in

» Home Textiles

In other areas, household textiles such as curtains, sofas, cushions, sheets, as well as apparel items such as gloves, socks and ties may also be treated with microencapsulated fragrance and deodorizing finishes. The carpets can be finished with fragrances of different kinds and can be widely used in home textiles as well as automotive textiles.

» Sport Wears

As the ‘second skin’ of the human body, all types of textile are excellent media for transferring fragrance compounds, and are essential to people in sport according to their preference for them. The type of the fragrance necessary for sports wear may be orange, lemon which will keep them energized on the ground for longer period

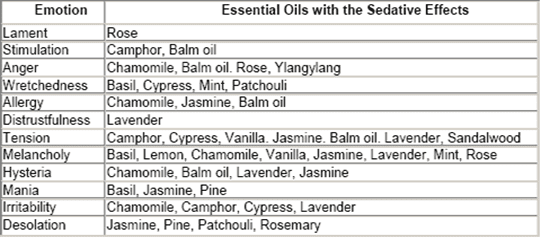

Fragrances and Human Emotions

Process for Fragrance Finishing

Weaving

In the weaving process, the fabric is woven by plain weave with 60 ends per inch (EPI), 48 Picks per inch (PPI) and the yarn count used is 20s Ne (100 % cotton).

Desizing

Both the cotton fabrics are treated with de-sizing process for removing starch size. The fabric is padded with malt extract enzyme (3-5%) at 60°C by using 1:20 material to liquor ratio with pH 6-7. Finally the material is washed, squeezed and dried.

Scouring

After de-sizing the fabrics are treated with scouring process for remove the natural and added impurities present in fabric such as natural oils, wax, pectins, proteins, mineral matters, dirt etc. The fabric is treated with NaOH (2-3gm/l) and (2-3gm/l) non-ionic surfactant at 100°C for two hours by using 1: 20 material to liquor ratio with 12 pH. Finally the material is washed, squeezed and dried to get better absorbency.

Printing

The fabrics are printed with pigment colours by using direct style roller printing machine. And the fabrics were dried at 100°C, cured at 150°C for 4 to 5 minutes. Finally the fabrics are washed with 2% non-ionic surfactant and dried.

Methodology

- Fragrance Finishing

Fragrance finishing is the process of imparting aroma in any textile substrate. This is done by exhaust method which means, fragrance agents is applied on both the cotton fabrics with the help of binder. Lavender fragrance was taken as a flavor for this process.

- Preparation of Recipe

The lavender fragrance agents with binder ST were formed by mixture solution containing alcohol and distilled water with ratio (1:3). The solution was emulsified with a high-speed mixer at a speed of about 10,000 rpm for 5 minutes. The emulsified system was transferred into a flask. The alcoholic fragrance solution was added into the emulsified solutions over 30 minutes, and stirred at a temperature of 40°C for 2 hours.

- Finishing Process

Fragrance finishing was given to the fabric by exhaustion method with 5-7% binder ST which is used as cross-linking agent. The fabrics were kept immersed in the solution containing lavender fragrance, (ML ratio – 1: 10) for 20-30 minutes at 40ºC in water bath. After finishing, the fabrics were removed, squeezed and dried at 100ºC in the oven for 5 minutes and then cured at 120 ºC for 2 minutes

Conclusions

Fragrance finish is the process by which textile materials are treated with the pleasant odors which yields better beneficial effects. The pleasant smells can be created by the essential oils have pharmacological effects like antibacterial, antifungal, antiviral, etc. and mood elevating effects. The fragrance of lavender

proves good way to meet important psychological and emotional needs, as well as those of a purely physical and sensorial nature. Thus by comparing the laundering durability results, it justifies that fragrance finished aloe-vera fabric has better laundering durability. Comparing the sensorial effect of fragrance intensity, it justifies that fragrance finished aloe-vera fabric has better sensorial effect of fragrance intensity. Then based on the washing fastness results, it justifies that fragrance finished aloe-vera fabric has better adjacent fabrics staining rating than cotton fabric. Comparing the light fastness rating, it justifies that fragrance finished cotton fabric has slightly better light fastness rating than aloe-vera fabric. Based on the wick-ability results, it justifies that wick-ability were good for both fabrics. Finally based on the overall performance it is concluded that the fragrance finished aloe-vera fabric is better than cotton fabric for wall hanging (curtain) and in all home textile applications.

REFERENCES

- Aromachology and its Application in the Textile Field -C. X. Wang, Sh. L. Chen , Fibres & Textiles in Eastern Europe January / December 2005, Vol. 13, No. 6 (54).

- Capture and Controlled Release of Fragrances by CD Finished Textiles – B. MARTEL, Journal of Inclusion Phenomena and Macrocyclic Chemistry 44: 439–442, 2002.

- Odor Measurement in Textile Industries – Krzysz Gniotek , Fibres & Textiles in Eastern Europe January / March 2003 Vol. 11 No.1 (40).

- Scent-Infused Textiles to Enhance Consumer Experiences John Pierce, leader; Fernando Tovia; Natalie Weathers (Phila U) National Textile Center Research Briefs – Fabrication Competency: June 2006.

- https://www.fibre2fashion.com/industry-article/textile-industry-articles/fragrance-finishing-of-textiles/fragrance-finishing-of-textiles1.asp

- https://article.sapub.org/10.5923.j.textile.20120103.01.html#Sec5