DKTE’S Textile Engineering Institute, Ichalkaranji, MH, 416115, India

S.S.Lavate, Aravin Prince P., Nitish Sarda, Rahul Gadkari,

Corresponding author Email address: saatishslavate@gmail.com

Abstract

Look deep into nature and you will understand everything—Albert Einstein

Can innovation be managed? The history of advancement shows that we depend on the vision and efforts of people going beyond what is considered rational or possible and seeing what happens. This is an orderly way of doing things in that it gives a framework. Think the unthinkable, then rationalize it and bring it into the common ambit. This is also what happens with biomimetics. Biologically inspired textiles are those that take ideas from nature and implement them in new fibres and fabrics. Biomimetics are increasingly being applied to new textile technologies. This collection draws together research to explain how biologically inspired technologies can meet the needs of industry for cutting edge textile designs and products.

In this review, we are borrowing concepts and designs from nature inspired details to incorporate in fabrics and apparel, riding on the wave of modern sciences and technologies.

- Introduction

Biomimetics – which we here mean to be synonymous with ‘biomimesis’, ‘biomimicry’, ‘bionics’, ‘biognosis’, ‘biologically inspired design’ and similar words and phrases implying copying or adaptation or derivation from biology – is a relatively young study embracing the practical use of mechanisms and functions of biological science in engineering, design, chemistry, electronics and so on.

In the early 1940s George de Mestral, a Swiss inventor, went for a walk in the forest with his dog. Upon his return home he noticed that the dog’s coat and his trousers were covered in cockleburs. His inventor’s curiosity led him to study the burs under the microscope, where he discovered the hooked ends of the bristles that stick out from the seeds. This became the basis for a zip, later developed into a two-sided fastener. One side has stiff hooks like the burs; the other has loops like the fabric of his trousers. The result was Velcro, named for the French words ‘velour’ (velvet) and ‘crochet’ (hook). The challenge was then to make machinery that could produce textured fabrics that would work reliably. After considerable experimentation, de Mestral developed special looms and hook-cutting machinery.

Smart and intelligent textiles are important developing area in science and technology because of their major commercial viability and public interests. Smart and intelligent textiles/materials can be defined as the materials and structures which can sense and/or respond to the environmental conditions or stimuli. Nature designed biomaterials have structure–functional capabilities that are beyond the reach of manmade materials like silk, leather and wool which are widely used to make clothing. If we are successful in harnessing bioinspired approaches to smart fabric design which can perform sensing and actuation, we might be able to create intelligent apparel which is currently considered as science fiction.

- Biomimetics and its applications in Textiles

This concept used in textiles many ways right from fibre forming to finishing stages for development of products for specific applications.

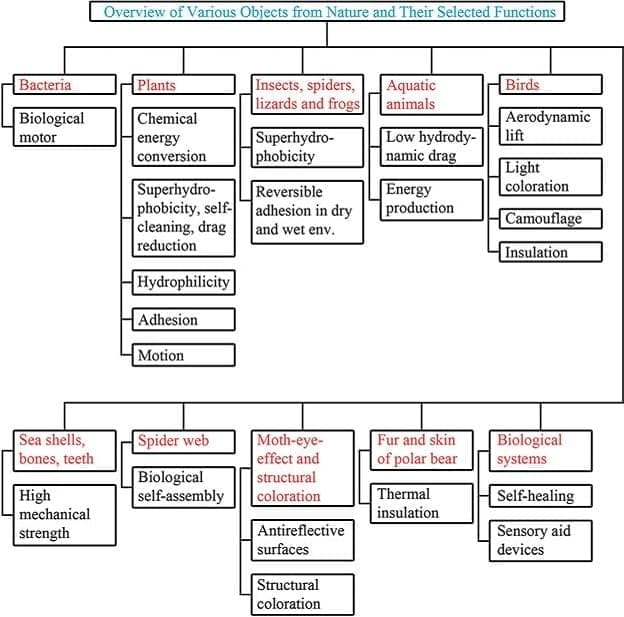

Fig: 1 An overview of various objects from nature and their selected function

2.1 Lotus Effect – Design of anti-dust, water repellent fabrics:

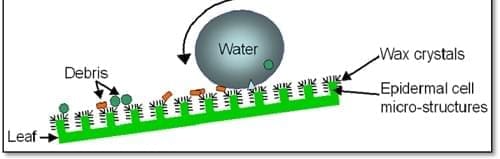

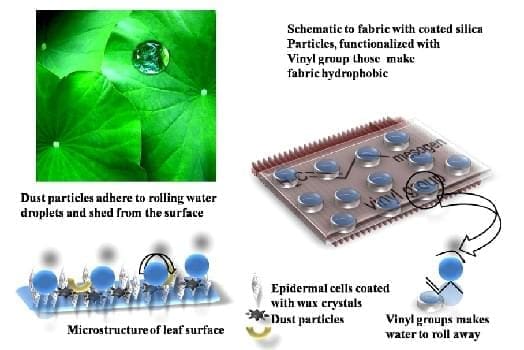

Fig 2 Lotus Effect

Ever clean, anti-dust and water repellent properties of glassy lotus (Nelumbo nucifera) leaf arise from its surface micro-topography, without detergent or spending energy. The plant’s cuticle unlike other plant is made up of soluble lipids, embedded in a polyester matrix – wax but the extreme degree of its water repellency arises due to special surface topography which provides super hydrophobicity. Micro topography of the lotus leaf exhibit extensive folding (i.e. papillose epidermal cells) and epicuticular wax crystals jutting out from the plant’s surface, resulting in a roughened micro- texture. This microarchitecture tend to reduce adhesive force on water droplets as trapped air in the interstitial spaces of the roughened surface result in a reduced liquid-to-solid contact area, making the lotus leaf surface less prone to adhere water and dust particles (Fig.3). Reduction in surface area between water–leaf’s microtopography over 95% (passing breeze) causes the water drops to roll off due to gravity, taking the attached dirt particles with them, and cleaning the leaf surface forever. Modern nano science and micro fabrication techniques are equipped with tolls and techniques to design such features artificially and incorporate it into fabrics to give water and dust repellent apparel.

Learning microtopography from aforementioned lotus effect, researchers have created superhydrophobic poly-lactic acid (PLA) fabrics via UV-photografting of hydrophobic silica particles functionalized with vinyl surface group over silica microstructure Advantage of the technique utilized herewith is that such models can be successfully integrated not only in PLA but also in fabrics, exhibiting a robust method to design water and dust repellent fabrics.

Fig: 3 Nature inspired lotus design into fabrics to mimic water and dust repellent apparel. Micro-topography with specialized wax coated epidermal cells (left) and, conventional design mimicking the anti-lotus effect into smart fabric design.

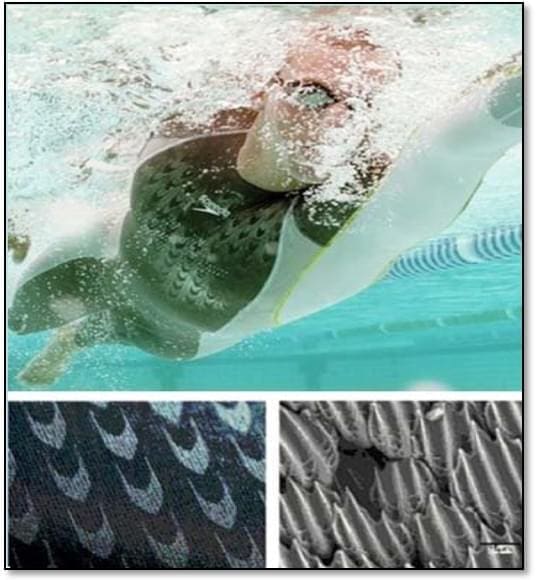

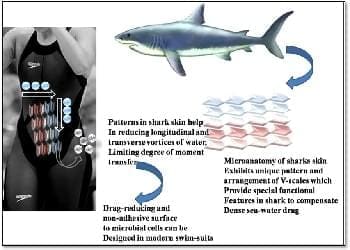

2.2 Shark skin inspired low hydrodynamic surface drag:

Most shark species (super order Selachimorpha) move in water with high efficiency and maintain buoyancy due to special ingenious anti-drag design of their skin which reduces drag by 5–10%. Scanning electron microscope studies have revealed the tooth-like scales of shark skin, called dermal denticles (little skin teeth or riblets) which are ribbed with longitudinal grooves (aligned parallel to the direction of local flow of water). It produces vertical vortices or spirals of water, keeping the water closer to the shark’s body, thus, reducing the surface drag (Fig. 4). This fine microstructure varies from one location to another depending upon the body part participating in hydrodynamic balance while swimming. The V-shaped scales approximately 200–500 mm in height and regularly spaced (100–300 mm), are present over most of the shark’s body.

Moreover, this microscale longitudinal ridges influence the fluid flow in the transverse direction by limiting the degree of momentum transfer and the ratio of scale height to tip-to-tip spacing has critical role in reducing the longitudinal and transverse drags. Another remarkable feature associated with this unique shark scale feature is its microtopography that acts as antibacterial fouling surfaces and microorganisms find it inhospitable to attach on such grooved surface. Inspired by natural design, scientists are adding technological improvements to swimming suits by designing antimicrobial fabrics without the chemical treatments. Especially in Olympic swimming competitions, 1/100th of a second can make the difference between winning and losing the event. Now such important sport events are heading towards technological support since swimmers are using swimming suit designed on the hydrodynamics principles of a shark’s skin.

These tightly fitting suits, covering rather a large area of the body are made up of fabrics which are designed to mimic the properties of a shark’s skin by superimposing vertical resin stripes. This phenomenon is known as the Riblet effect (Fig. 4). Swimsuits made with the new fibers and weaving techniques mimicking shark scales microfeatures, are produced to cling tightly to the swimmer’s body. It may give the wearer a 6-m equivalent head start in swimming competition by dampening turbulence in the immediate layer of water, next to the skin.

- SPEEDO swimsuit to mimic a shark’s skin. Known as FASTSKIN

- The idea is that water escapes along these channels.

Fig: 4 Shark skin feature inspired low hydrodynamic surface drag: high efficiency swimsuits design with antibacterial effect

2.3 Spider silk inspired anti-tear fabric design:

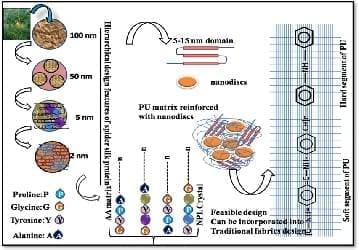

Spider (family Theridiidae) creates its web extruding proteinaceous spider silk from its spinnerets to trap the insects for feeding. Proteinaceous spider silk is one of the natural silk exhibiting unique material properties with unparalleled combinations of stiffness, strength, extensibility and toughness, exploiting hierarchical structures as exhibited in Fig. 5. The silk’s strength and flexibility come from the nanoscale crystalline reinforcement in which stiff nanometer-size crystallites are embedded and dispersed in softer protein matrices. This is unique, the way these tiny crystals are oriented towards and strongly adhere to the stretchy protein which forms their surrounding polymeric matrix.

Inspired by spider silk micro-nanocrystallite design, engineers are now able to model in the lab materials which have strength and stretchability similar to spider silk. The synthetic nanoreinforced structure emulating natural spider silk provides an opportunity to synthesize and conjugate polymer nanocomposites in future fabrics which will potentially rival the most advanced materials in nature. Using a new solvent-exchange approach that is amenable with current textile industry, engineers reinforce the hard microdomains of commercial polyurethane elastomer (a polymer or plastic consists of long chains composed of small repeating molecular units) with tiny clay discs (about 1 nm, or a billionth of a meter thick and 25 nm in diameter) .The interesting aspect of this reinforced molecular nanocomposite is that it can be easily tuned to make fibers similar to stretchy compounds such as nylon or Lycra for traditional textile industry.

Fig: 5 Schematic showing spider silk inspired anti-tear fabric design.

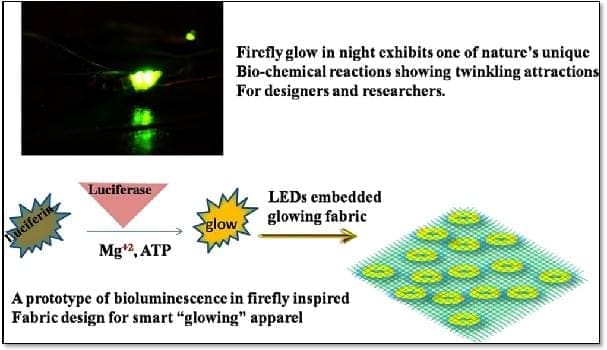

2.4 Firefly glow designed e-circuited fabrics

Light production (glow) in fireflies arises on account of an enzyme catalyzed (luciferase) bio-chemical reaction called bioluminescence. This process occurs in specialized light-emitting organs, usually on a firefly’s lower abdomen (Fig. 7). The enzyme luciferase acts on luciferin, in the presence of magnesium ions (Mg2+), adenosene triphosphate (ATP) and oxygen to produce light. This chemical process provides inciting motivation to design glowing clothes in dark that would add valuable assets to fabrics and textile industry.

Fig: 6 Learning from firefly glow: designing e-circuited luminescence in fabrics.

In this age of nano-innovation, researchers are able to produce at large scale the light-emitting devices with fabric printed circuit boards (PCBs) and successfully connect them with wearable display format using socket buttons. Thus, enabling firefly glow in fancy dresses, utilizing electronic textile engineering (e-fabric) design.

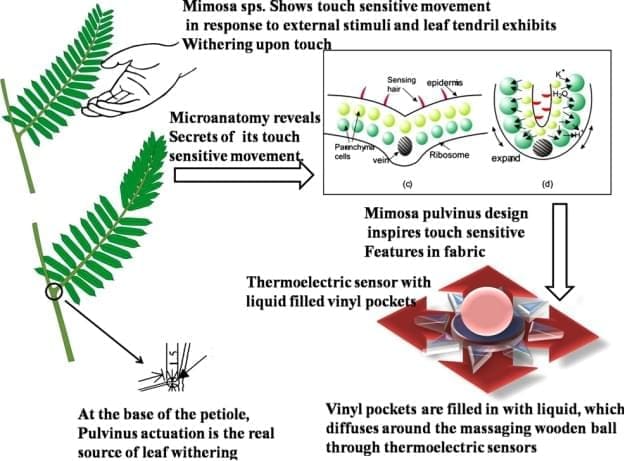

2.5 Touch sensitive apparel design

Touch sensitive plant Mimosa pudica shows human muscle’s actin–myosin like quick sensing and actuation with its leaf-moving muscle, so-called pulvinus which performs touch sensitive hydraulic actuation. Pulvini are swollen part at the base of Mimosa leaf stalks or petioles which act as autonomous organ, housing mechano- and photoreceptors that enables leave to move in response to external stimuli. Anatomically, all pulvini comprise thick walled, water-conducting vascular tissue, surrounded by thin walled motor cells. These specialized cells undergo visible swelling and shrinking, actuated by changes in turgor pressure and rapid growth expansion across leaf epidermis involving ion transport as shown in Fig. 7. This exhibits one of the remarkable weathering phenomena in plant tissue when touched and exemplifies the fastest plant movements.

Mimosa pulvinus mediated touch sensitive actuation put forth an enormous opportunity to design fabrics which shrink and de-shrink in response to external stimuli such as touch, sound and/or light. In fashion industry, this would represent a dream opportunity to come true when models walking on ramp will show folding–unfolding modes of smart fabrics with novel sensing capacity. Adopting functional mimesis to the Mimosa leave pulvinus, researchers have designed haptic fabrics by knitted smart materials with touch therapy features. Such wearable fabrics equipped with actuators and sensors perform artificial massaging and aromatizing functions while walking. Most important, such fabrics could provide a sympathetic side of apparel design by attending, understanding and responding to another person’s emotional expressions, a fundamental requisite of elderly person, spending lone time in hospitals.

Fig: 7 A scheme showing touch sensitive apparel design inspired by touch-me-not (Mimosa sps.) pulvinus features.

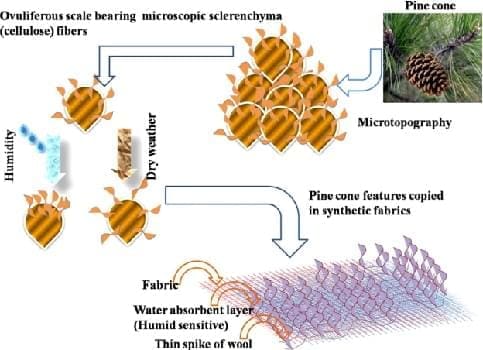

2.6 Pine cone inspired hygroscopic movements to design smart breathing fabrics

The scales of seed-bearing pine (Pinus radiate) cones move in response to changes in relative humidity. This hygroscopic movement is motivated by a structural–functional mechanism at the base of each seed petal or scale (that houses the developing seed) of the pine cone. When dries, it automatically opens up by moving away the scales gape, facilitating release of the cone’s seed. Whereas when it is kept in moist (damp) environment, scales close up (Fig. 8.) Microscopic anatomy of Monterey pine cones reveal two types of scale growing from the main body of the cone the ovuliferous scale and the bract scale. The larger ovuliferous scales bear microscopic sclerenchymatous (cellulose) fibers on upper and lower surface (8–12 mm in diameter, 150–200 mm long). It respond to changes in relative humidity by opening–closing cone aperture when season changes. In addition, orientation of cellulose microfibrils between two layers of scales and their expansion in response to relative humidity further controls the vital bending of the scales, facilitating opening–closing of the cone aperture for seed dispersal.

This natural phenomenon inspired the researchers to mimic the pine cone for designing humid sensitive adaptive cloth, delivering relief from the discomfort caused by moisture in clothing microclimate as experienced in urban environments. The fabric design utilizes two layers: one of thin spikes of wool, water absorbent material which opens up when gets wet by the wearer’s sweat, like ovuliferous scale in pine. When the layer dries out, the spikes automatically close up again. An underneath second layer protects the wearer from the rain and this smart fabric works like breathing cloth, taking dry air in while closing the fabric pores and moist air out while opening. Such fabric could adapt to changing temperatures by opening up when warm and shutting tight when cold, just like a pinecone’s bract.

Fig. 8 Schematic illustration of pine cone inspired hygroscopic movements to design smart breathing fabrics.

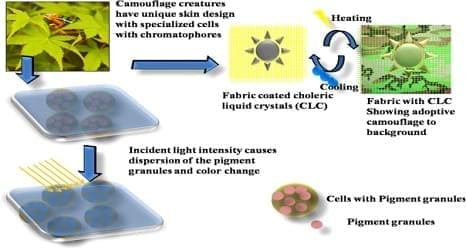

2.7 Camouflage

The phenomenon of camouflage in certain fishes and amphibian occurs due to excellent iridescent lateral stripes or spots which change their color from blue–violet under low light to green, orange and/or red under increased light intensities. The reflected indescent colors are produced by the constructive interference of light from the stacks of thin alternating transparent layers with different refractive indexes. The fish and Chameleon skin has a specialized layer of cells under their transparent outer skin which are filled with chromatophores or alternating layers of iridophores, guanine crystals. In the Chameleon, a layer of dark melanin housed in melanophores is situated in deeper skin layers and contains reflective iridophores, which exhibits phenomenal camouflage (Fig. 9).

These specialized cells filled with pigment granules are located in cytoplasm, and their beauty of the color changing capabilities lies in the efficient dispersion of the pigment granules as per changing intensity of incident light. High illumination causes the photoreceptor chromatophores to open up sodium channels and resulting accumulation of hydrated Na+ ion increases the thickness of the cytoplasmic layers. Reverse phenomenon takes place in low light illumination and variation in the wavelength of the reflected light stimulates the pigment cells to rapidly relocate their pigments and color of the skin. It gives them inherent ability to adjust their body color and remain indiscernible from the surrounding environment, i.e. camouflage. Inspired by this nature’s cryptic phenomenon, scientists have designed choleric liquid crystals (CLCs) to alter the visible color of an object to create the thermal and visual camouflage in fabrics. The color of CLCs can be changed with temperature sensitive thermocouples. The heating–cooling ability of thermocouples can be used to adjust the color of the liquid crystals to match the object’s background color, providing camouflage or adaptive concealment as schematically depicted in Fig. 10. Moreover, nature- inspired camouflage in animals has stimulated optical camouflage research in fabric design to develop and impregnate the phased optical array (OPA) like holographic designs in three dimensional hologram of background scenery, on an object to be concealed.

Fig: 9 Animated sketch of Chameleon skin derived material design approach for camouflage apparel (military defense).

- 8 Self healing fabric

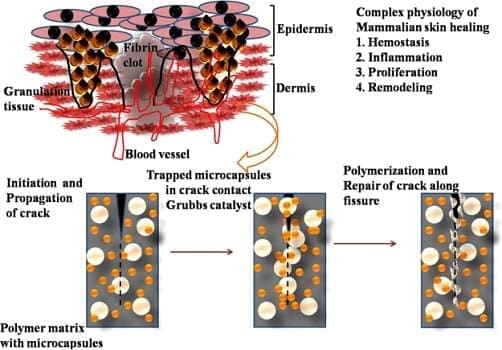

Self healing fabric design inspired by nature’s healing mechanism in mammalian tissueNature’s self healing ability has inspired new ideas and mechanism which are of fundamental interests for the engineers in designing self healing fabric. Healing process in mammals is much complex and involves hemostasis (arrest of bleeding), inflammation (recruiting immune cells to clear of any microbial population and cell debris), proliferation (growth of new tissue), and remodeling (retaining tissue shape like before injury) Fig. 11. All these events take place spontaneously and autonomously in ordered phases, triggered by injury processes at wound site albeit healing process is time consuming. Moreover, in mammals, the intrinsic mechanism of healing evolved around the chemical reactions of a series of active enzyme cascades and their inactive precursors, known as clotting factors. An important aspect of the mammalian healing is the rapid hemostatic response to arrest the bleeding and thereafter actual tissue and skin healing starts which is a more lengthy process. In mimicking bio-inspired self-healing program, a reasonably rapid response is required to restore the degree of structural integrity or prevent crack propagation while applying it to fabric design. In addition, mimicking such enormously complex and lengthy process for smart fabric design has limitations due to the lack of replenishment of the engineering components in the system designed for self-healing fabrics.

Nonetheless, nature’s healing machinery has inspired chemists/ engineers to propose new ideas and mechanisms with different healing concepts which offer the ability to restore mechanical performance of materials via fusion of the failed surfaces. Using biological bleeding approach to healing, White et al. has created the microcapsules reinforced with hollow fibers, polymer composites. This lightweight material exhibits high stiffness and superior elastic strength over the conventional materials. Microencapsulation of self-healing components involves the use of a monomer, dicyclopentadiene (DCPD), stored in urea–formaldehyde microcapsules dispersed within a polymer matrix. When microcapsules are ruptured by a progressing crack, monomer is drawn along the fissure where it comes in contact with a dispersed particulate catalyst (ruthenium based ‘Grubbs’ catalyst), initiating polymerization, thus repair the crack. Release of active components has clearly shown the restoration of the lost mechanical properties arising from the macroscale crack within a polymer matrix. Moreover, results confirmed that the dispersion of microcapsules within composite laminate material was not detrimental to stiffness of the parent architecture. A notable advantage of the microencapsulation self-healing approach is the ease with which it can be incorporated into a bulk polymer material which could be a potential self healing reinforcement agent for the future fabrics. In another landmark approach to design smart fabrics, the selfhealing rubber like material has been designed which acts as molecular glue and seals the lost end when two broken pieces are brought together. This thermosensitive polymer material has been made by simple supramolecular chemistry of fatty acids and urea, provides an exciting opportunity to be incorporated into fabrics

Fig: 10 Self healing fabric design inspired by nature’s self-healing mechanism in mammalian tissue.

3 Conclusions

After billions of years of evolution, nature developed inventions that work, which are appropriate for the intended tasks and that last. The evolution of nature led to the introduction of highly effective and power efficient biological mechanisms. Humans have always made efforts to imitate nature and we are increasingly reaching levels of advancement where it becomes significantly easier to mimic biological methods, processes, and systems. Advances in science and technology are leading to knowledge and capabilities that are multiplying every year. These

Improvements lead to capabilities that help understand better and implement nature’s principles in more complex ways. Effectively, we have now significantly better appreciation of nature’s capabilities allowing us to employ, extract, copy, and adapt its inventions. Benefits from the study of biomimetics can be seen in many applications, including stronger fiber, multifunctional materials, improved drugs, superior robots, and many others.

The rapid growth of research motivation in bioinspired engineering and biomimetics stimulated huge interest of scientist and researchers to apply it for technological innovations. There has been a spirited past of the engineers, architect and scientist, mimicking nature based design to develop splendor and memorable discoveries in the history of mankind.

4 References

- Bar-Cohen Y. In: Biomimetics: biologically inspired technologies. Boca Raton (FL): CRC Press; 2006. p. 2–40.

- Bar-Cohen Y. Biomimetics – using nature to inspire human innovation.

Bioinspir Biomim 2006;1:1–12.

- Ahmed D. Hybridization of smart textiles in medical in medical and healthcare management. AUTEX 2009 world textile conference, _Izmir, Turkey 26–28 May, 2009.

- Bhushan B, Jung YC, Koch K. Micro-, nano- and hierarchical structures for superhydrophobicity, self-cleaning and low adhesion. Philos Trans A Math Phys Eng Sci 2009;367(1894):1631–72.

Bae GY, Jang J, Jeong YG, Lyoo WS, Min BG. Super hydrophobic PLA fabrics prepared by UV photo-grafting of hydrophobic silica particles possessing vinyl groups. J Colloid Inter Sci. 2010; 344(2):584–7.